Temporary construction trestle suitable for mucky area and construction method

A muddy, trestle technology, applied to temporary construction trestles and construction fields, can solve the problems of long time consumption, high engineering cost, and many materials, and achieve the effects of reduced construction difficulty, less water environmental pollution, and easy transportation and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

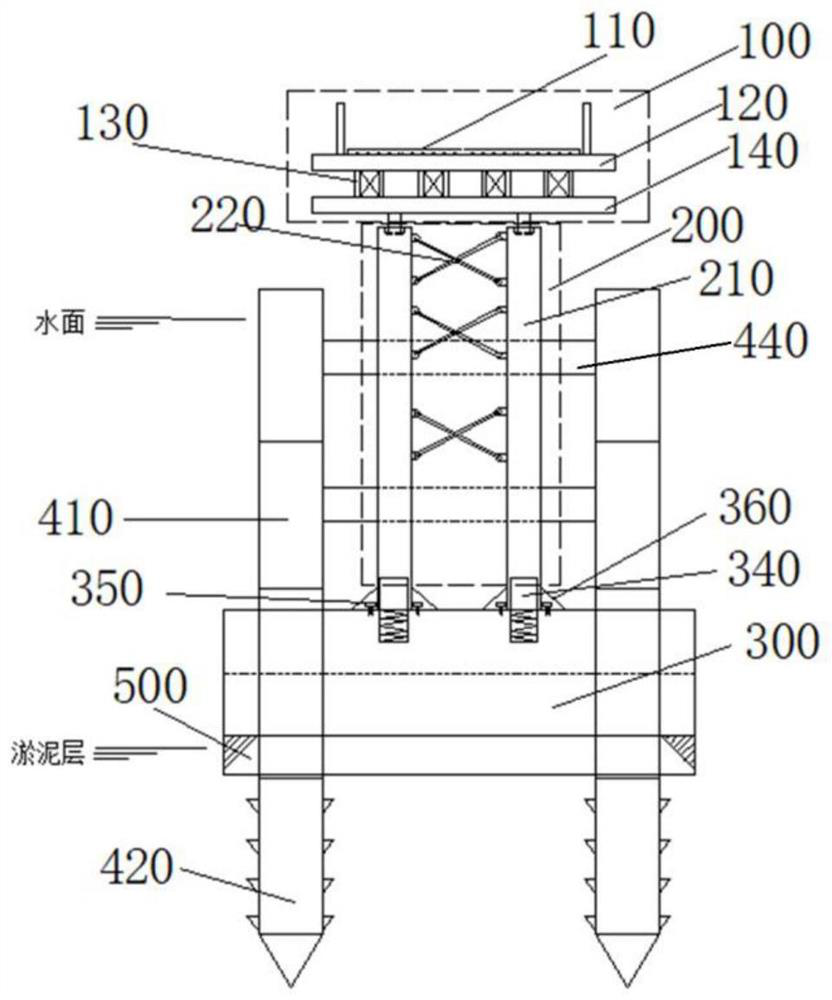

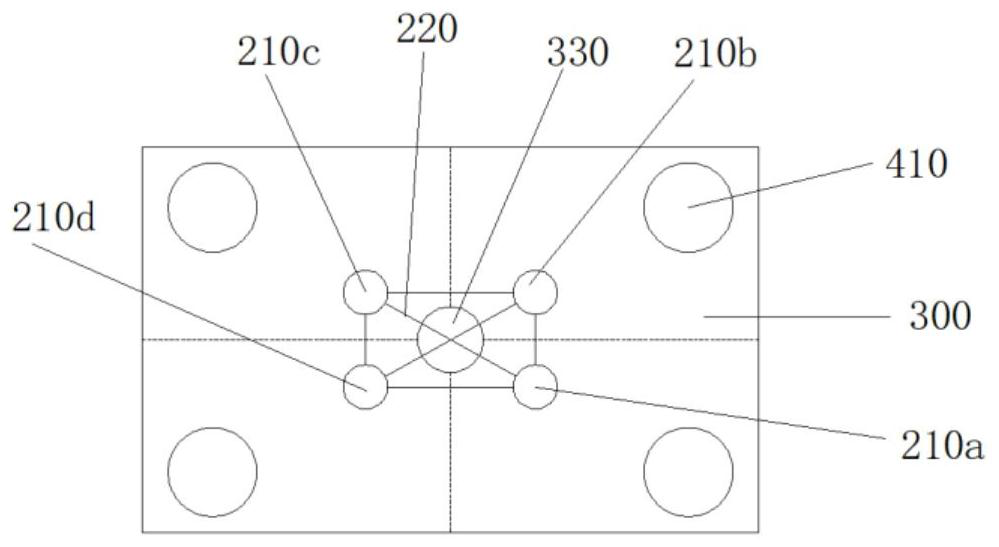

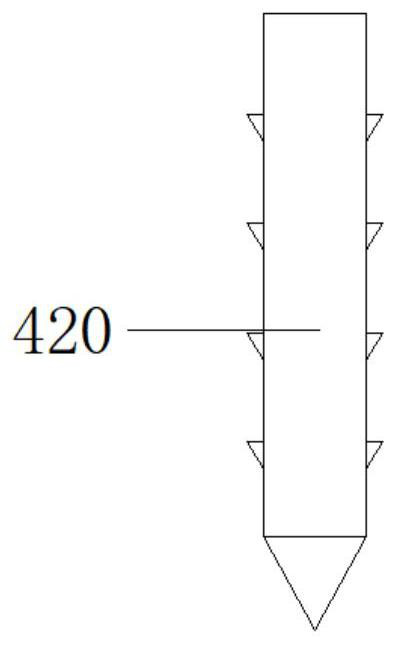

[0031] see Figures 1 to 7 , the temporary construction trestle in this embodiment mainly includes a bridge deck upper structure 100 and a lower structure, the bridge deck upper structure 100 includes a bridge deck structure 110 and a load-bearing upper structure for the bridge deck structure 110, and the upper structure includes an upper cushion beam 120, a shell The thunder beam 130 , the lower cushion beam 140 , and the bridge deck structure 110 are laid on the upper cushion beam 120 , and several Bailey beams 130 are fixedly installed between the upper cushion beam 120 and the lower cushion beam 140 in a laterally spaced manner. In this embodiment, the Bailey beams are first assembled in advance, and each Bailey beam is formed by connecting a plurality of Bailey sheets and fixed in series through Bailey pins. The assembled Bailey beams are transported to the construction pier and fixedly installed on the The preset position between the upper and lower pad beams. Bailey be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com