Embedded panel structure and manufacturing method thereof

A manufacturing method and embedded technology, applied in semiconductor/solid-state device manufacturing, data processing input/output process, instruments, etc., can solve problems such as excessive noise, high technical requirements, lower yield, etc., to reduce panel The effect of thickness, reducing pixel area and increasing aperture ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

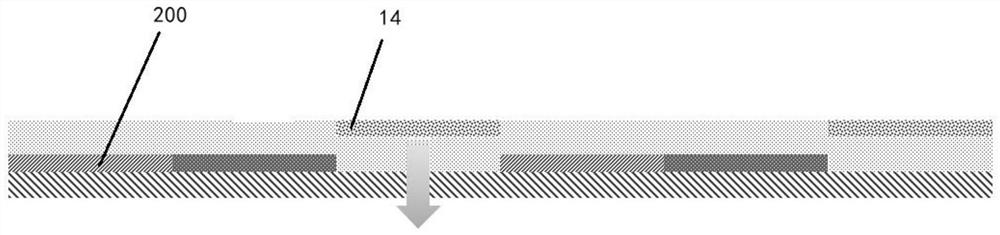

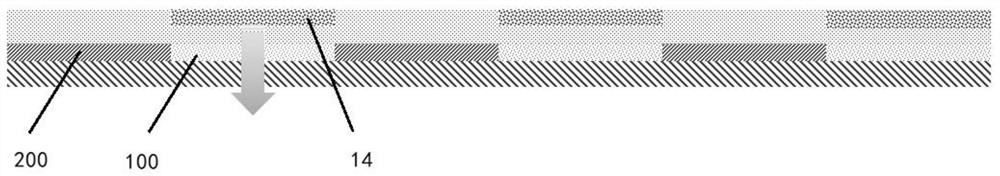

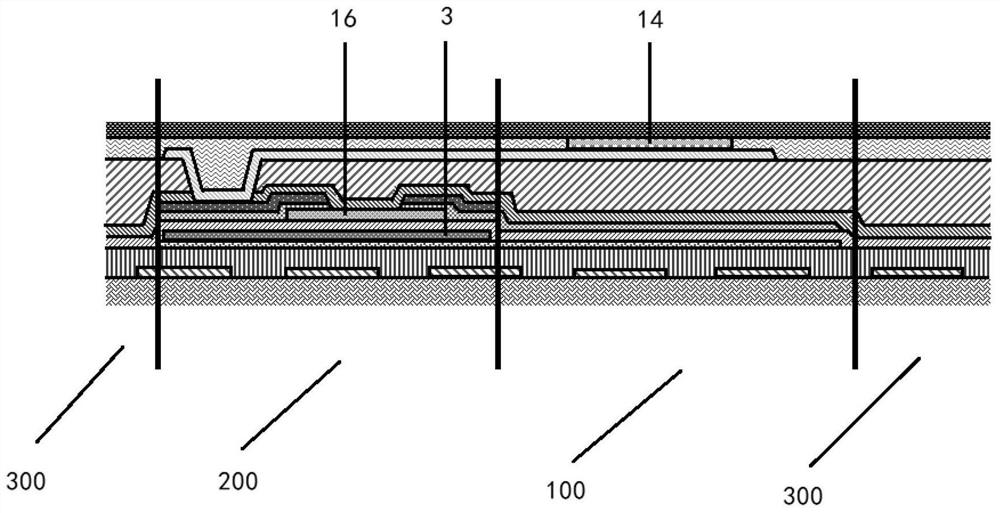

[0070] see Figure 1 to Figure 19 In this application, a method for manufacturing an embedded panel structure is provided, including the steps of: dividing the substrate 1 into a light-transmitting capacitor area 100, a TFT area 200, and a substrate area 300; please refer to Figure 17 to Figure 19 ,exist Figure 17 to Figure 19 The etching method of the gate metal layer 3 and the first light-transmitting conductive layer is listed in ; meanwhile, the manufacturing method of the second light-transmitting conductive layer and the source-drain metal layer is also the same, only the first light-transmitting conductive layer needs to be Layer is replaced by the second light-transmitting conductive layer, and the gate metal layer is repla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com