Exhaust blow-drying device

The technology of a casing and a vacuum cleaner is applied in the field of cleaning robots, which can solve the problems of inconvenient and fast drying of mops, and achieve the effect of improving the connection strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

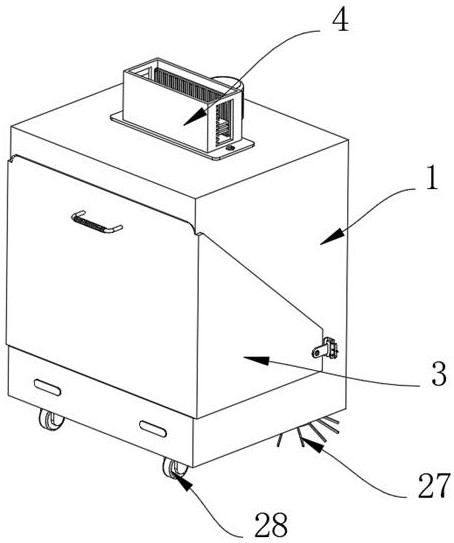

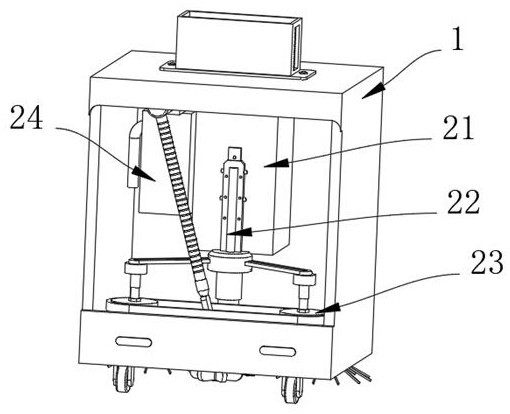

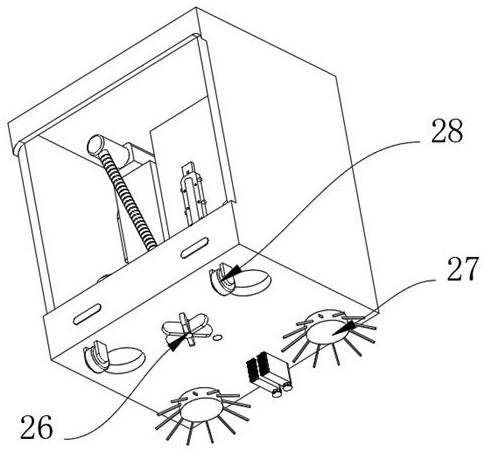

[0041] Example 1, as Figure 1-9 As shown, the present invention provides an exhaust drying device, comprising a casing 1 and a cleaning structure 2, the interior of the casing 1 is provided with a cleaning structure 2 for drying the mop, and the cleaning structure includes a cleaning structure for driving the mop head 23 to move The driver 22, the case 21 for regulating the driver 22, the vacuum box 24 for inhaling the sweeping dust, the connecting component 25 for connecting the vacuum box 24 and blowing the air in the vacuum box 24 to the tractor 23, With the sweeping head 26 of the cleaning tractor 23, the cleaning element 27 for cleaning the ground and the cleaning component 29 for cleaning the sweeping head 26 in time, one end of the casing 1 is provided with a limit structure 3, and the upper surface of the casing 1 is provided with a limit structure 3. A counterweight structure 4 is provided.

[0042] The specific settings and functions of the cleaning structure 2 , t...

Embodiment 2

[0047]Embodiment 2, on the basis of embodiment 1, as Figure 8 and Figure 9 As shown, the counterweight structure 4 includes a backing plate 41. The backing plate 41 is fixedly connected to the upper surface of the casing 1 by means of bolts. Hole 43, frame 42 A plurality of tooth blocks 44 are fixedly connected to one side of the inner wall of the rectangular hole 43, and the plurality of tooth blocks 44 are evenly distributed on one side of the inner wall of the rectangular hole 43. A counterweight 45 is used to increase the gravity of the casing 1 and improve the cleaning strength of the ground, so that the number of counterweights 45 can be increased or decreased according to the actual cleaning needs, thereby increasing the pressure of the casing 1 on the ground, and then Adjust the effect of the cleaning strength of the tractor 23 on the ground. One side of the frame 42 is slidably inserted with a pull rod 46, the two arms of the pull rod 46 are fixedly connected with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com