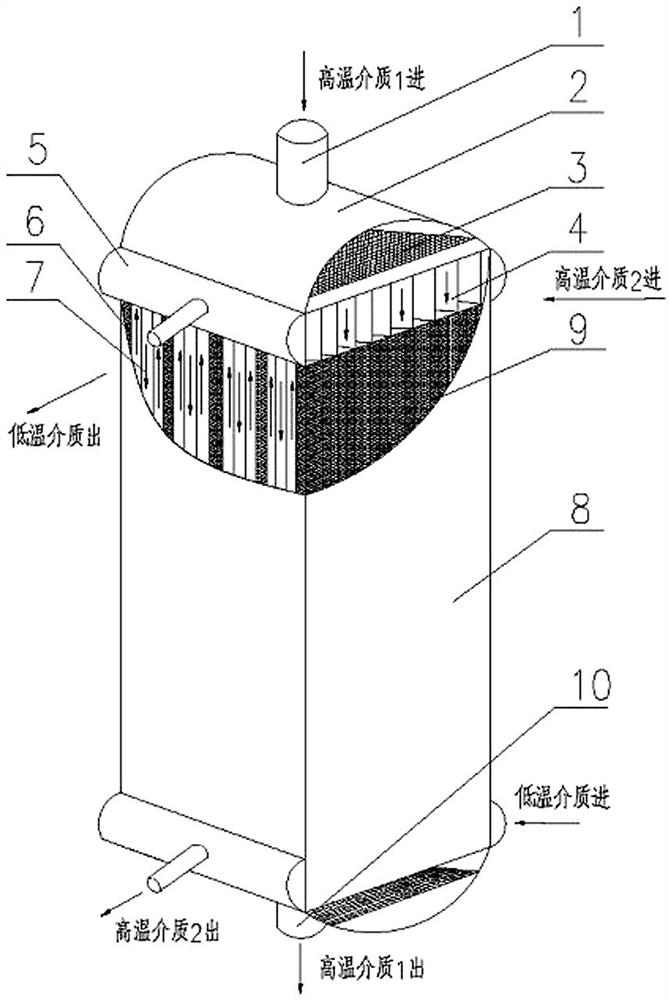

Plate-fin heat exchanger with built-in catalyst

A technology of plate-fin heat exchanger and catalyst, which is applied in the direction of indirect heat exchanger, heat exchanger type, heat exchanger shell, etc., which can solve the problems of cooling capacity loss, increasing the volume of cold box, increasing equipment investment cost, etc. , to achieve the effect of reducing cooling loss, reducing occupied space, and reducing equipment investment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

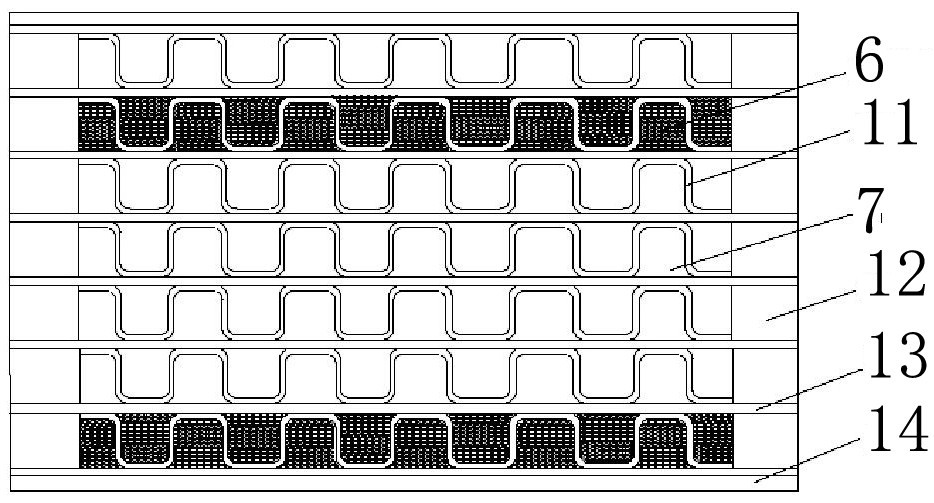

[0036] The difference between the second embodiment and the above-mentioned embodiment is only in the corresponding number of cold and hot medium streams, the position of the medium entering and leaving the heat exchanger, the position of the wire mesh head and the wire mesh head, the opening type of the guide vane and the exchange rate. Types of hot aisle fillers.

[0037] like Figure 4 As shown, in this embodiment, the heat exchange channel filler is an adsorbent.

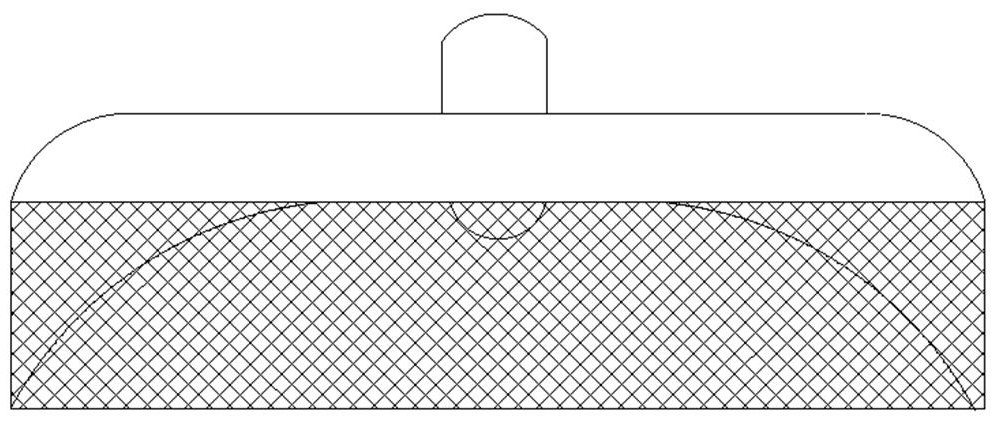

[0038] The impurity-containing high temperature medium 2 is taken over from the top side and enters the head with wire mesh, and then enters the heat exchange channel filled with adsorbent. The high temperature medium 2 exchanges heat with the low temperature medium 1 to cool down, and at the same time, the impurities in it are removed by the adsorbent in the heat exchange channel, and the purified high temperature medium 2 flows out from the bottom with a wire mesh head and an outlet pipe. The high-temperatur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com