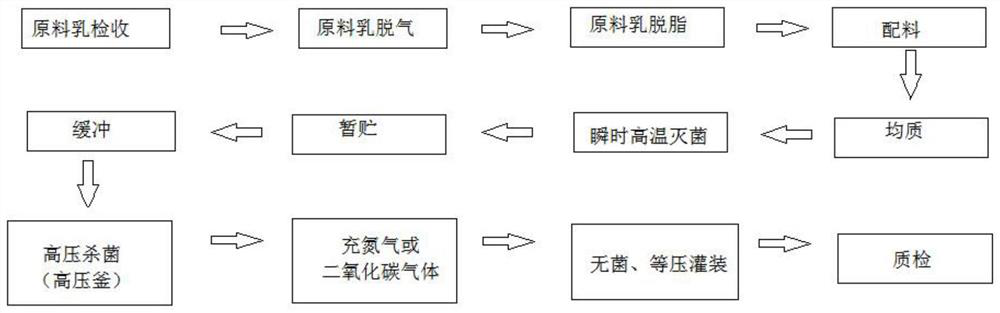

Production method of sterile steam-containing steam milk beverage

A production method and milk beverage technology, which is applied in the direction of milk preservation, milk preparations, milk substitutes, etc., can solve problems such as unsatisfactory stability of steamed milk, poor disinfection and sterilization effects, and affect the shelf life of steamed milk, etc. Taste, anti-agglomeration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0063] Ingredients: By weight percentage: skim milk powder 1-1.5%, compound stabilizer addition 0.5-1.5%, compound buffer 0.1-1.0%, and the rest are standardized raw milk.

[0064] Wherein, the composite stabilizer is formed by mixing CMC-Na:PGA:xanthan gum:β-CD in a weight ratio of 3:2:3:2;

[0065] The composite buffer is prepared by mixing sodium tripolyphosphate and sodium citrate in a weight ratio of 2:1 to 1:1.

[0066] Homogenize at 50-55°C, 20-25MPa, 500-1000r / min for 5-10s, then cool at 5°C for 2s; then sterilize at 135°C for 2s at high temperature, then cool to below 5°C for temporary storage for 2s, Then sterilize for 5s in an autoclave with a temperature of 150-170°C, a pressure of 0.25MPa and a stirring speed of 1000-2000r / min to obtain a semi-finished product. When the soda milk beverage is at 20°C, it is filled with nitrogen or carbon dioxide gas with a volume multiple of 1-2 times, and the filling pressure of 0.05-0.3Mpa is filled into cans of different specif...

Embodiment 2

[0068] Ingredients: By weight percentage: coconut milk 0.1-0.3%, skim milk powder 1-1.5%, compound stabilizer 0.5-1.5%, compound buffer 0.1-1.0%, and the rest are standardized raw milk.

[0069] Wherein, the composite stabilizer is formed by mixing CMC-Na:PGA:xanthan gum:β-CD in a weight ratio of 3:2:3:2;

[0070] The composite buffer is prepared by mixing sodium tripolyphosphate and sodium citrate in a weight ratio of 2:1 to 1:1.

[0071] Homogenize at 50-55°C, 20-25MPa, 500-1000r / min for 5-10s, then cool at 5°C for 2s; then sterilize at 135°C for 2s at high temperature, then cool to below 5°C for temporary storage for 2s, Then sterilize for 5s in an autoclave with a temperature of 150-170°C, a pressure of 0.25MPa and a stirring speed of 1000-2000r / min to obtain a semi-finished product. When the soda milk beverage is at 20°C, it is filled with nitrogen or carbon dioxide gas with a volume multiple of 1-2 times, and the filling pressure of 0.05-0.3Mpa is filled into cans of di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com