Shaft connection type bar alignment and protection device and working method thereof

A protection device and connection type technology, applied in measuring devices, laser parts, instruments, etc., can solve problems such as easy falling and time-consuming winding, saving production costs, simplifying manufacturing processes, and improving testing. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

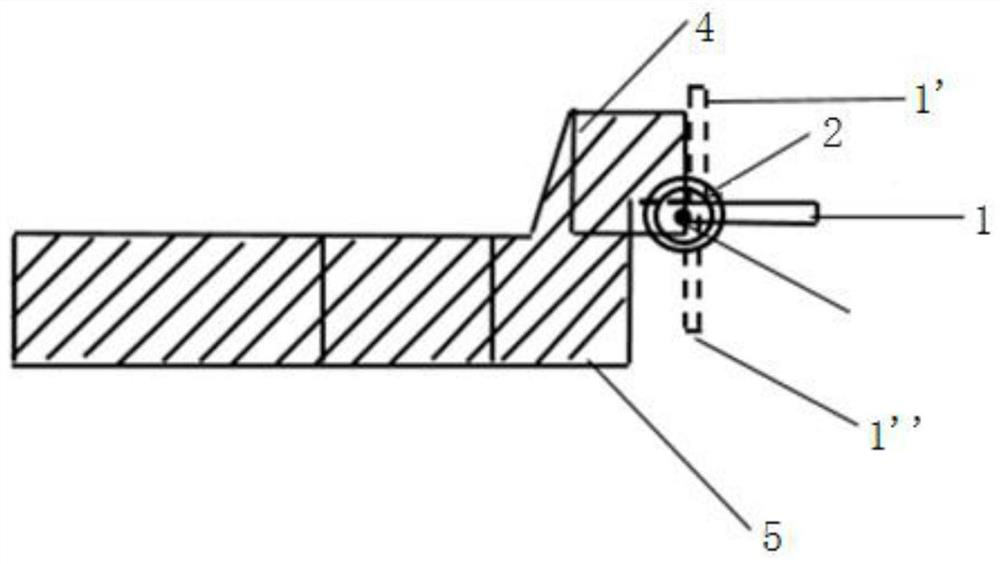

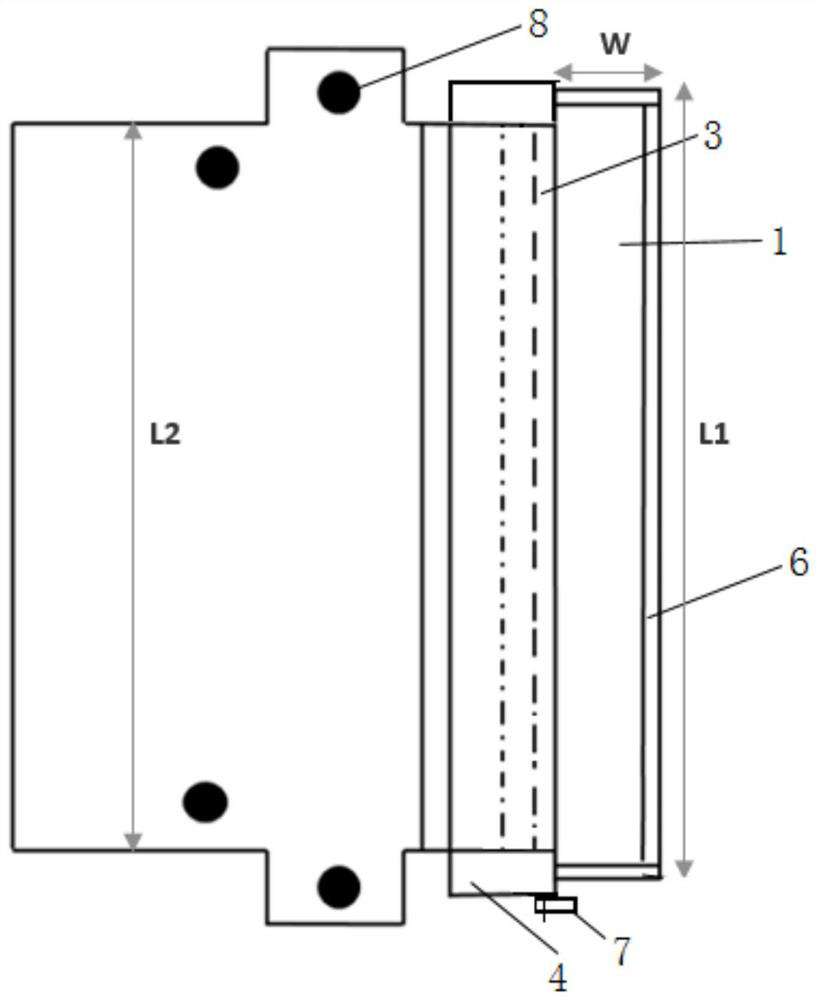

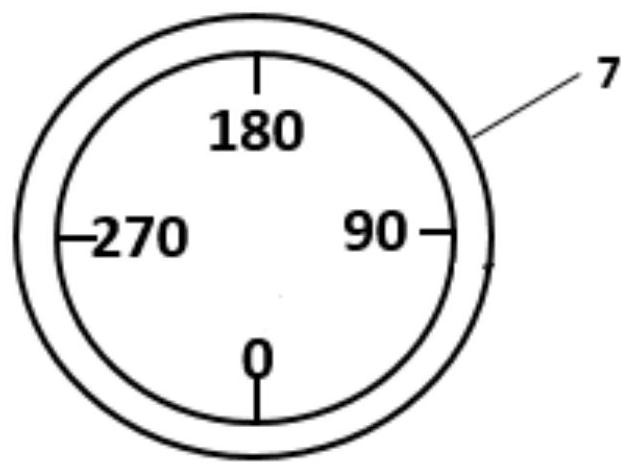

[0041] A shaft-connected bar alignment and protection device such as Figures 1 to 2 As shown, it includes a vacuum loading platform 5 and an alignment / protection plate 1, the alignment / protection plate 1 is connected to the side of the vacuum loading platform 5 close to the bar placement area 3 through a rotating shaft 2, and the vacuum loading platform is fixed by bolts 8 On the cooling table, the bar placement area 3 is provided with a vacuum port, and the bar is adsorbed on the bar placement area 3 through the vacuum port. In the present invention, the vacuum loading platform is preferably provided with 4 sets of vacuum ports. The bar is fixed on the vacuum loading platform, and each vacuum port is opened or closed separately to facilitate the winding and automatic testing of the bar, and it is stable during the probe puncture test. It is a conventional technology to absorb the bar by vacuum during the test. It will not be repeated here;

[0042] The material of the align...

Embodiment 2

[0046] A shaft-connected bar alignment and protection device, as shown in Example 1, the difference is that the alignment / protection plate 1 is made of polyester elastomer, if it is a harder material, such as a metal material , it will cause irreversible damage to the bar surface and bar end face.

Embodiment 3

[0048] A shaft-connected bar alignment and protection device, as shown in Embodiment 1, the difference is that the alignment / protection plate 1 is in the width direction (ie, the two short sides), and away from the bar placement area There are protective outer edges in the direction of the long side (that is, the long side away from the bar placement area), and the other three sides except the side connected by the rotating shaft are provided with protective outer edges, and the height of the protective outer edge 6 is 0.5cm, In order to better avoid the risk of bar falling.

[0049] In the winding stage before the puncture test, use a suction pen to take out the bar from the material box and place it at the vacuum port. During this period, the suction pen has always turned on the adsorption function. When it is placed at the vacuum port, the suction pen has the adsorption function. When closed, the adsorption force disappears, which may cause the position of the bar to be sep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com