Intelligent thickness detector for glass production and detection method

A technology for thickness detection and glass, which is applied in glass production, instruments, measuring devices, etc., can solve the problems of inconvenient arc glass detection and achieve the effect of convenient thickness measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

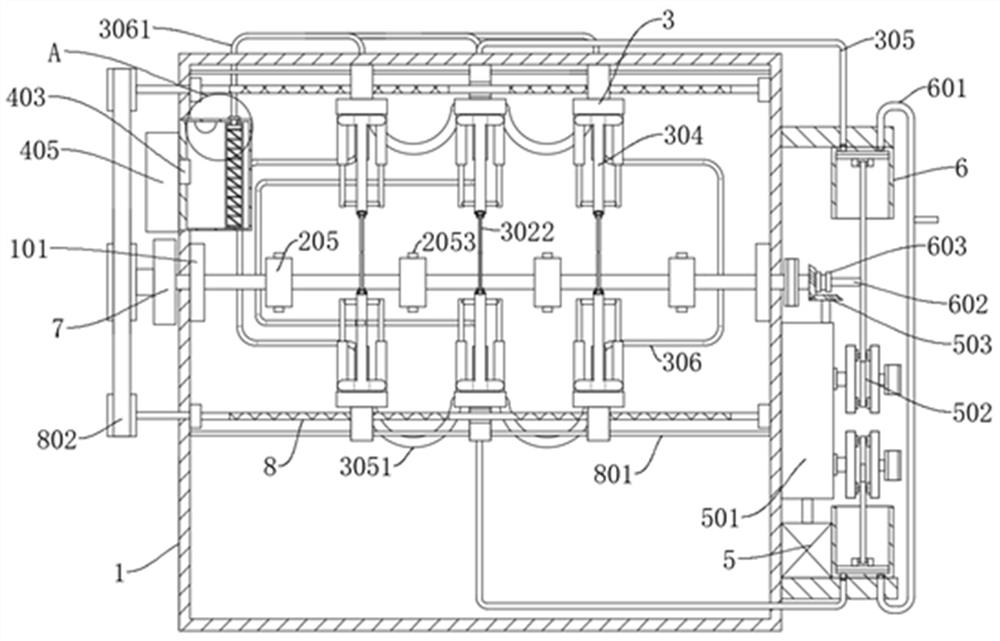

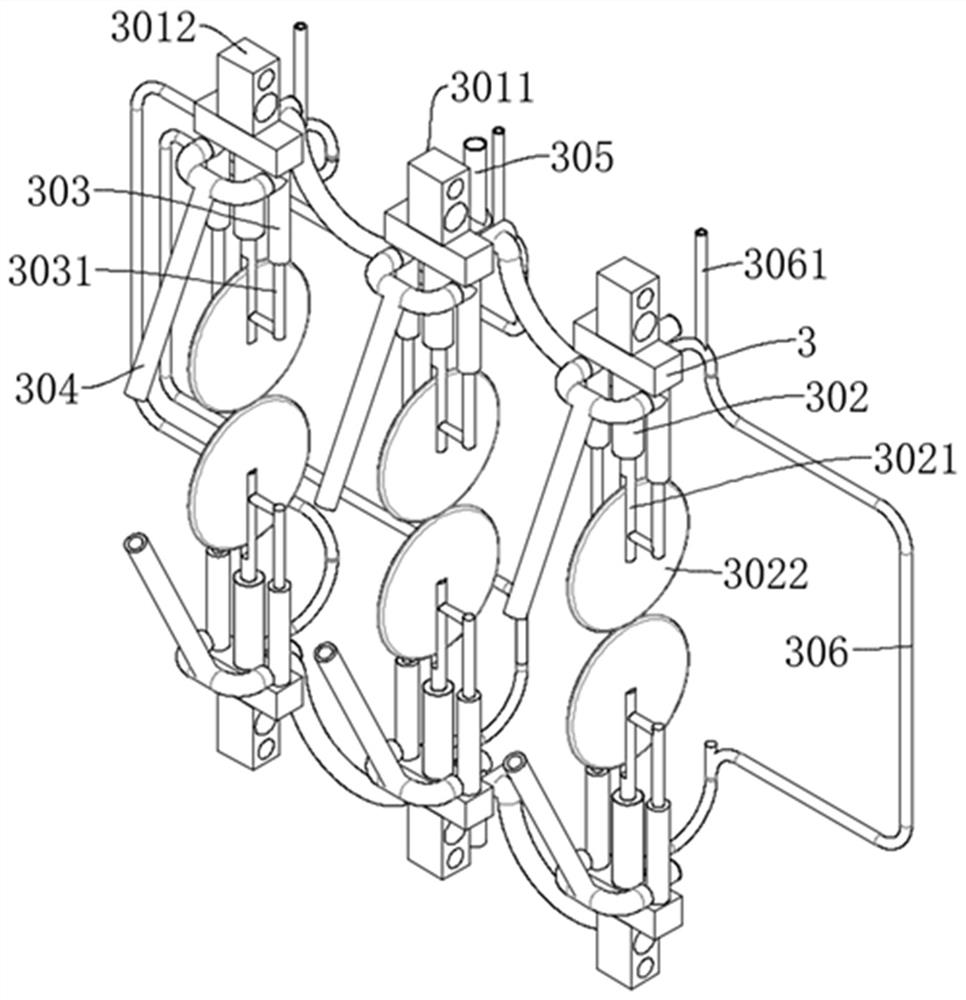

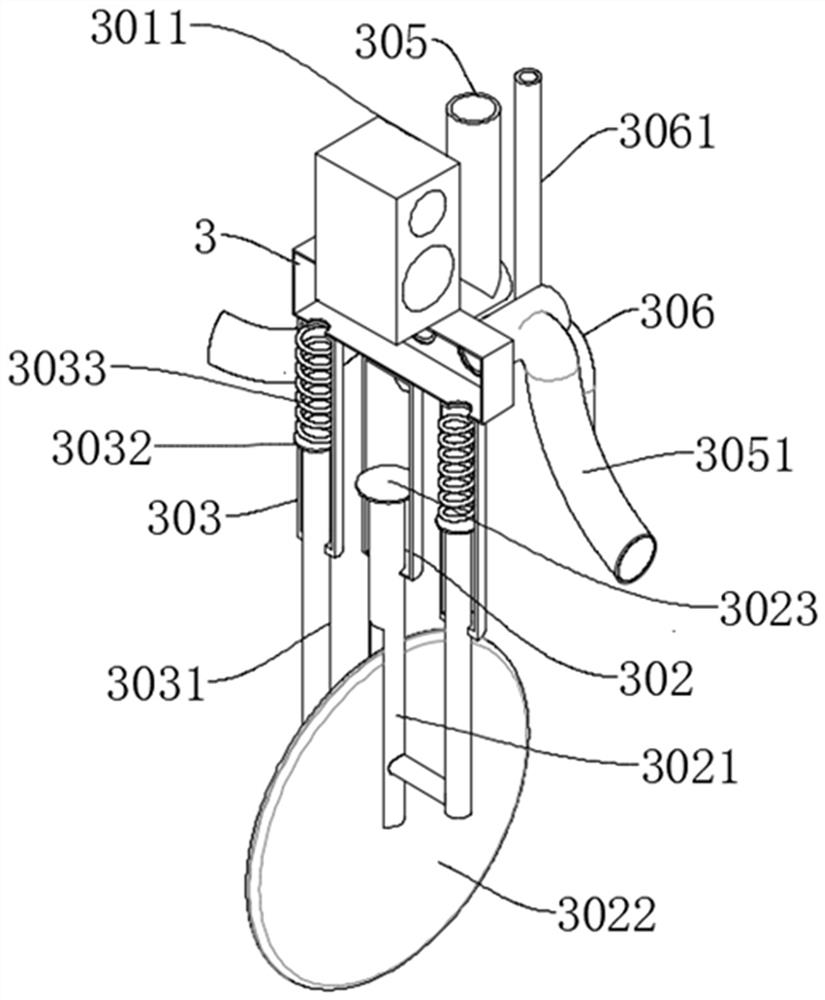

[0034] Example 1: refer to Figure 1-Figure 5 , an intelligent thickness detector for glass production, including a first installation box 1, and also includes: a conveying mechanism arranged in the first installation box 1 for transporting the glass; The first measurement mechanism in the first installation box 1 and the second measurement mechanism in the first installation box 1 through the second connecting block 3012, both the first measurement mechanism and the second measurement mechanism include the installation box 3, any adjacent The two installation boxes 3 are connected through the second air pipe 3051, the bottom of the installation box 3 is fixedly connected with the first sleeve 302, the first sleeve 302 is slidably connected with the first sliding rod 3021, and the first sliding rod 3021 is located in the first sleeve 302. One end of a sleeve 302 is fixedly connected with a first piston plate 3023, and one end of the first sliding rod 3021 away from the first p...

Embodiment 2

[0043] Embodiment 2, refer to figure 1 , an intelligent thickness detector for glass production, which is basically the same as the first embodiment, and further is that the first installation box 1 is rotatably connected with a double-ended reciprocating screw 8, and the second connecting block 3012 is connected to the double-ended reciprocating screw. The rod 8 is threadedly connected, the double-ended reciprocating screw 8 penetrates the first connecting block 3011, the first installation box 1 is fixedly connected with a positioning rod 801, and the positioning rod 801 penetrates the first connecting block 3011 and the second connecting block 3012, the installation shaft 2 One end away from the bevel gear set 503 is provided with a ratchet mechanism 7 , and the ratchet mechanism 7 is synchronously connected with the double-ended reciprocating screw 8 through the sprocket set 802 .

[0044] The installation box 3 is installed with an electric air relief valve, which opens t...

Embodiment 3

[0045] Embodiment 3: refer to Figure 1-Figure 5 , the same as the second embodiment, the present invention can also be used to measure the thickness of arc-shaped plates and flat plates made of other materials, and can measure the thickness of plates with signals such as isolating sensing signals and isolating light waves.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com