CPU-GPU (Central Processing Unit-Graphics Processing Unit) collaborative additive manufacturing parallel scanning line filling method

A technology of additive manufacturing and filling method, applied in the field of additive manufacturing, can solve problems such as unsatisfactory industrial production and low model processing efficiency, and achieve the effects of improving additive manufacturing efficiency, reducing calculation time, and accelerating calculation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

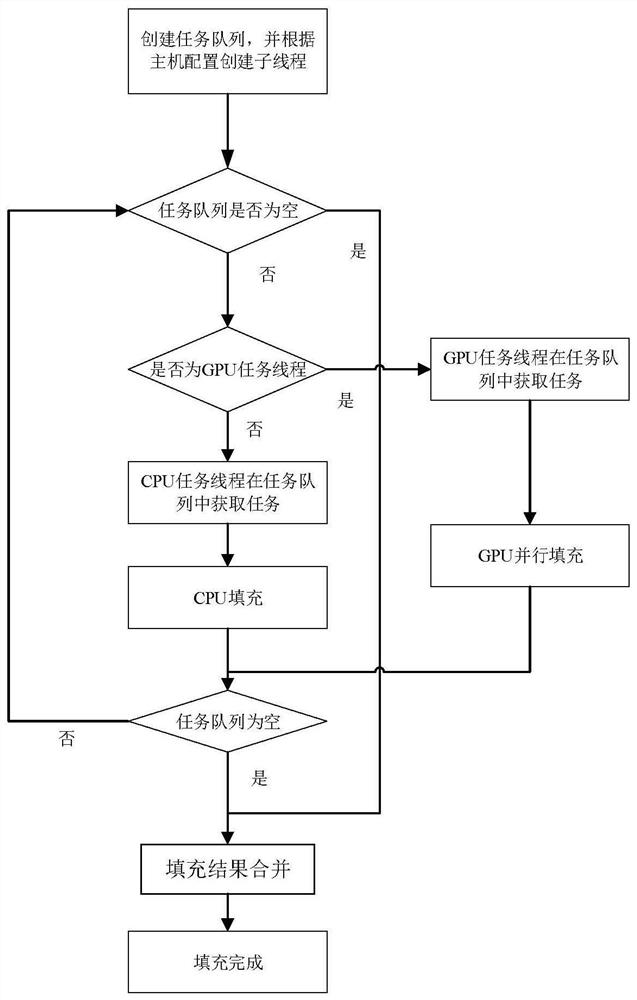

[0062] The invention provides a CPU-GPU coordinated additive manufacturing parallel filling method, which adopts the method of parallelizing the algorithm, utilizes the powerful parallel computing capability of the GPU, and combines the super multi-task coordination and comprehensive scheduling capability of the multi-core CPU. The scan line filling algorithm is improved, making full use of the computing resources of the hardware platform, and optimizing and accelerating the most time-consuming intersection sorting calculation process through the C++ multi-threading library, CUDA library, etc.

[0063] The concrete steps of the present invention are:

[0064] Step 1. Data preprocessing

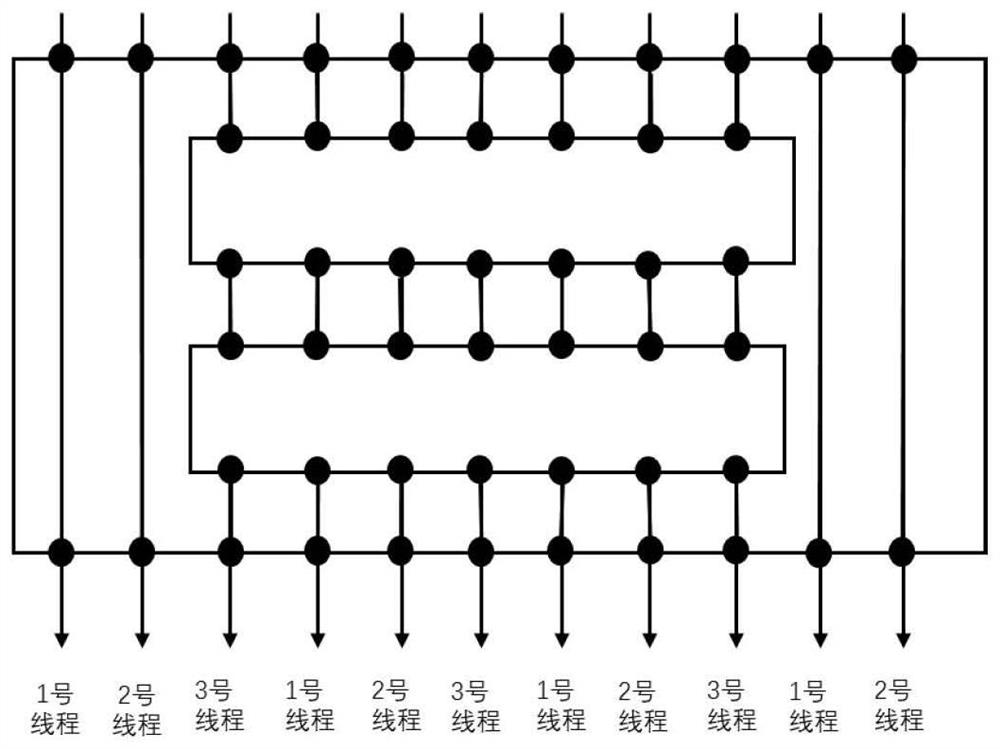

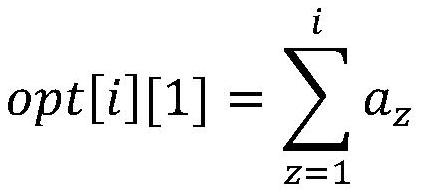

[0065] After the 3D model of the part to be additively manufactured is layered, the 3D model is divided into several layers according to the height from low to high, the number of layers is set to Layers, and Layers is a positive integer. First of all, it is necessary to calculate the task am...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com