Lifting-based variable pitch bearing trepanning equipment beneficial to drilling

A technology of variable pitch bearing and lift type, which is applied in the direction of drilling/drilling equipment, boring/drilling, metal processing equipment, etc., and can solve problems such as easy to walk into the air, affect processing work, and deteriorate the environment of the production workshop , to achieve the effect of improving the collection effect and avoiding excessive movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

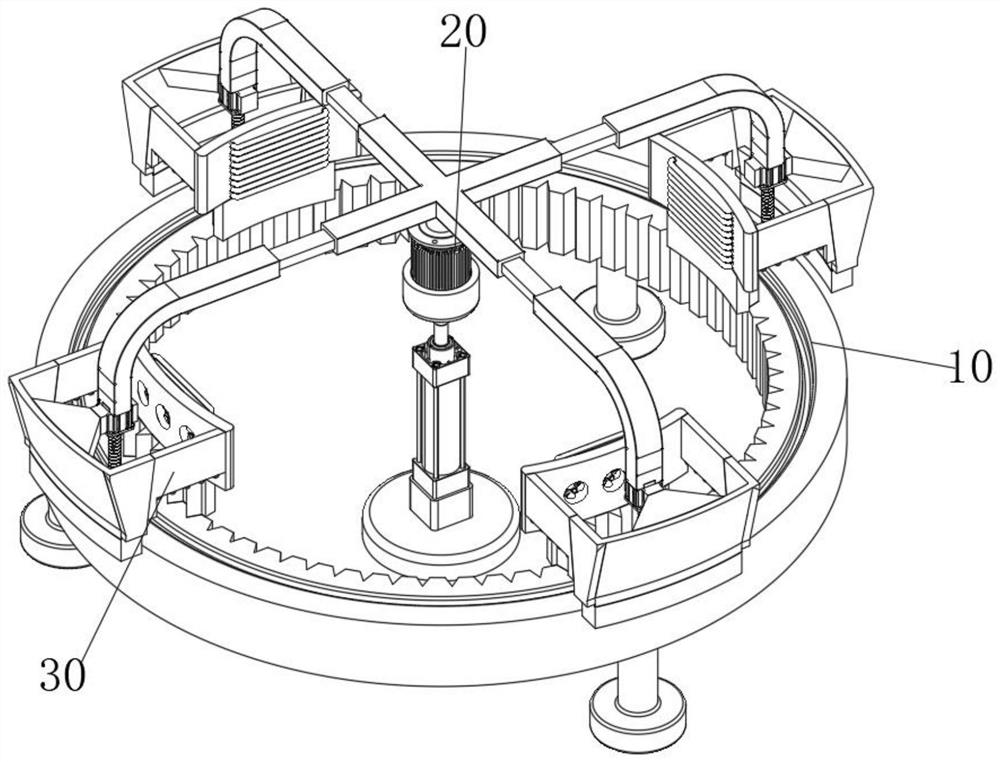

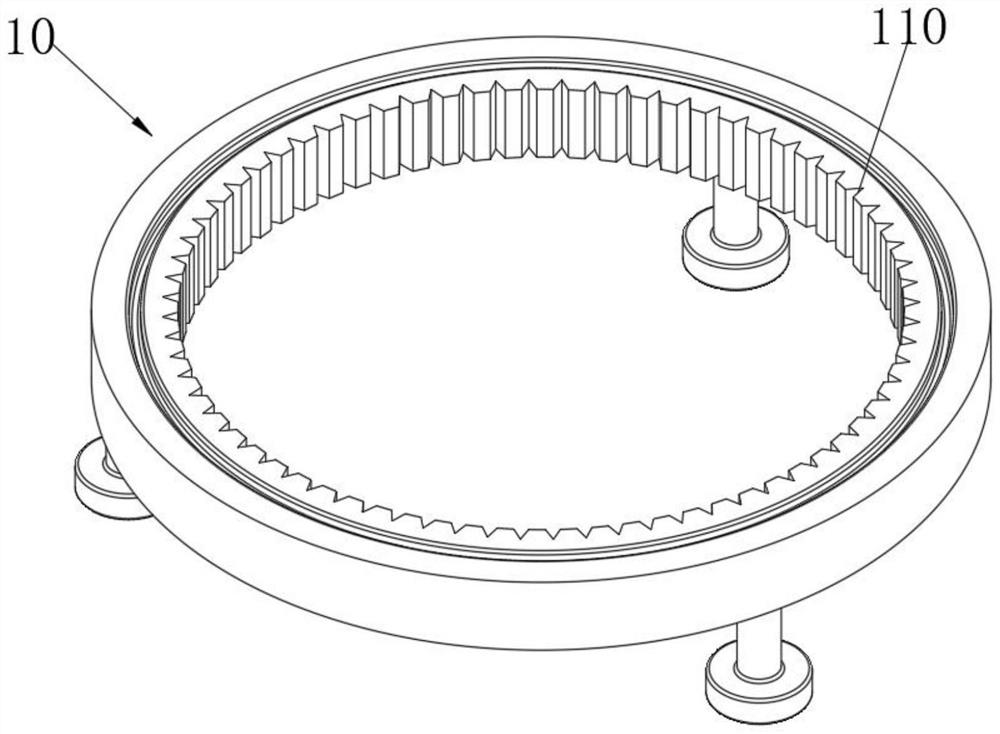

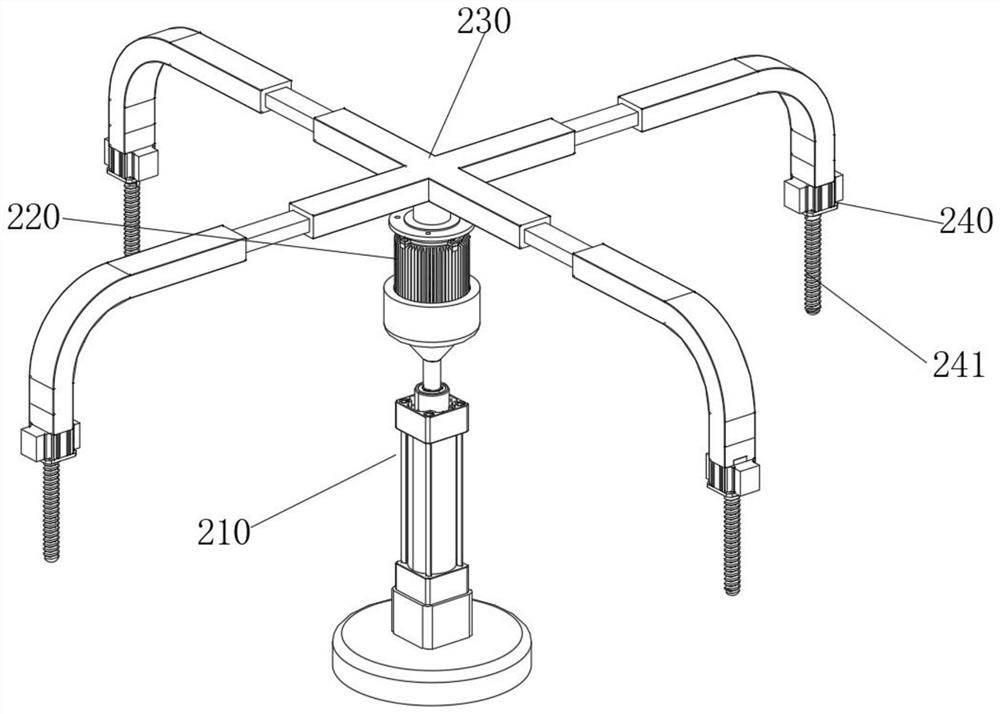

[0040] see Figure 1-Figure 10 As shown in the figure, a pitch bearing drilling device based on a lifting type that facilitates drilling is provided, including a pitch bearing body 10, a connecting assembly 20 arranged at the top of the pitch bearing body 10, and several shielding assemblies installed at the bottom end of the connecting assembly 20. 30. The connecting assembly 20 includes a lifting hydraulic rod 210. The top of the lifting hydraulic rod 210 is provided with a servo motor 220. The top of the servo motor 220 is coaxially connected to a support frame 230. Each side of the support frame 230 is provided with L-shaped rods 231. The L-shaped rods The bottom end of 231 is provided with a drilling motor 240, and the bottom end of the drilling motor 240 is coaxially connected with a drill bit 241. The shielding assembly 30 at least includes:

[0041] The inner veneer 310, the inner veneer 310 has an arc-shaped structure, one side of the inner veneer 310 is attached to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com