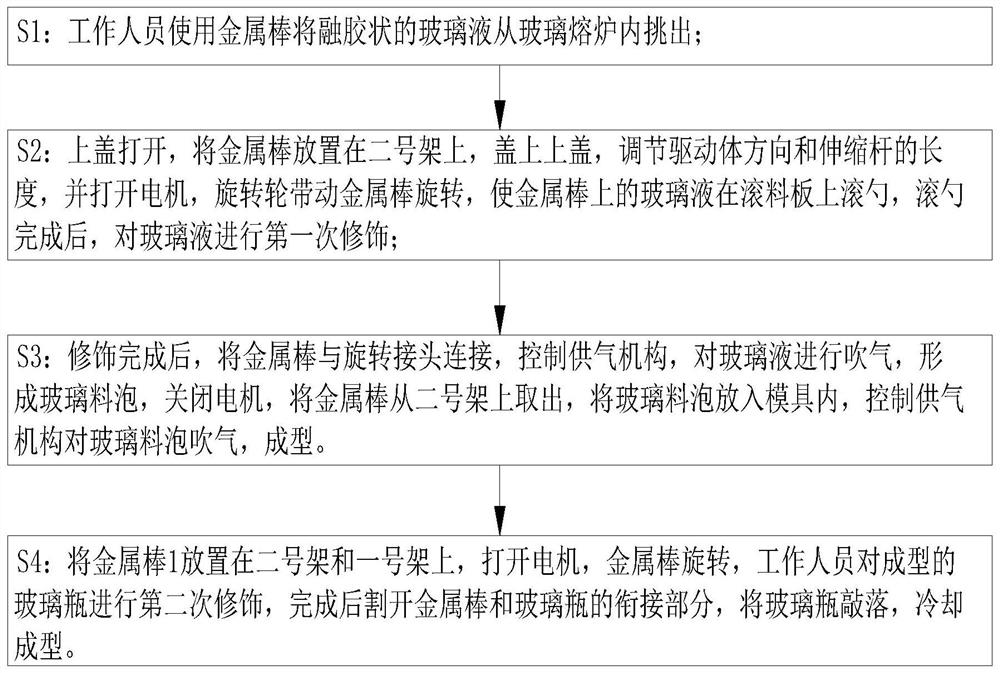

Glass bottle blowing equipment and blowing process

A glass bottle and equipment technology, which is applied in glass production, blowing-blowing glass molding machines, blowing heads, etc., can solve the problems of time-consuming and labor-intensive, easily damaged structures, and heavy steel pipes, etc., and achieve lower technical requirements, uniform friction, and lower recruitment requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

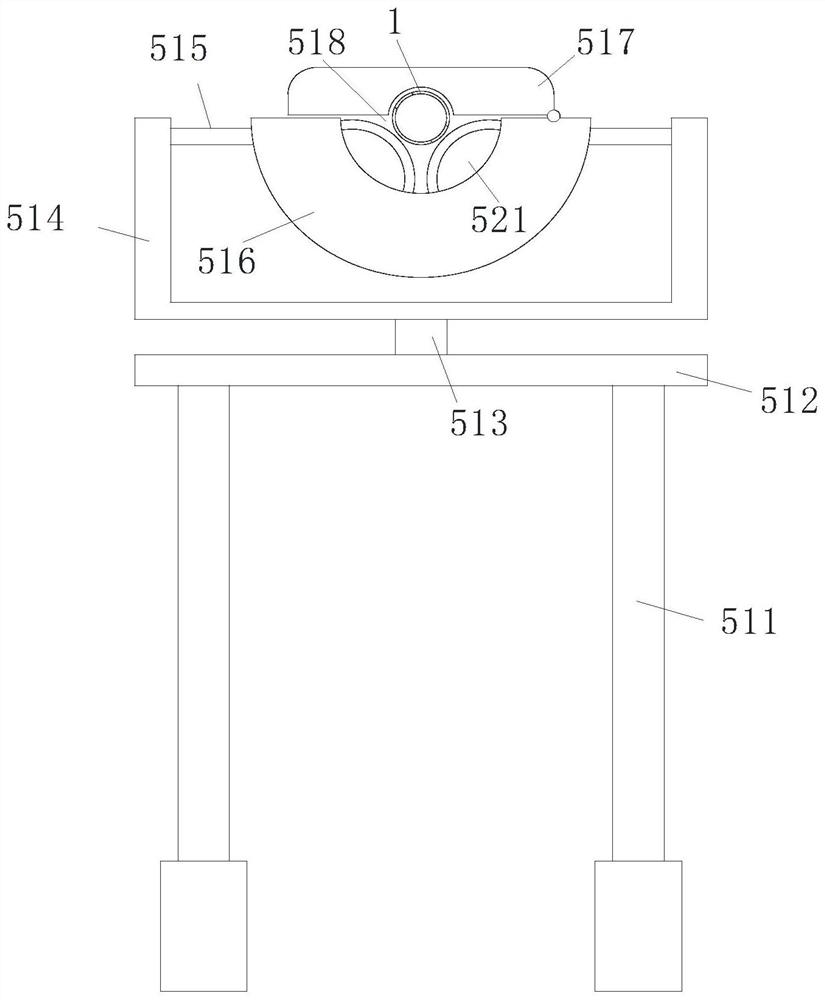

[0056] As an embodiment of the present invention, the adjustment mechanism 51 includes:

[0057] Telescopic rods 511, the number of said telescopic rods 511 is two, and is symmetrically fixed on the base 3;

[0058] A connecting rod 512, the connecting rod 512 is fixedly connected with the telescopic ends of the top of the two telescopic rods 511 at the same time;

[0059] The No. 1 rotating shaft 513, the bottom end of the No. 1 rotating shaft 513 is rotatably connected to the center position of the upper surface of the connecting rod 512;

[0060] A turret 514, the center position of the bottom surface of the turret 514 is rotatably connected to the top of the No. 1 rotating shaft 513;

[0061] The No. 2 rotating shaft 515, the No. 2 rotating shaft 515 is symmetrically arranged on the opposite side walls of the turret 514 near the top;

[0062] A driving body 516, the driving body 516 is located between the second rotating shafts 515 and is rotatably connected with the opp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com