Ethylene-based polymer composition with branched and process for producing same

A technology for polymers, compositions, applied in the field of ethylene-based polymer compositions with branching and processes for producing the compositions, capable of solving problems such as low molecular weight extractable fractions, low crystallinity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

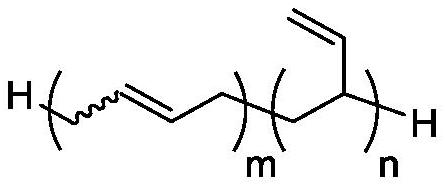

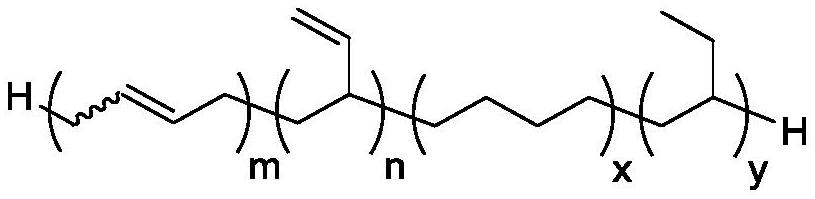

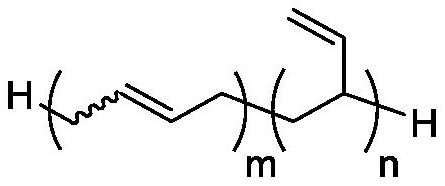

[0169] Polybutadiene (Additive A: Nisso PB B-1000, having structure I) was supplied by NipponSoda, Co.. The properties of this material are listed in Table 1 below.

[0170] Table 1

[0171]

[0172] 1 Provided by Soda Co., Ltd.

[0173] 2 Determined by GPC

[0174] 3 Calculated by dividing Mn by the Mw of the butadiene monomer (hydrocarbon molecule) and multiplying by the fractional number of terminal olefin groups in n and internal olefin groups in m. Example: Mn = 1200 g / mol, Avg n = (1200 g / mol) / (54.09 g / mol of butadiene monomer) = 22 repeat units * 0.85 (terminal / total olefins) = average 18.8 terminal vinyl groups / chain

[0175] Polymerization: Tubular Reactor

[0176] Comparative Sample 1

[0177] The polymerization is carried out in a tubular reactor with three reaction zones. In each reaction zone, pressurized water is used to cool and / or heat the reaction medium by circulating it through the jacket of the reactor. The inlet pressure was 222 MPa and the ...

example 1

[0180] The polymerization was carried out in a tubular reactor with three reaction zones, as discussed above for Comparative Sample 1 . All process conditions were the same as Comparative Sample (CS) 1 except Inventive Example 1, where Additive A was added to the first zone. Additional information can be found in Tables 2 and 3.

example 2

[0182] The polymerization was carried out in a tubular reactor with three reaction zones, as discussed above for Inventive Example 1 . All process conditions were the same as Inventive Example (IE) 1 except that additional additive A was fed to the first zone. Additional information can be found in Tables 2 and 3.

[0183] Table 2: Pressure and Temperature Conditions for Comparative and Inventive Examples

[0184]

[0185] Table 3: Polymer properties of the examples

[0186]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com