Wet spraying manipulator electric control system

An electronic control system and manipulator technology, applied in manipulators, comprehensive factory control, manufacturing tools, etc., can solve the problems of limiting work efficiency and convenience of use, inaccurate control, single function, etc., to achieve the effect of improving convenience.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

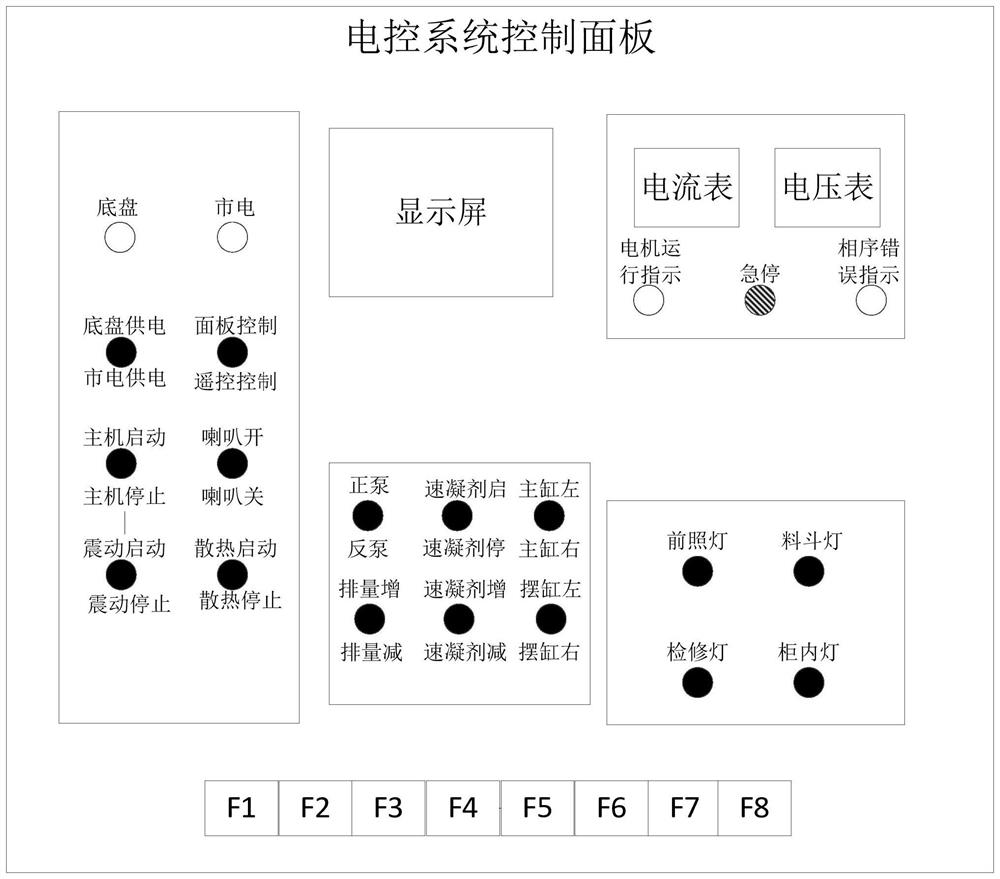

[0039] This embodiment provides an electronic control system for a wet spraying manipulator. The system includes a remote control and a control cabinet. The control cabinet includes a control panel and an internal circuit of the control cabinet. Meter, indicator light and control cabinet control switch, control cabinet control switch includes motor and lamp switch, displacement switch, positive and negative pump switch and remote control panel switch. Among them, the displacement switch includes an accelerator increase / decrease switch and a square volume increase / decrease switch.

[0040] The electronic control system of the wet spraying manipulator provided in this embodiment can not only control the running action of the wet spraying manipulator, but also adjust the amount of shotcrete and the dosage of the accelerator in real time, so that the accelerator is linked with the amount of spraying to achieve The best match required for shotcrete.

Embodiment 2

[0042] This embodiment further provides a specific implementation of the control panel of the control cabinet on the basis of the foregoing embodiment.

[0043] refer to figure 1 ,like figure 1 Shown is a schematic diagram of the control panel of the control cabinet of the electronic control system of the wet spraying manipulator provided in this embodiment.

[0044] The control panel of the control cabinet of the electronic control system of the wet spraying manipulator includes a display screen arranged in the center of the control panel. The display screen is a display screen with function buttons, including the main interface button, emergency interface button, unlock interface button, machine lock setting button, System monitoring button, parameter setting button and alarm query button.

[0045] There are two indicator lights and six button switches on the left part of the display screen. Among them, the two indicators are status indicators, located at the top, the left...

Embodiment 3

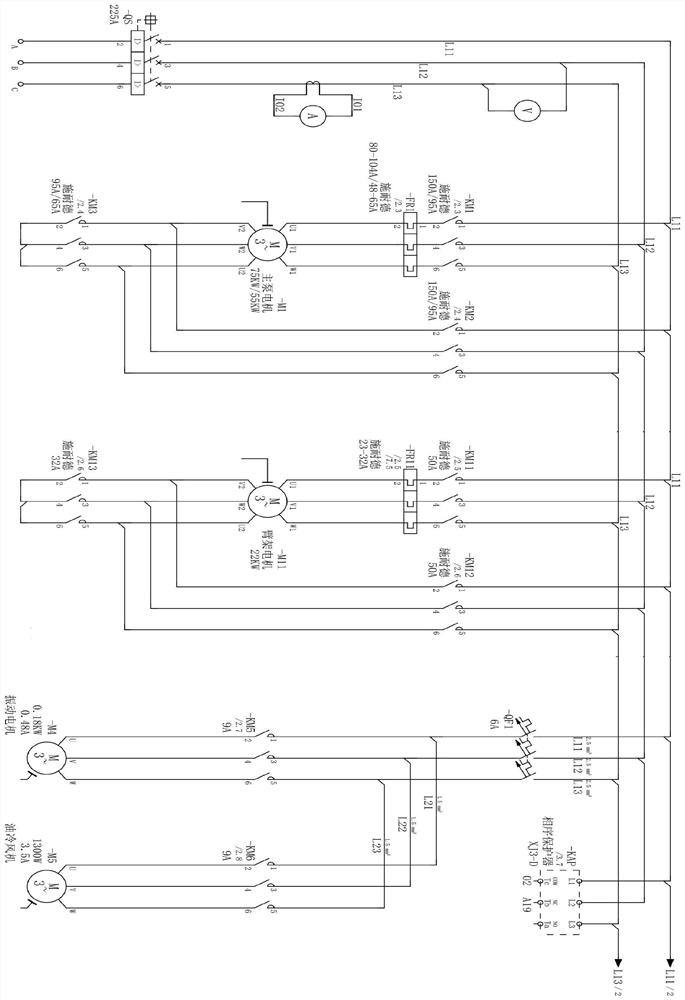

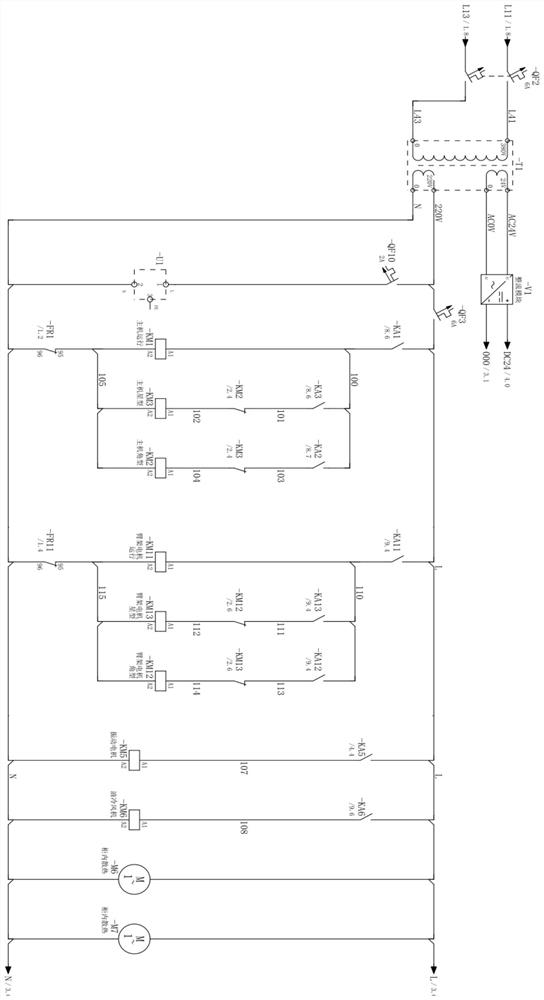

[0054] This embodiment further provides a specific implementation of the internal circuit of the control cabinet on the basis of the foregoing embodiment.

[0055]The internal circuit of the control cabinet includes a first main circuit, a second main circuit, a first control circuit and a second control circuit. refer to Figure 2-Figure 5 ,like figure 2 Shown is the schematic diagram of the first main circuit of the internal circuit of the control cabinet of the electronic control system of the wet spraying manipulator provided in this embodiment, as shown in image 3 Shown is a schematic diagram of the second main circuit of the internal circuit of the control cabinet of the electronic control system of the wet spraying manipulator provided in this embodiment, as shown in Figure 4 Shown is a schematic diagram of the first control loop of the internal circuit of the control cabinet of the electronic control system of the wet spraying manipulator provided in this embodime...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com