Method for installing bridge crane main beam of pump station main power house

An installation method and the technology of the main workshop, which are applied in the direction of pumping stations, water supply devices, transportation and packaging, etc., can solve the problems of inconvenient sky anchors and ground anchors pre-embedded, heights that cannot meet the extension of crane booms, and insufficient heights, etc. High dismantling efficiency, elimination of non-standard erection behavior, and the effect of saving construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention, so as to explain the concept of the present invention, the technical problems solved, the technical features constituting the technical solutions, and the technologies brought about by the present invention. The effect has a further understanding.

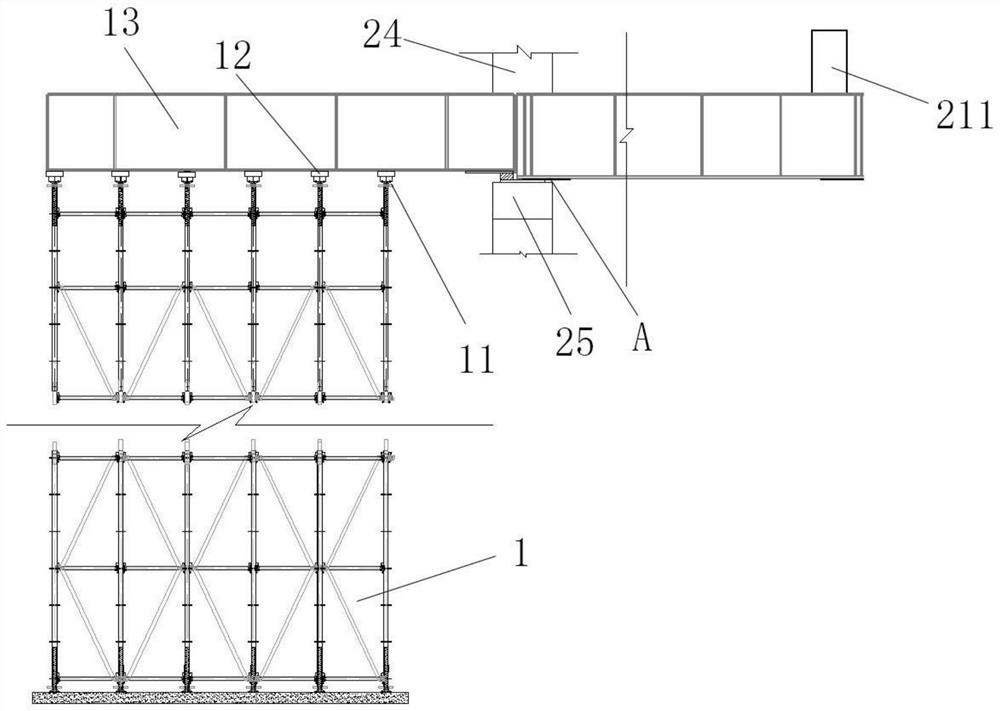

[0034] like figure 1 As shown, a method for installing a main beam of a bridge machine in a main powerhouse of a pumping station includes the following steps:

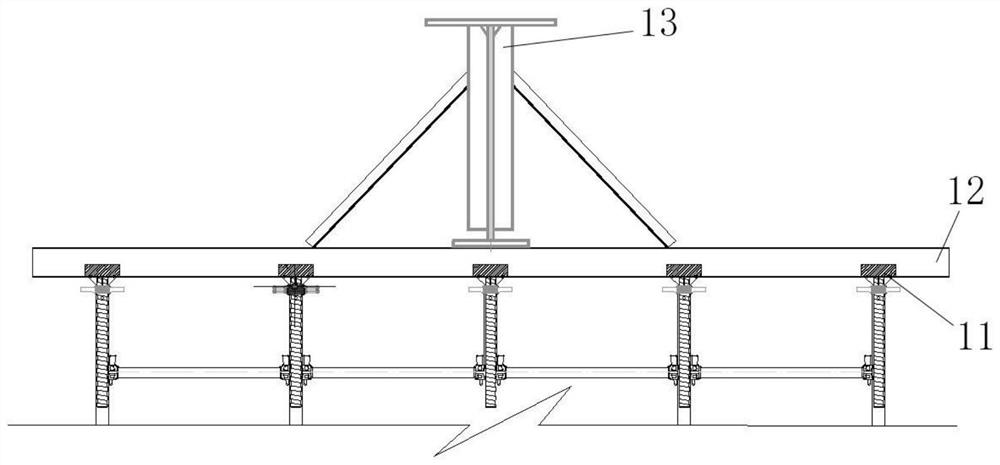

[0035] S1, the bridge machine track beam and the support system 1 are erected;

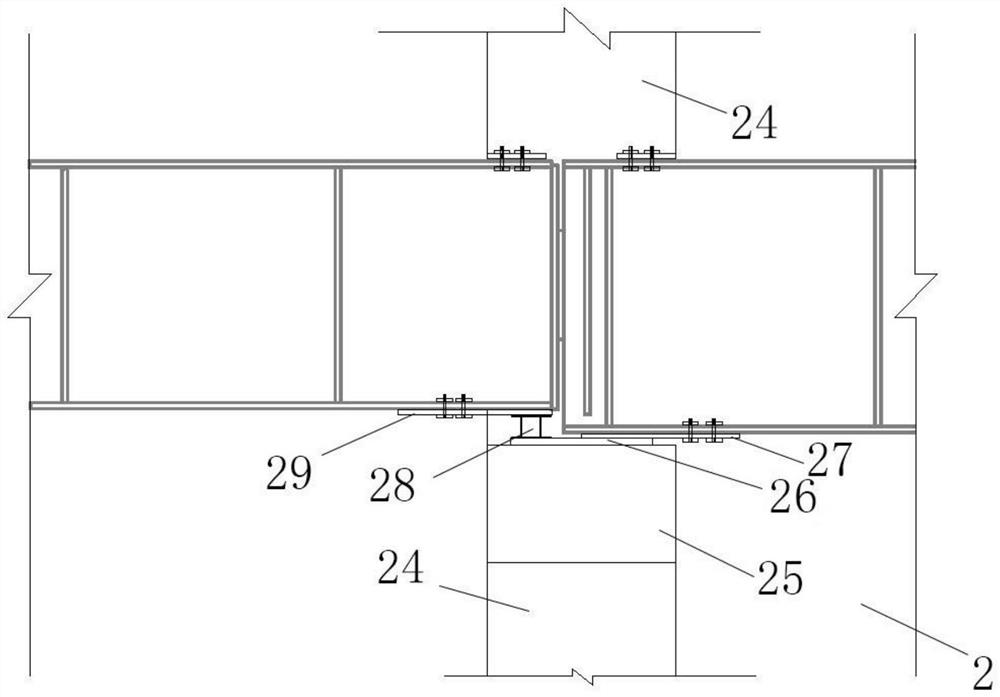

[0036] S2. The bridge machine rail beam is connected with the support system 1, and the inner and outer part of the bridge machine rail beam in the installation room 2 is connected to form a rail beam;

[0037] S3. The upstream side end beam 21 and the downstream side end beam 22 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com