Full-automatic rubber blank surface paper alignment machine

A fully automatic, positioning machine technology, used in papermaking, paper/cardboard containers, container manufacturing machinery, etc., can solve the problems of low equipment structure rate, high labor cost, low efficiency of manual positioning and lamination, etc., and achieve high efficiency, The effect of reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

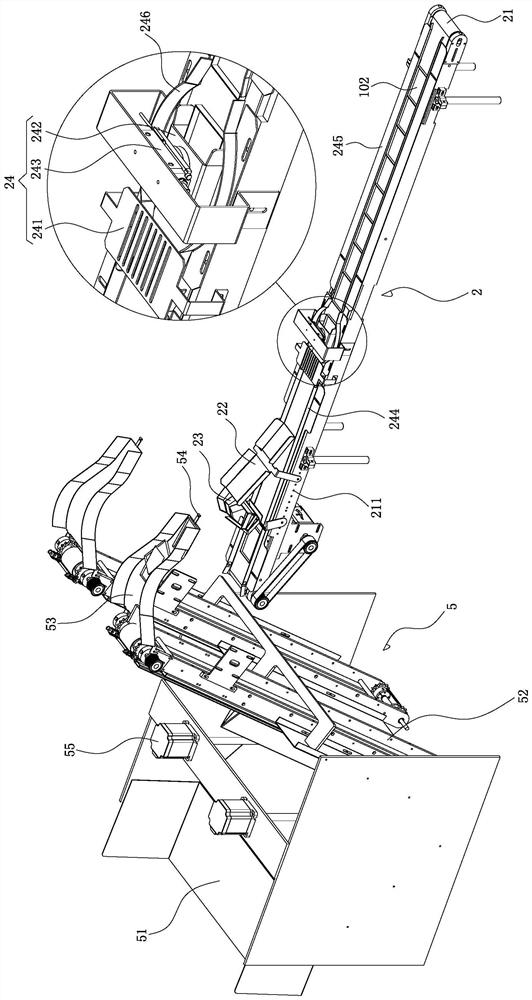

[0032] The present invention will be further described below with reference to specific embodiments and accompanying drawings. In this embodiment, the rubber embryo 102 is in the shape of a drawer, and one side of the rubber embryo 102 is provided with a transparent bright spot.

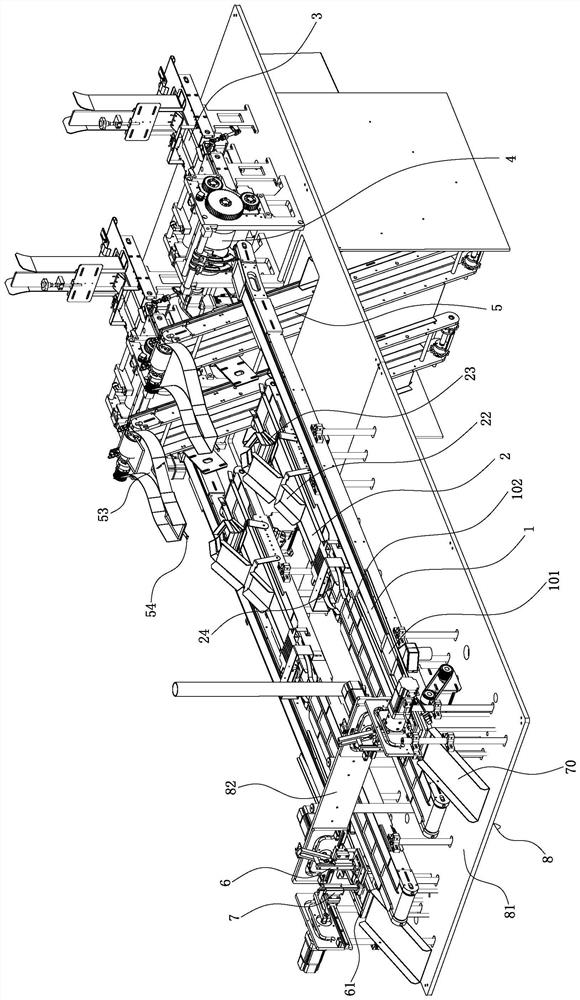

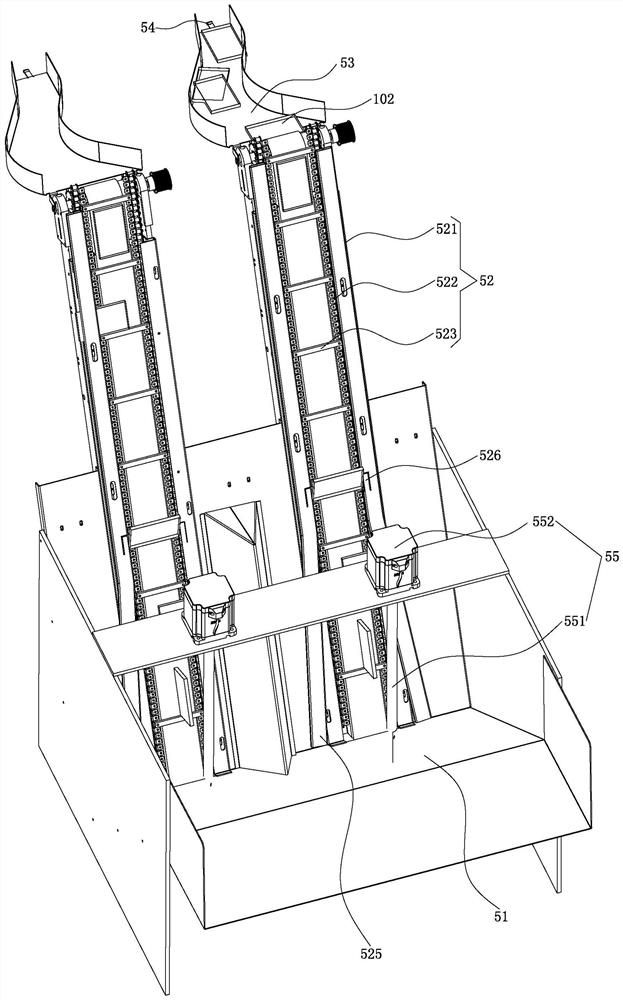

[0033] See Figure 1 to Figure 10 As shown, it is a fully automatic rubber blank face paper alignment machine, which includes: a first feeding mechanism 1 and a second feeding mechanism 2 arranged in parallel and parallel, arranged at one end of the first feeding mechanism 1 and used to automatically arrange and send out The first feeding mechanism 3 of the face paper 101, the glue brushing mechanism 4 arranged between the first feeding mechanism 3 and the first feeding mechanism 1 and used for rolling glue on the face paper 101, setting The second feeding mechanism 5, which is located at one end of the second feeding mechanism 2 and is used for automatically arranging and sending out the glue blank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com