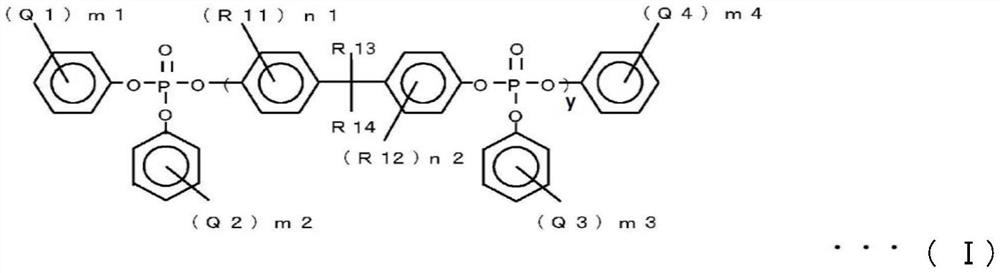

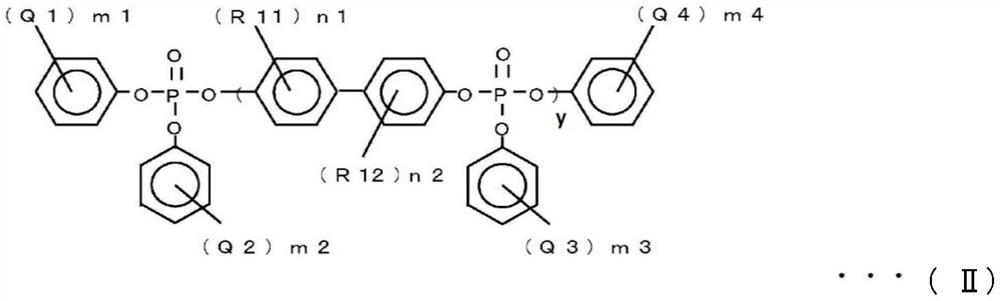

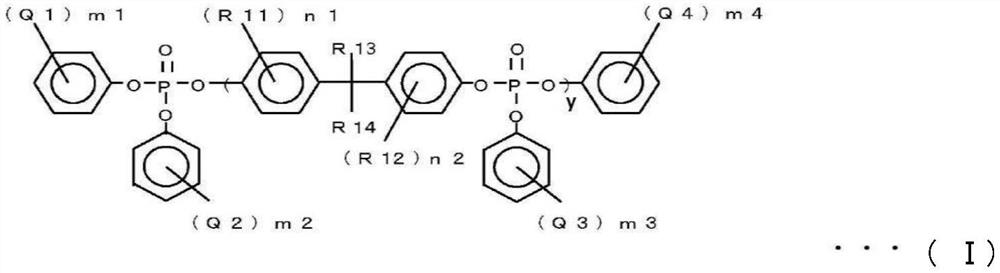

Resin composition, connection structure for solar power generation module, and junction box for solar power generation module

A resin composition and resin technology, which can be used in photovoltaic power generation, photovoltaic modules, electrical components, etc., can solve the problems of insufficient oil resistance, cracks, cracks, etc. of polyphenylene ether-based resin compositions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6、 comparative example 1~11

[0180] The components (a) to (d) and other flame retardants were supplied to the twin-screw extruder in the compositions shown in Tables 1 and 2, and the extrusion temperature was 300 to 320°C, the screw rotation speed was 300 rpm, and the discharge rate was 15 kg / Melt-kneading was performed under conditions of 1 hour to obtain pellets of the resin composition. The twin-screw extruder is set as follows: the number of barrels is 12, and in the direction of flow of the raw material, the upstream supply port is installed in the first barrel, the liquid feeding pump is installed in the seventh barrel, and the The 5th barrel and the 11th barrel are provided with a vacuum exhaust port.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com