Heating equipment and stamping process of high-strength steel medium-thickness plate blank for automobile axle housing

A technology for heating equipment and high-strength steel, applied in the field of stamping and forming, can solve the problems affecting the forming quality of the axle housing, high energy consumption and production costs, cracking, scratches, etc., to prevent cracking, reduce production costs, and reduce mold wear. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

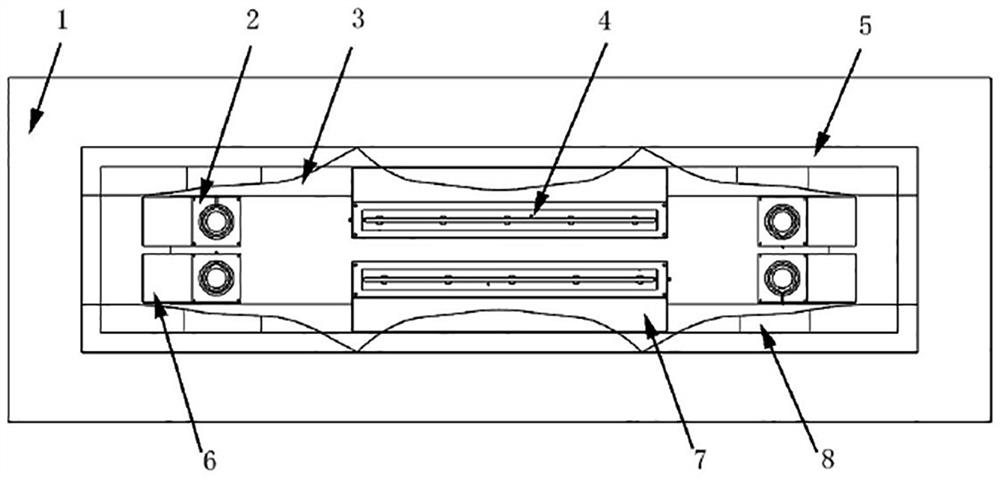

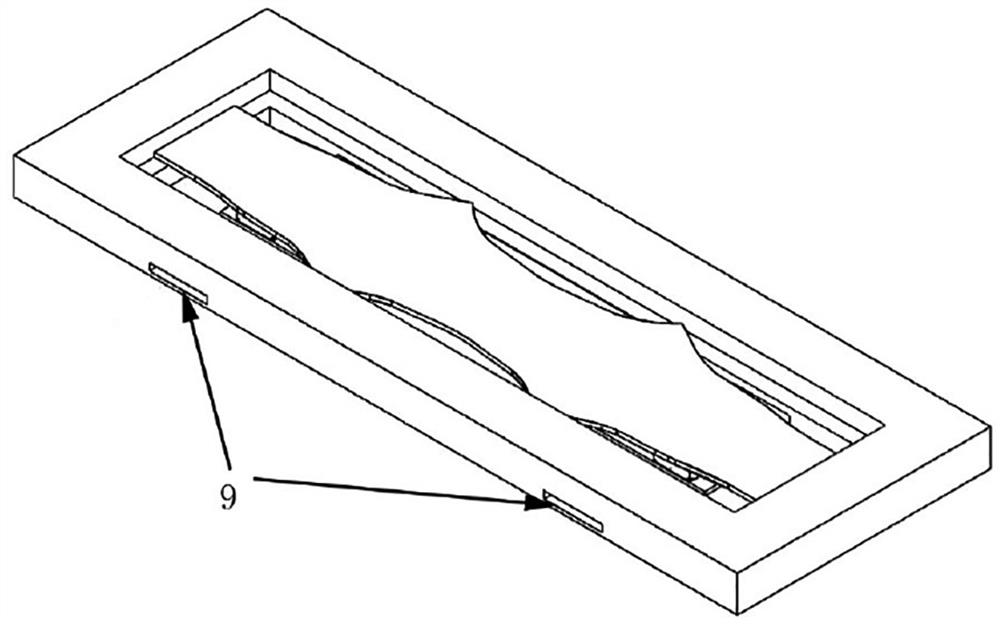

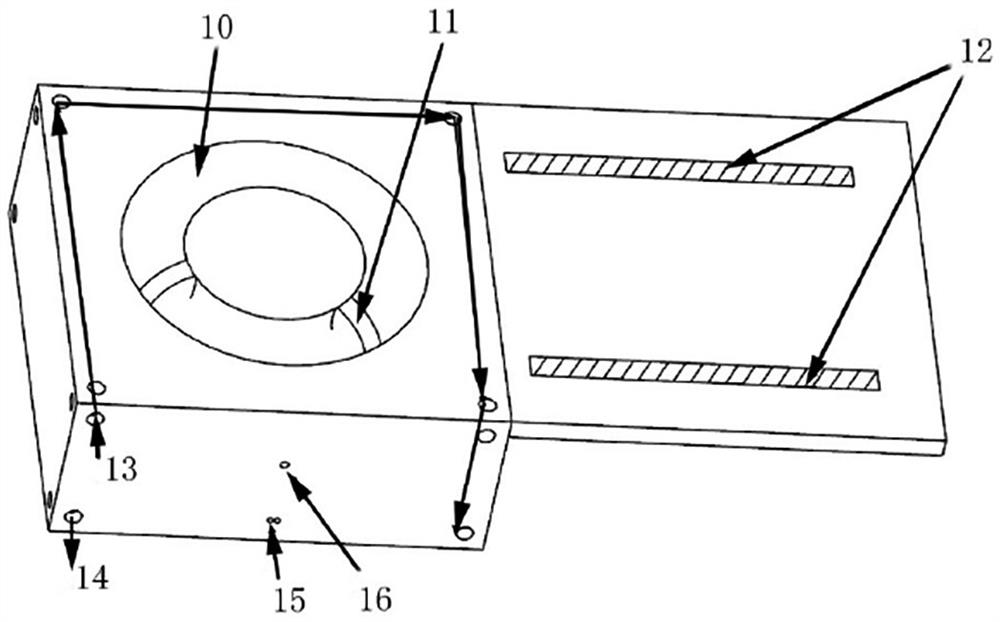

[0036] like Figure 1~Figure 9 As shown, the embodiment of the present invention provides a heating equipment for high-strength steel medium-thick slabs for automobile axle housings. The differential temperature stamping process. The heating equipment includes an outer casing 1, and a ring-shaped heating module 2 is arranged at the transition 28 of the square and circle of the slab 3 in the outer casing 1, and a linear heating module 4 is arranged at the bending place 27 of the bridge bag. The annular heating module 2 and the linear heating module 4 are used to adapt to different types of slabs 3; the annular heating element 11 is installed in the annular heating module 2, and the linear heating element 22 is installed in the linear heating module 4. The cross section of the inner wall of the heating module The outlines are all elliptical, and the slab 3 and the heating element are located at the two foci 18 of the elliptical section respectively to maximize the heating effic...

Embodiment 2

[0045] like Figure 10 As shown, the embodiment of the present invention provides a stamping process of a high-strength steel medium-thick slab 3 for an automobile axle housing, and the stamping process adopts the heating equipment in the first embodiment. The differential temperature heating process system of slab 3 is comprehensively determined according to the heat dissipation conditions of the production site environment, the blank transfer interval, and the thickness of the sheet. , the punch 25 and the concave die 26 of the punching machine correspond to the inserts at the forming positions of the bending part 27 of the bridge bag and the transition part 28 of the square and circle, which need to be processed by heat-resistant high-temperature alloys.

[0046] The stamping process includes:

[0047] S100, before stamping, the circulating cooling system is turned on, the annular heating module 2 and the linear heating module 4 are turned on, the atmosphere protection sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com