Anti-curing oil storage tank for oil field and using method

A technology for oil storage tanks and oil fields, which is applied to tank trucks, sustainable packaging, containers, etc. It can solve the problems of surrounding environmental pollution, increase costs, and affect single well production, and achieve good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

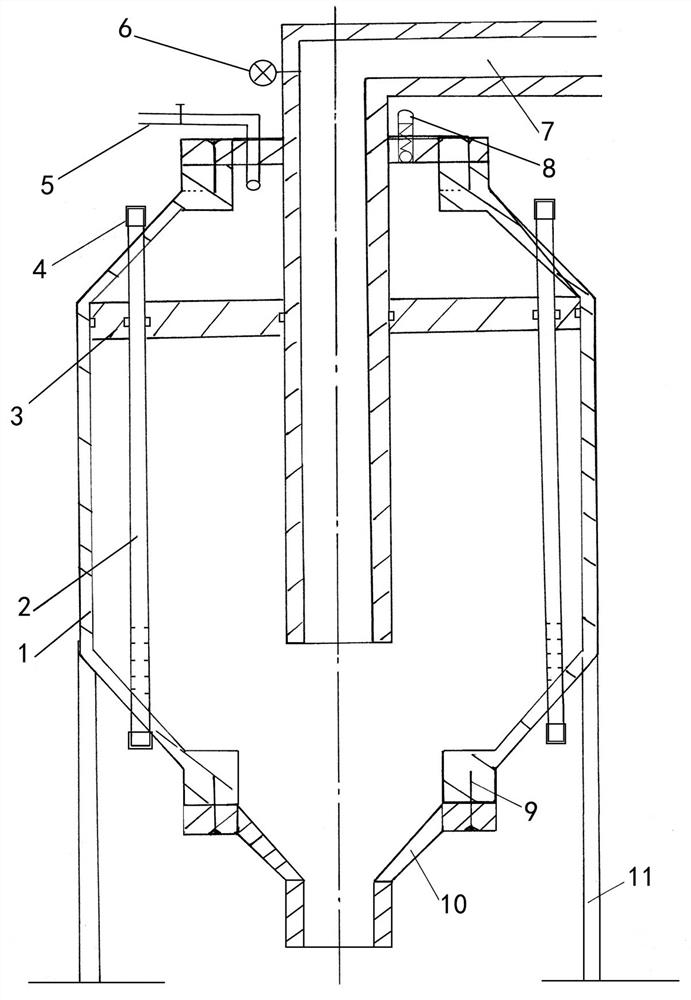

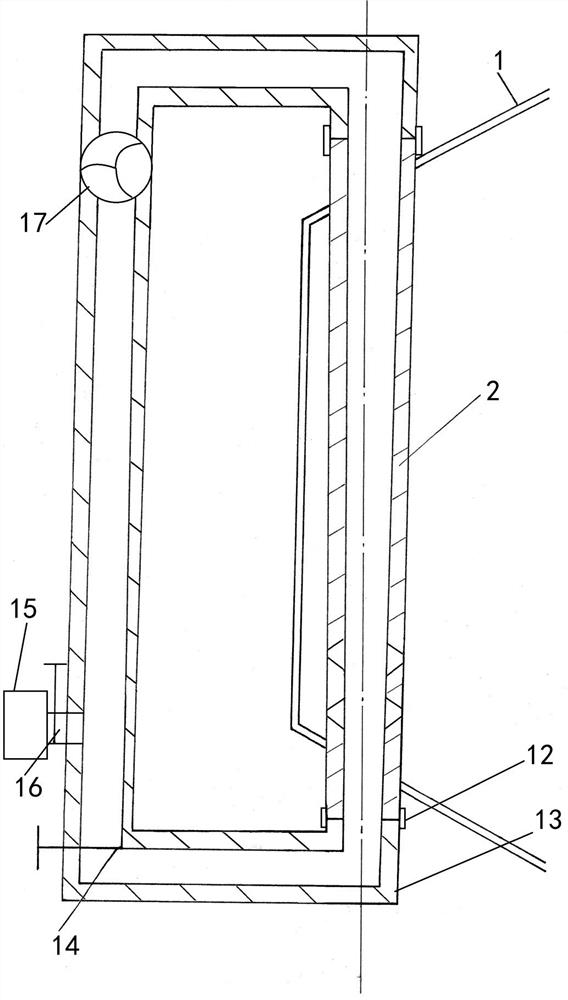

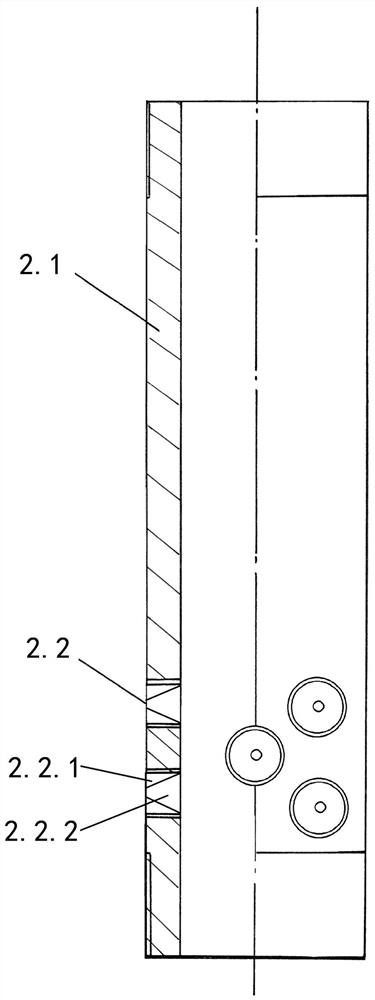

[0034] Example 1, refer to Figure 1-4, An oilfield anti-solidification oil storage tank mentioned in the present invention includes a tank body 1, a liquid discharge pressure plate 3, a compressed gas inlet and outlet pipe 5, a pressure gauge 6, a liquid inlet pipe 7, a safety valve 8, a connecting bolt 9, The liquid discharge pipe 10, the bracket 11, the tank body 1 is installed and fixed by the lower bracket 11, the upper end of the tank body 1 is provided with a liquid inlet pipe 7 and a compressed gas inlet and outlet pipe 5, and the lower end is fixed by a connecting bolt 9 with a discharge pipe. The liquid pipe 10 is provided with a liquid discharge pressure plate 3 in the inner cavity of the tank body 1, and the lower end outlet of the liquid inlet pipe 7 is located in the lower part of the inner cavity of the tank body 1, which also includes a permeation dilution pipe 2, a sealing blind plug 4, The external connection head 12, the oil return pipe 13, the pressure hold...

Embodiment 2

[0044] Embodiment 2, a kind of oilfield anti-solidification oil storage tank mentioned in the present invention, its technical scheme is: comprise tank body 1, liquid discharge pressure plate 3, compressed gas inlet and outlet pipes 5, liquid inlet pipes 7, connecting bolts 9, The liquid discharge pipe 10, the bracket 11, the tank body 1 is installed and fixed by the lower bracket 11, the upper end of the tank body 1 is provided with a liquid inlet pipe 7 and a compressed gas inlet and outlet pipe 5, and the lower end is fixed by a connecting bolt 9 with a discharge pipe. The liquid pipe 10 is provided with a liquid discharge pressure plate 3 in the inner cavity of the tank body 1, and the lower end outlet of the liquid inlet pipe 7 is located in the lower part of the inner cavity of the tank body 1, which also includes a permeation dilution pipe 2, a sealing blind plug 4, The external connection head 12, the oil return pipe 13, the pressure holding valve 14, the external fuel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com