Ultra-thin silicon PIN high energy particle detector based on bonding substrate and manufacturing method thereof

A high-energy particle and detector technology, applied in semiconductor devices, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problems of increased corrosion time, increased leakage current, uncontrollable detector thickness, etc., to reduce detection The effect of detector leakage current, detector thickness determination, and detector thickness controllable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

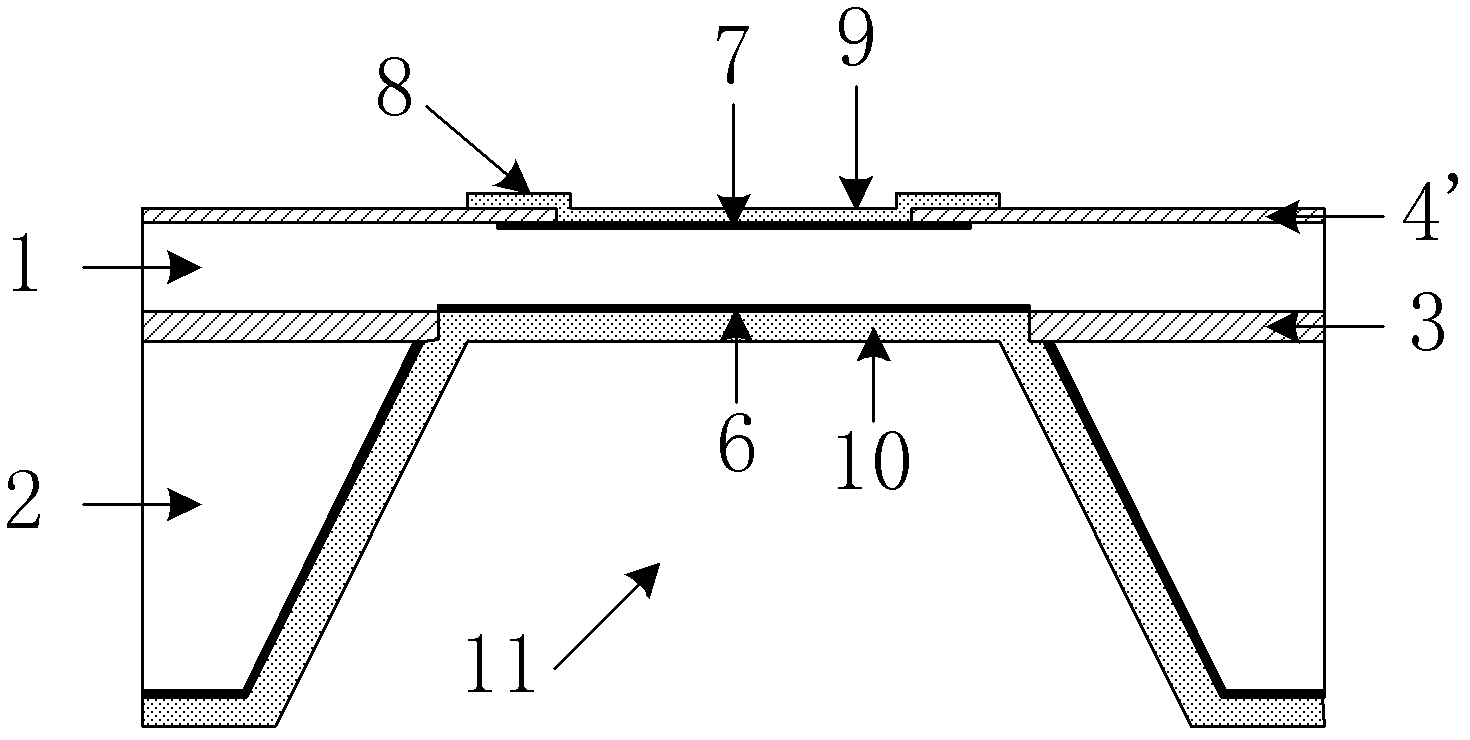

[0052] The bonded substrate ultra-thin silicon PIN high-energy particle detector and its preparation method of the present invention will be further described in detail below in conjunction with the best examples shown in the accompanying drawings.

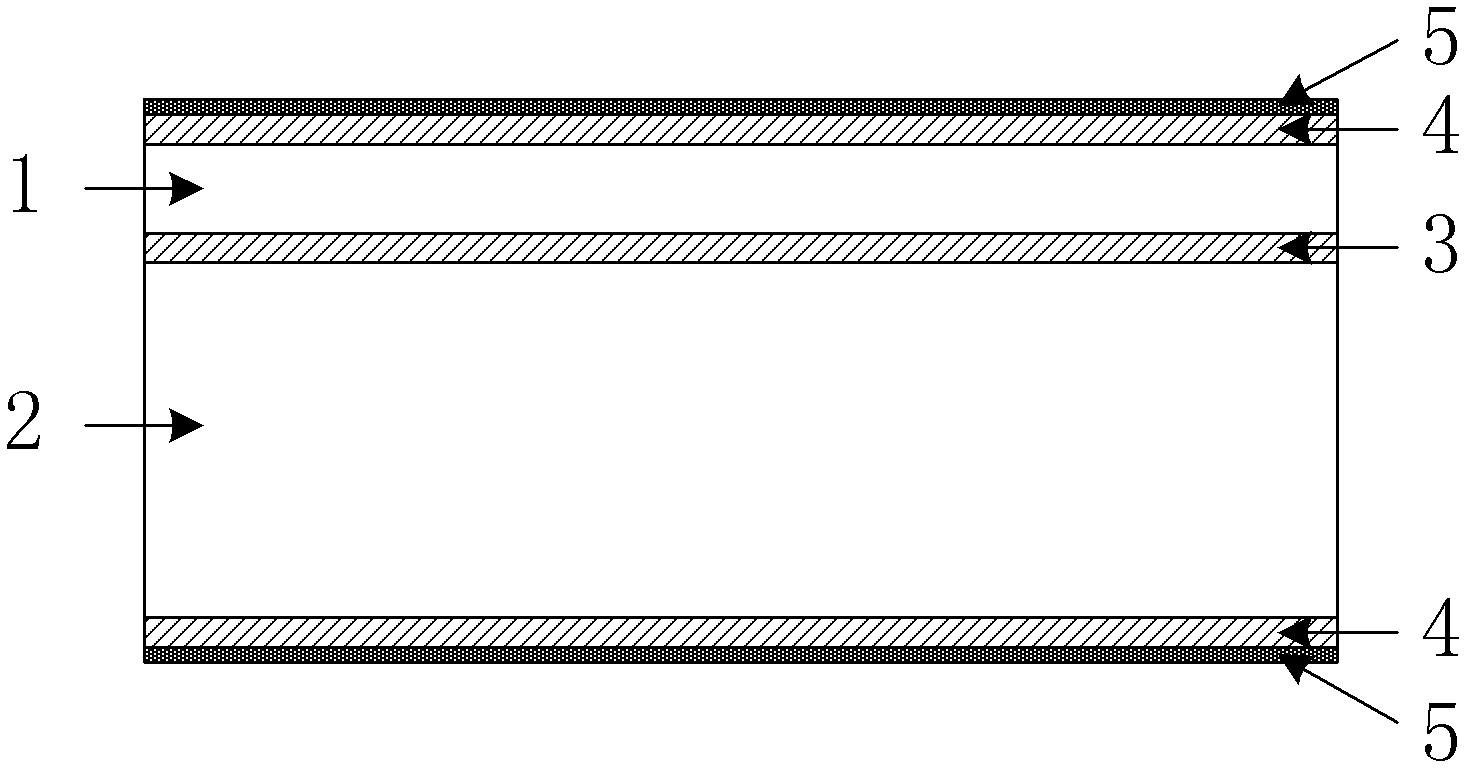

[0053] Such as figure 1 As shown, the ultra-thin silicon PIN high-energy particle detector structure based on the bonded substrate includes: a bonded silicon substrate composed of a device layer silicon chip 1 and a supporting layer silicon chip 2, wherein the device layer silicon chip 1 is a (111) crystal Oriented N-type silicon with a resistivity greater than 4000 ohm·cm and a thickness of 100 μm; the supporting layer silicon wafer 2 is (100) oriented N-type silicon with a resistivity of 2-4 ohm·cm and a thickness of 400 μm.

[0054] The front side of the device layer silicon wafer 1 has a boron-doped P + Region 7, to form PN junction, has thin aluminum layer 9 to cover on it, and thin aluminum layer 9 has field plate structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com