Manufacturing process of composite spunlace non-woven fabric

A technology of spunlace non-woven fabric and production process, which is applied in non-woven fabrics, textiles and papermaking, and removal of liquid/gas/vapor by centrifugal force, etc., which can solve the problem that non-woven fabrics have poor water absorption and cannot heat blood autonomously. Circulation, less advantages and other problems, to achieve the effect of promoting blood microcirculation, excellent antistatic effect, and reducing skin damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

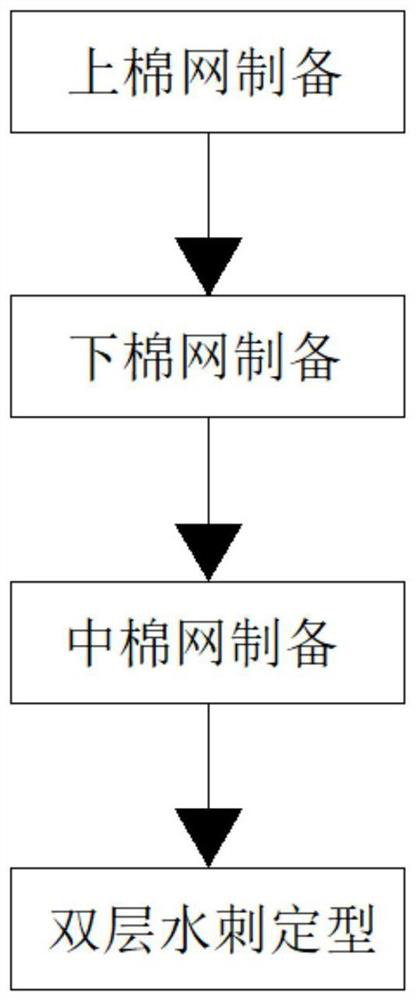

[0022] see figure 1 , the present invention provides a technical scheme: a manufacturing process of a composite spunlace non-woven fabric, comprising the following steps:

[0023] Step 1: Blend wood fiber, graphene fiber and graphite fiber with fiber blending equipment. After fiber blending is completed, the fiber is immersed in an antistatic liquid, and the nano water-absorbing particles are put into the antistatic liquid, and the fibers are adsorbed. Antistatic liquid and nano water-absorbing particles are then put into the cotton opener for opening after centrifugal drying, and sent to the cotton box, and then sent to the carding machine for carding after the cotton is discharged;

[0024] Step 2: Blend the super-absorbent fiber and Tentea fiber with fiber blending equipment. After the fiber blending is completed, the fiber is immersed in the antistatic liquid, and the nano-absorbent particles are put into the antistatic liquid. The electrostatic liquid and the nano water-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com