Chemical reaction kettle for efficient reaction

A chemical reaction and reaction technology, applied in the field of high-efficiency chemical reaction kettles, can solve the problems of poor stirring and mixing effect, influence of reaction efficiency, limited stirring structure density, etc., and achieve the effect of improving service life and improving reaction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

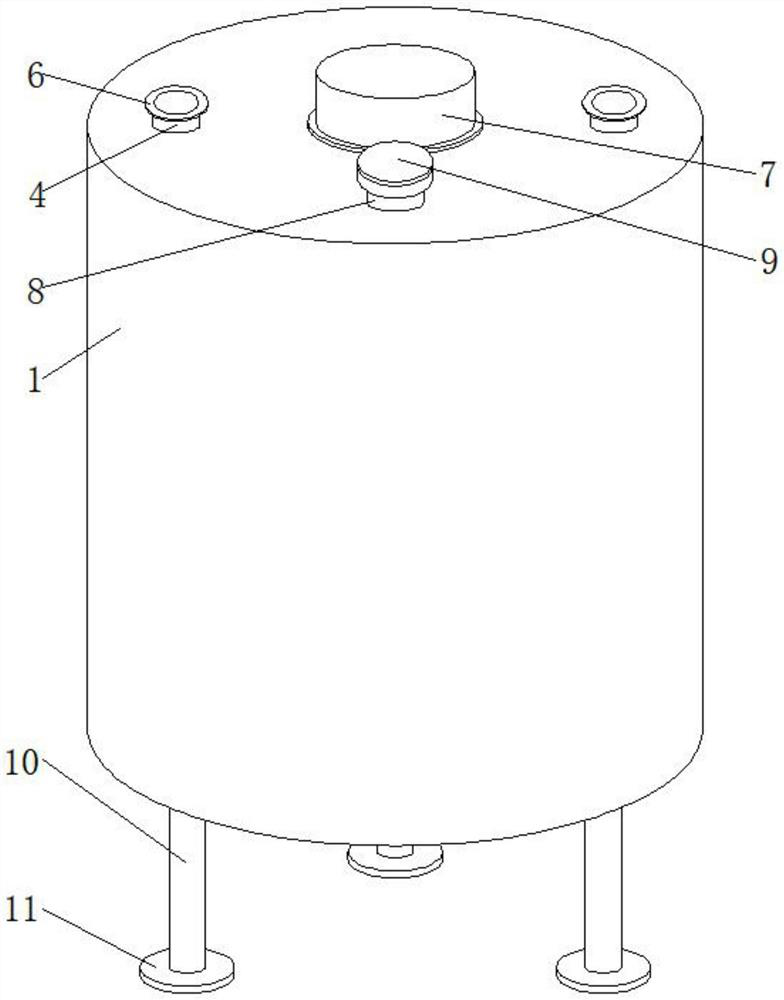

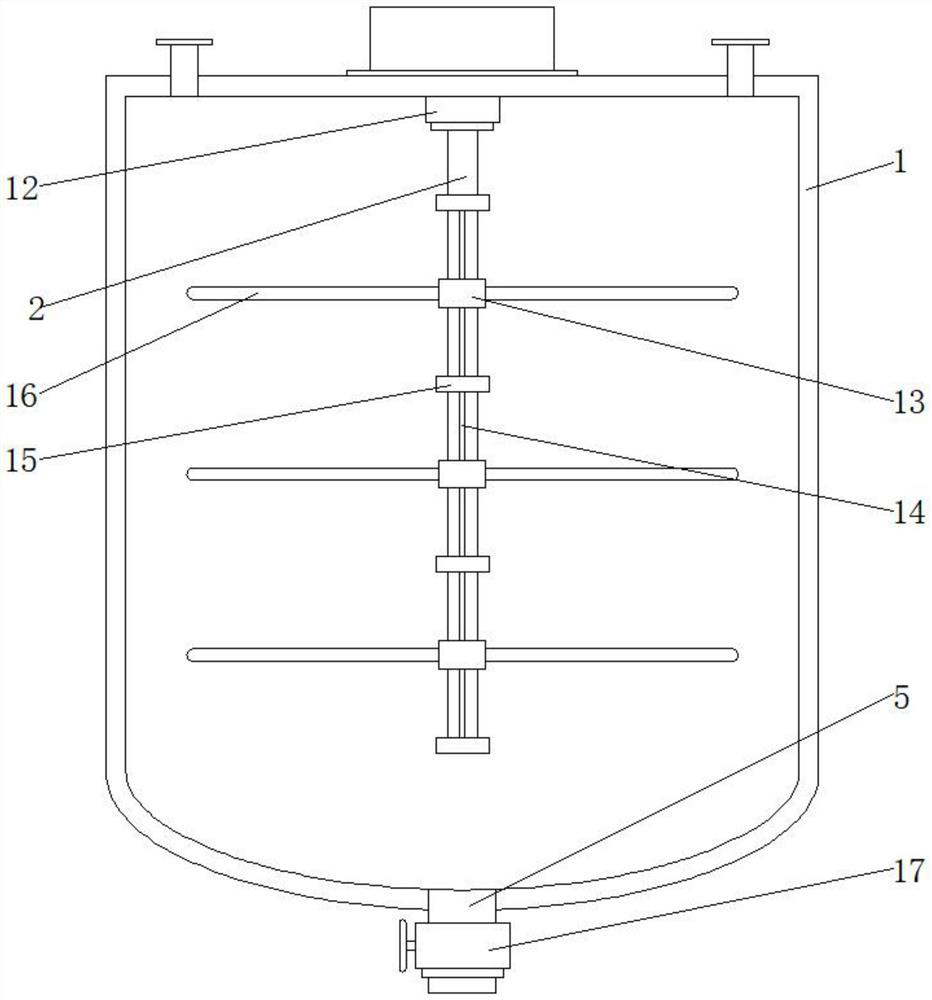

[0027] see Figure 1-4 , the present invention provides a technical solution: an efficient reaction chemical reaction kettle, comprising a kettle body 1, a rotating rod 2, a vertical groove 3, a liquid injection pipe 4 and a discharge pipe 5; the rotating rod 2 is vertically placed The interior of the kettle body 1, and the top of the rotating rod 2 is rotatably installed above the interior of the kettle body 1;

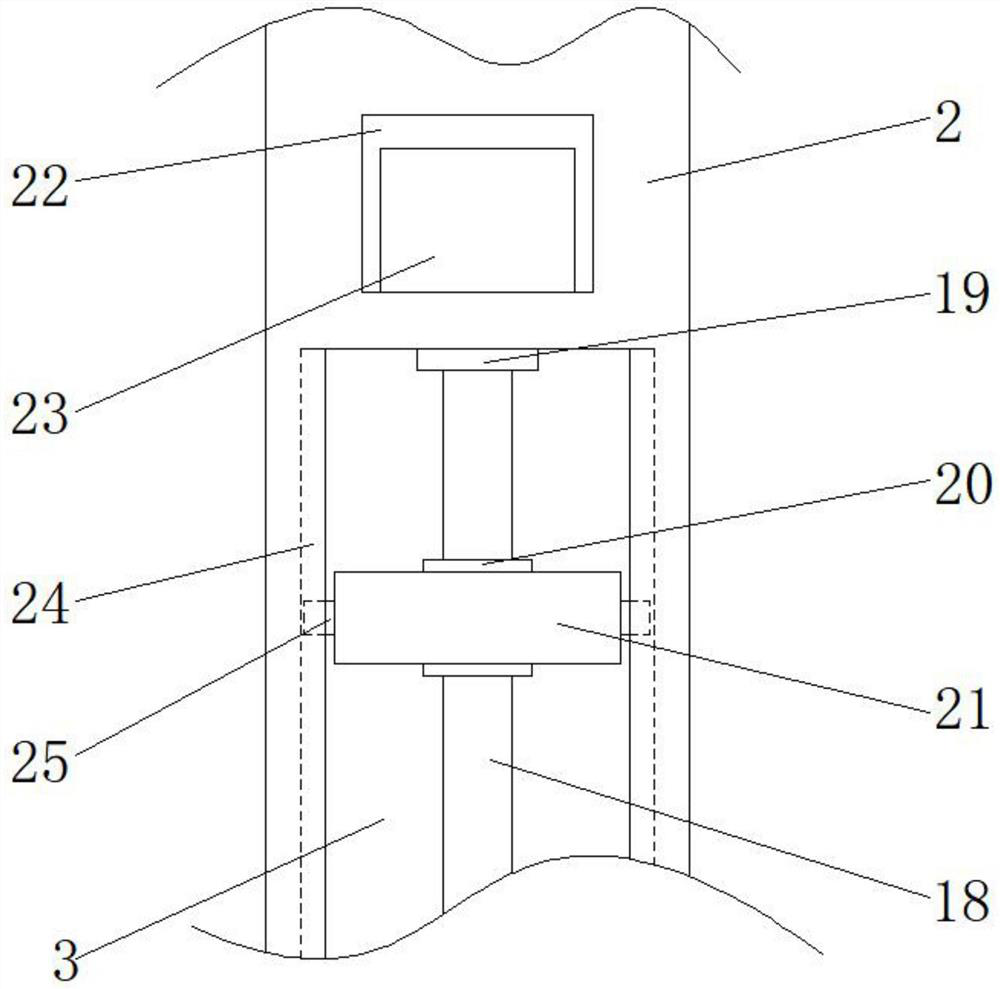

[0028] The outer ring surface of the rotating rod 2 is surrounded by a fixed limit block 15. There are four limit blocks 15. The four limit blocks 15 are evenly distributed on the outer ring of the rotating rod 2, and the limit block at the bottom is the limit block. 15 is located on the bottom outer ring of the rotating rod 2, and a convex strip 14 is vertically arranged between the limit blocks 15 on the front and rear surfaces of the rotating rod 2, and the rotating rod 2 between the upper and lower adjacent limit blocks 15 is arranged vertically. The outer ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com