Preparation method of cetrorelix acetate freeze-dried preparation

A technology of cetrorelix acetate and freeze-dried preparations, applied in the field of pharmaceutical preparations, can solve the problem of high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

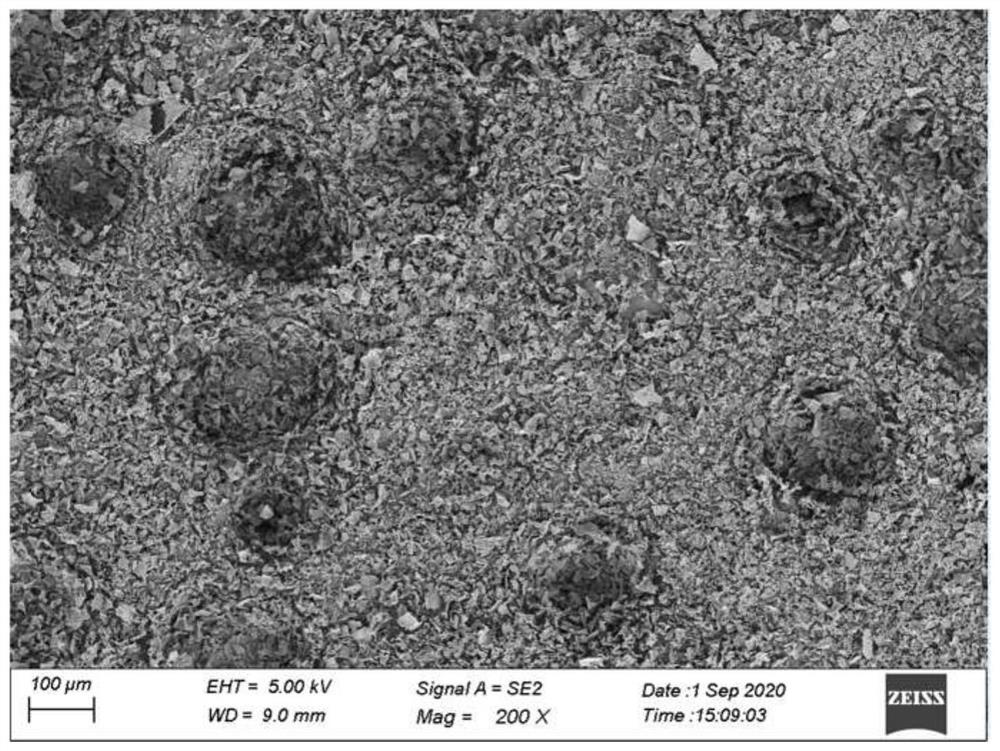

Image

Examples

Embodiment 1

[0051] Step 1: Preparation of Cetrorelix Acetate Liquid for Injection

[0052] Accurately weigh 28.1mg of cetrorelix acetate, put it in a 50ml beaker, add 30% acetic acid solution, dissolve, transfer to a 100ml beaker containing 50ml water for injection, add 5.48g of mannitol, dissolve and prepare this solution with water for injection. 102g; immediately filter the feed solution with a 0.2μm filter membrane under aseptic conditions and dispense it into a washed colorless 2ml injection bottle and plug it with a sterile freeze-drying stopper, the filling volume is 1.0ml (1.021g).

[0053] Step 2: Freeze-Drying Process

[0054] Specific steps are as follows:

[0055] 1) Freezing stage: 1.0°C / min plate temperature to 0°C, hold for 15min, continue to cool down to -40°C at 1.0°C / min, hold for 2h, and then continue to cool down to -45°C at a cooling rate of 1.0°C / min ℃, keep warm for 0.5h;

[0056] 2) Annealing stage: the temperature of the plate layer is raised to -20°C at 1.0°C / ...

Embodiment 2

[0060] The preparation of cetrelix acetate liquid medicine for injection is the same as the first step of Example 1.

[0061] Step 2: Freeze-Drying Process

[0062] 1) Freezing stage: cool down to -45°C at a temperature of 1.0°C / min and keep the temperature for 3h;

[0063] 2) Annealing stage: the temperature of the plate layer is raised to -10°C at 2.0°C / min, and the holding time is 0.5h; the temperature of the plate layer is lowered to -40°C at 2.0°C / min, and the holding time is 1h;

[0064] 3) sublimation stage: the pressure is 15Pa, the temperature of the plate layer is heated to -10°C at 0.8°C / min, and the holding time is 12h;

[0065] 4) Drying stage: the temperature of the board layer was raised to 15°C at 1.5°C / min, and the holding time was 10h.

Embodiment 3

[0067] The preparation method of cetrorelix acetate liquid medicine for injection is the same as that of the first step of Example 1.

[0068] Step 2: Freeze-Drying Process

[0069] 1) Freezing stage: Decrease the plate temperature to -5°C at 2.0°C / min and keep it for 10min; continue to cool down to -35°C at a cooling rate of 2.0°C / min and keep it for 3h; then continue to cool down to -35°C at 2.0°C / min 40 ℃, heat preservation 0.8h.

[0070] 2) Annealing stage: the temperature of the plate layer is raised to -15°C at 1.5°C / min, and the holding time is 0.7h; the temperature of the plate layer is lowered to -44°C at 1.5°C / min, and the holding time is 0.5h;

[0071] 3) sublimation stage: the pressure is 18Pa, the temperature of the board is heated to -15°C at 0.9°C / min, and the holding time is 11h;

[0072] 4) Drying stage: the temperature of the board layer was raised to 18°C at 1.2°C / min, and the holding time was 9h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com