Efficient slag treatment device for high-temperature slag waste heat recovery

A technology of waste heat recovery and treatment device, applied in the field of high temperature slag treatment, can solve the problems of reducing waste heat recovery effect, reducing recovery efficiency, reducing resource utilization rate, etc., so as to improve convenience, slow down heat loss, and improve waste heat recovery efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

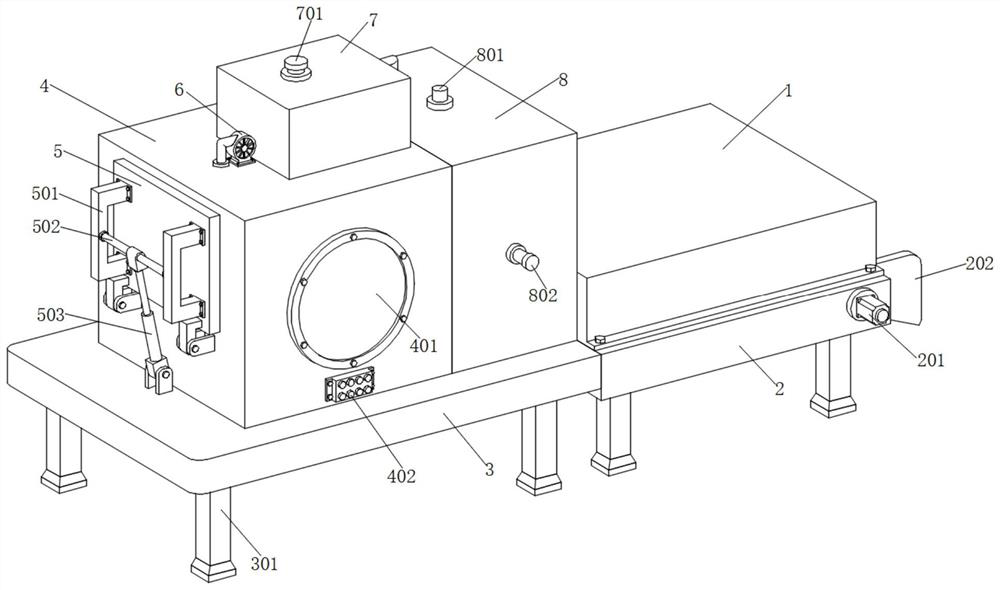

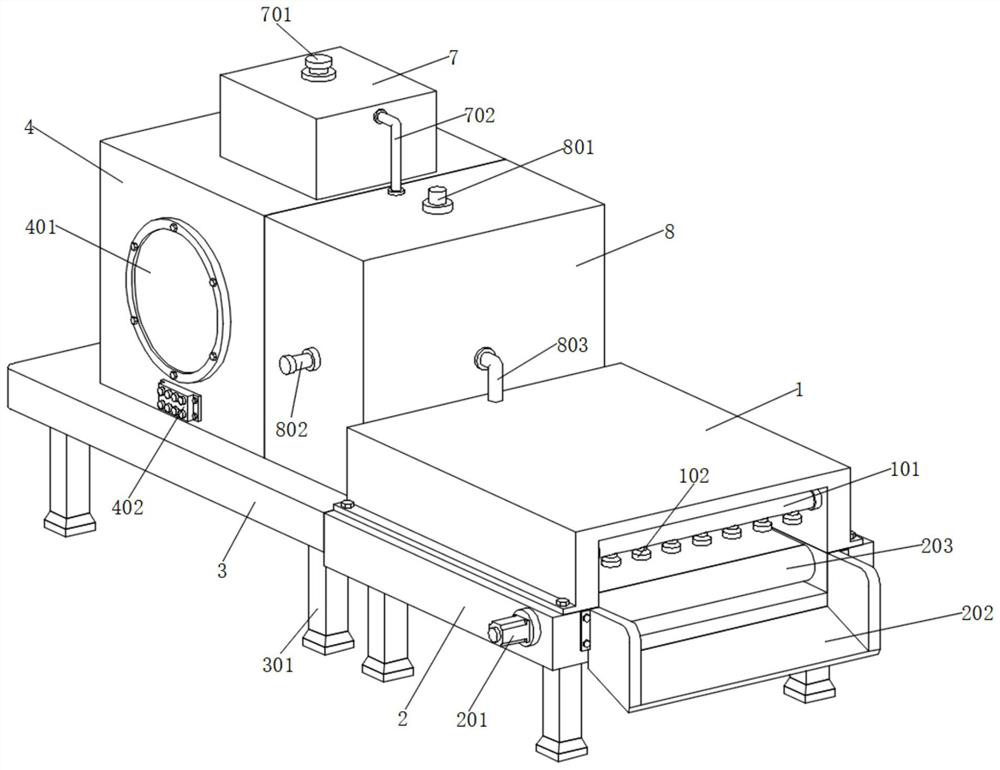

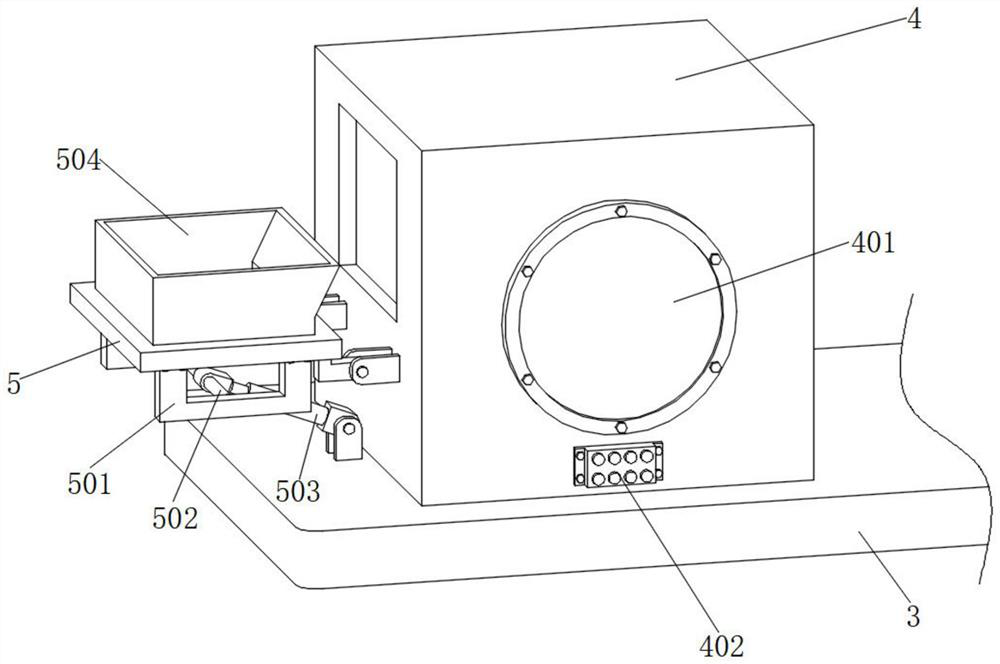

[0037] like Figure 1-8 As shown, a high-efficiency slag processing device for high-temperature slag waste heat recovery proposed by the present invention includes a conveying frame 2, a base 3 and a first processing box 4, and the base 3 and the bottom of the conveying frame 2 are fixed A support leg 301 is installed, and the base 3 and the conveyor 2 can be easily supported by the support leg 301. The top of the base 3 is fixedly installed with a first processing box 4, and one side of the first processing box 4 is movably installed with a sealing plate 5. An upper hopper 504 extending into the first processing box 4 is fixedly installed on one side of the sealing plate 5, a fixing frame 501 is fixedly installed on one side of the sealing plate 5, and a rotating shaft 502 is movably installed between the fixing frames 501, and the rotating shaft A first electric push rod 503 is movably installed between the 502 and the base 3, which can introduce the molten slag into the upp...

Embodiment 2

[0039] like Figure 1-8 As shown in the figure, a high-efficiency slag treatment device for high-temperature slag waste heat recovery proposed by the present invention, compared with the first embodiment, this embodiment also includes a fixed installation on the base 3 on one side of the first treatment box 4 There is a second treatment box 8. The inside of the second treatment box 8 is provided with a water storage chamber 804 and a heating chamber 807. The water storage chamber 804 is located on the top of the heating chamber 807. A second water injection port 801 corresponding to the water storage chamber 804 is fixedly installed on the top of the second treatment tank 8, and water can be easily introduced into the water storage chamber 804 for storage through the second water injection port 801. The bottom of the heating chamber 807 is movably installed. There is a pushing frame 808 corresponding to the vibration frame 10, and the vibration of the vibration frame 10 can be...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap