Low-fiber-content high-filler-content sealing pad

A technology for sealing pads and inorganic fillers, applied in fiber raw material processing, non-polymer organic compound addition, synthetic cellulose/non-cellulose material pulp/paper, etc., can solve non-asbestos-free materials, breaking or damage, Problems such as the use of too many fibers, to achieve the effect of good liquid resistance, simple formula, and cheap raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

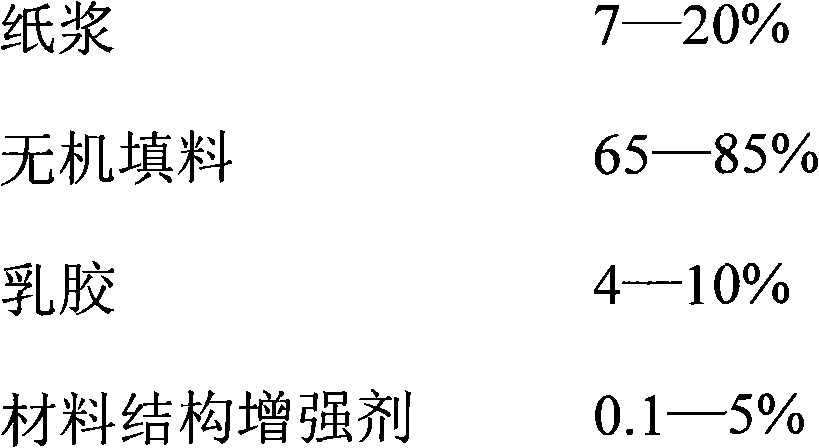

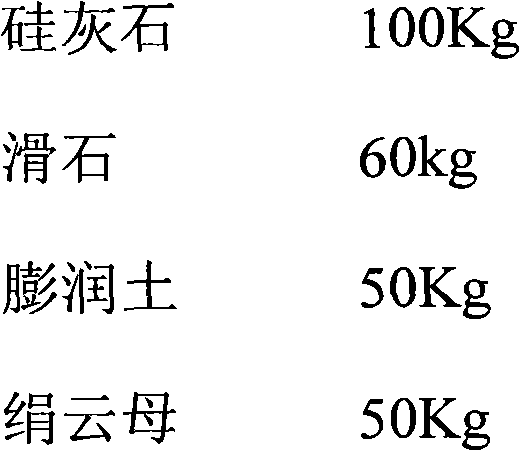

[0028] Example 1: Weigh separately

[0029]

[0030] Add 1000Kg of 3.2% consistency pulp suspension, then add a part of the slurry pre-milled with 6Kg of carbon black, 1.2Kg of zinc oxide, 1.2Kg of sulfur, 0.8Kg of accelerator TMTD, 0.4Kg of antioxidant D, and stir well. , While stirring, add 45Kg of latex with 40% solid content; add 15Kg of titanate, stir and mix, and dilute with water to make a slurry with a concentration of 2.5%, which is copied by a paper machine, dehydrated, dried, and calendered and cured at 130°C. Made into low-fiber high-filling gasket board.

Embodiment 2

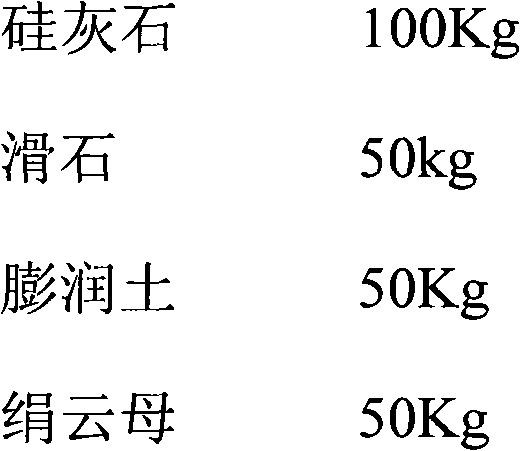

[0031] Example 2: Weigh separately

[0032]

[0033] Add 1400Kg of 3.2% concentration pulp suspension, then add 4Kg of carbon black, 1.2Kg of zinc oxide, 1.2Kg of sulfur, 0.8Kg of accelerator TMTD, 0.4Kg of anti-aging agent D, and add a portion of the slurry pre-milled. , While stirring, add 35Kg of latex with 40% solid content; add 12Kg of titanate, stir and mix, and dilute with water to make a slurry with a concentration of 2.5%, which is copied by a paper machine, dehydrated, dried, and calendered and cured at 130°C. Made into low-fiber high-filling gasket board

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com