Combined box girder structure and construction method thereof

A beam structure and combination box technology, applied in bridges, bridge construction, bridge materials, etc., can solve the problems of cumbersome internal formwork erection and dismantling processes, low effective bearing capacity, limited spanning capacity, etc., and achieve rapid assembly construction. , The effect of reducing the weight of the structure and increasing the spanning capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

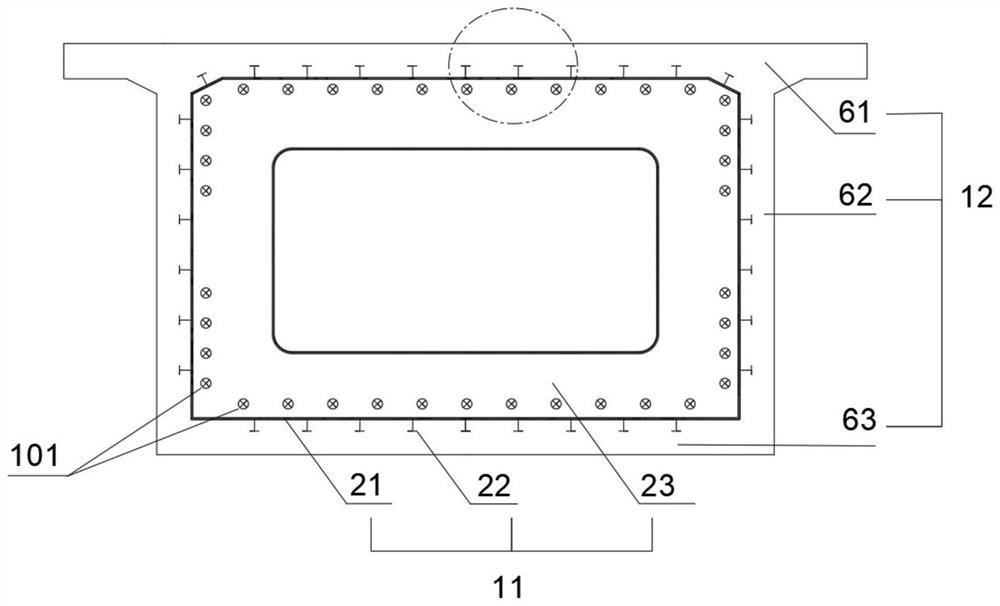

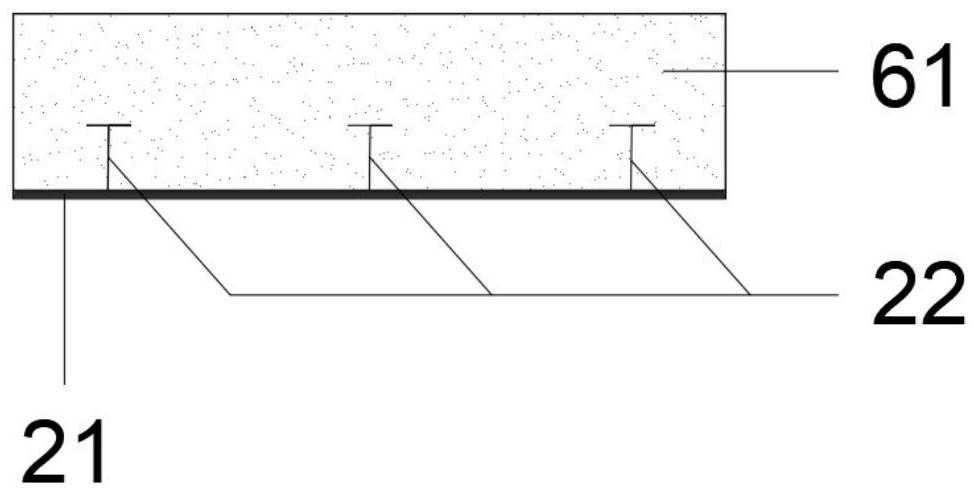

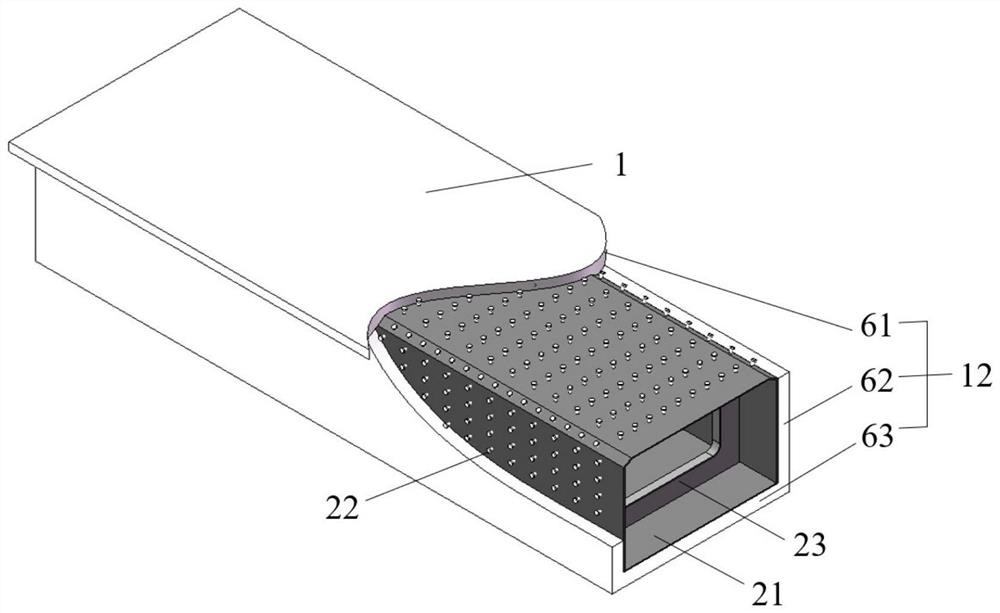

[0049] like Figure 1-Figure 5 As shown, the composite box girder structure 1 of this embodiment includes a box-shaped outer shell 12 and an inner core 11 . The inner core 11 includes a thin-walled steel shell 21 , a diaphragm 23 and a shear connector 22 , and the diaphragm 23 runs along the inner core 11 . The cross-sectional direction of the thin-walled steel shell 21 is fixed on the inner side of the thin-walled steel shell 21 , and the thin-walled steel shell 21 is fitted and fixed on the inside of the box-shaped shell 12 through the shear force connector 22 .

[0050] The thin-walled steel shell 21 is a box structure with a "mouth"-shaped cross-section, which is completely covered and fixed on the inner surface of the box-shaped shell 12; m.

[0051] The diaphragm 23 is a T-shaped steel plate, and there are a plurality of them along the longitudinal bridge direction, with a distance of 2m to 10m and a thickness of 0.008m to 0.015m. The diaphragm 23 is provided with exter...

Embodiment 2

[0062] like Figure 6-Figure 9 As shown, the composite box girder structure 1 of this embodiment includes a box-shaped outer shell 12 and an inner core 11 . The inner core 11 includes a thin-walled steel shell 21 , a diaphragm 23 and a shear connector 22 , and the diaphragm 23 runs along the inner core 11 . The cross-sectional direction of the thin-walled steel shell 21 is fixed on the inner side of the thin-walled steel shell 21 , and the thin-walled steel shell 21 is fitted and fixed on the inside of the box-shaped shell 12 through the shear force connector 22 .

[0063] The thin-walled steel shell 21 is a box structure with a "mouth"-shaped cross-section, which is completely covered and fixed on the inner surface of the box-shaped shell 12; m.

[0064] The diaphragm 23 is a T-shaped steel plate, and there are a plurality of them along the longitudinal bridge direction, with a distance of 2m to 10m and a thickness of 0.008m to 0.020m. The diaphragm 23 is provided with exter...

Embodiment 3

[0070] like Figure 10 and Figure 11 As shown, the composite box girder structure 1 of this embodiment includes a box-shaped outer shell 12 and an inner core 11 . The inner core 11 includes a thin-walled steel shell 21 , a diaphragm 23 and a shear connector 22 , and the diaphragm 23 runs along the inner core 11 . The cross-sectional direction of the thin-walled steel shell 21 is fixed on the inner side of the thin-walled steel shell 21 , and the thin-walled steel shell 21 is fitted and fixed on the inside of the box-shaped shell 12 through the shear force connector 22 .

[0071] The thin-walled steel shell 21 has a "冂"-shaped structure in cross section, which is completely covered and fixed on the inner surface of the UHPC bridge deck 61 and the UHPC web 62; the thin-walled steel shell 21 is made of weathering steel, and the thickness of the thin-walled steel shell 21 is 0.008m ~0.015m.

[0072] The diaphragm 23 is a T-shaped steel plate, and there are a plurality of them a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com