Liquid metal oxidation corrosion numerical simulation calculation method

A liquid metal, oxidation and corrosion technology, applied in CAD numerical modeling, design optimization/simulation, greenhouse gas reduction, etc., can solve the problem that the process is difficult to measure accurately, and achieve the effect of strong versatility of the method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

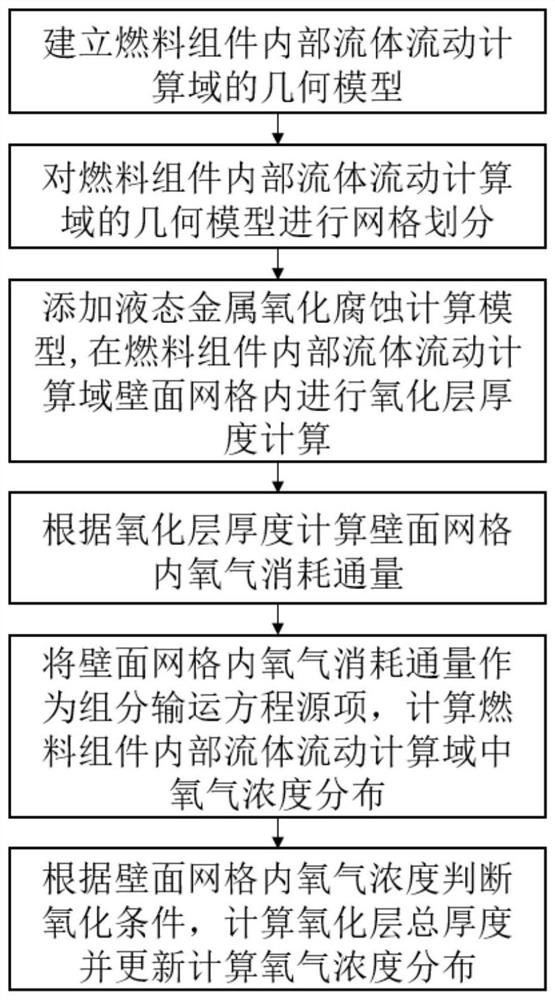

[0124] A method for numerical simulation calculation of liquid metal oxidation corrosion of the present invention comprises the following steps:

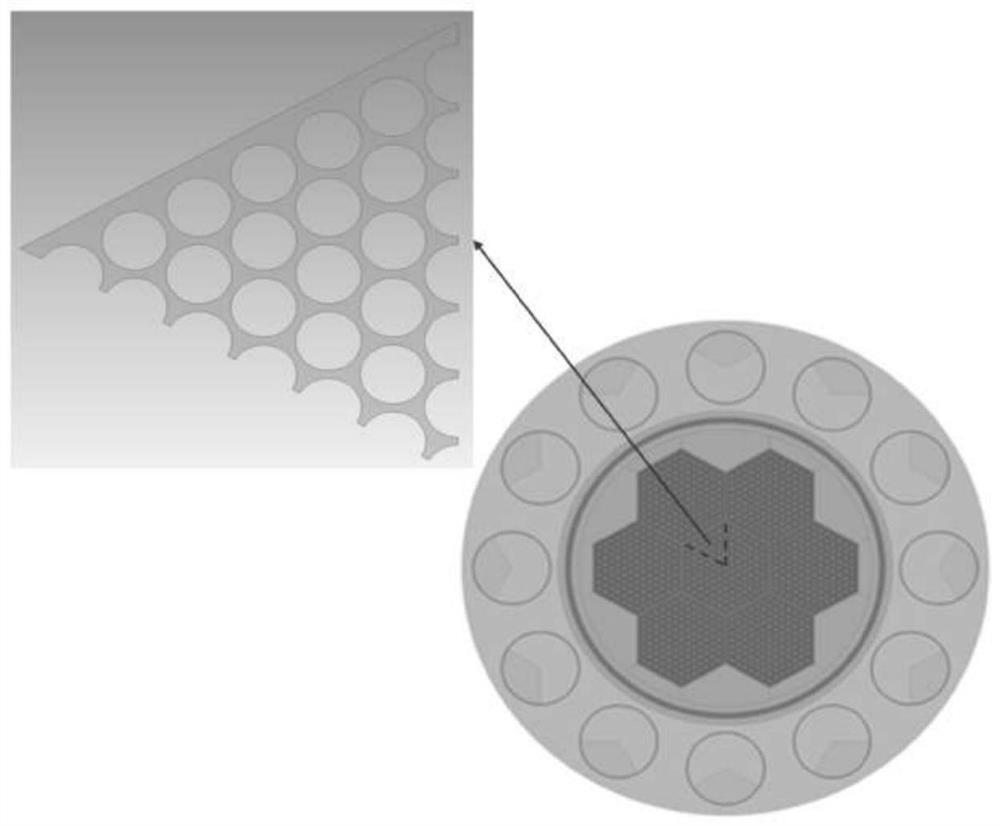

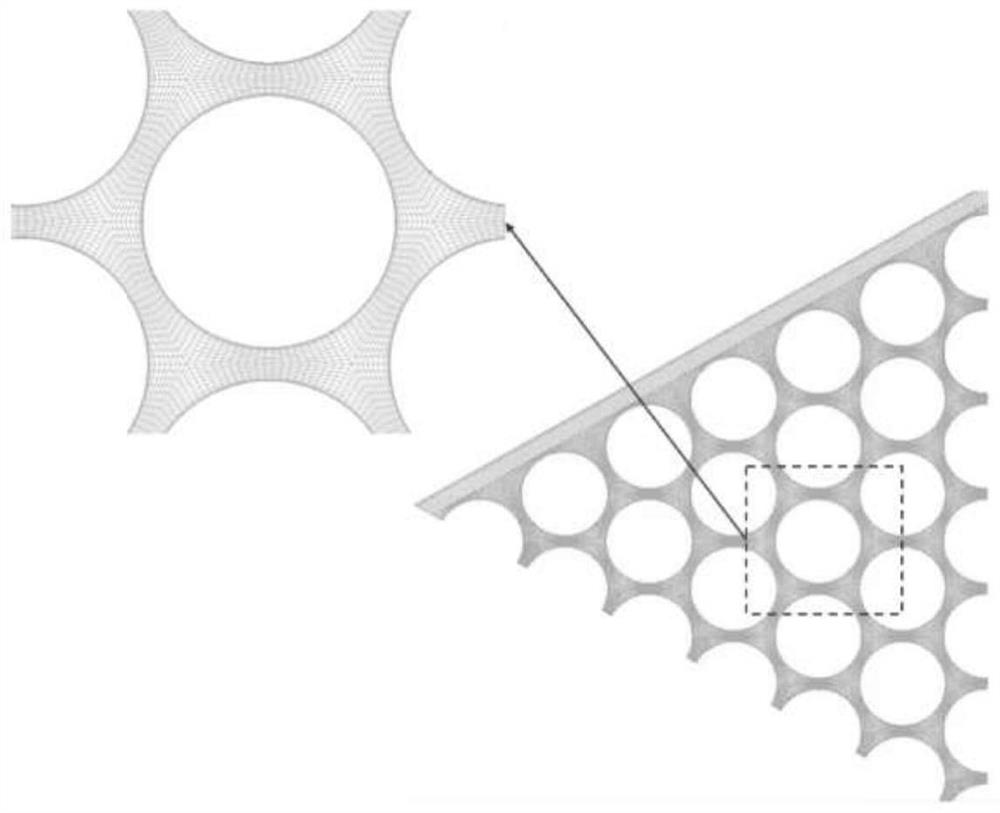

[0125] Step 1: In order to carry out the numerical simulation calculation of liquid metal oxidation corrosion, it is first necessary to establish a geometric model corresponding to the fluid flow calculation domain. For the flow of liquid metal in the fuel assembly, a geometric model of the computational domain of fluid flow in the fuel assembly is established, that is, the flow channel of liquid metal in the fuel assembly. The model includes a simplified calculation model of a symmetric fuel assembly and a computational domain for the internal flow of the fuel assembly. The specific steps are as follows:

[0126]Step 1-1: Use the geometric model establishment software to establish the computational domain model of the fuel assembly. Considering that the fuel assembly is a hexagonal symmetrical structure, in order to simplify the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com