Vibration reduction power transmission tower system with composite vibration isolation base and cantilever tuning beam

A technology of transmission tower and cantilever beam, applied in the direction of tower, wind power generation, building type, etc., can solve problems such as overturning and multi-dimensional horizontal deformation difference, and achieve the effect of improving safety, low cost and strong implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] The specific embodiments are further explained below in conjunction with the accompanying drawings, and it should be understood that the following specific embodiments are only used to illustrate the present invention and not to limit the scope of the present invention. It should be noted that the drawings depict only certain salient features and are not necessarily drawn to scale and therefore should not be relied upon to scale.

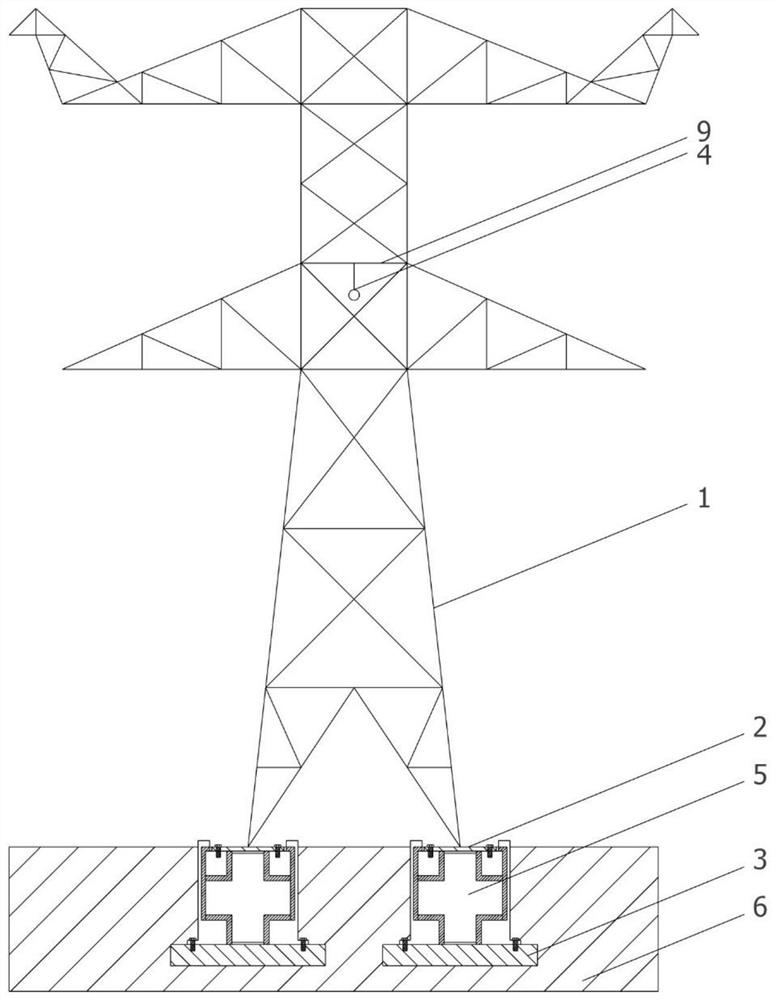

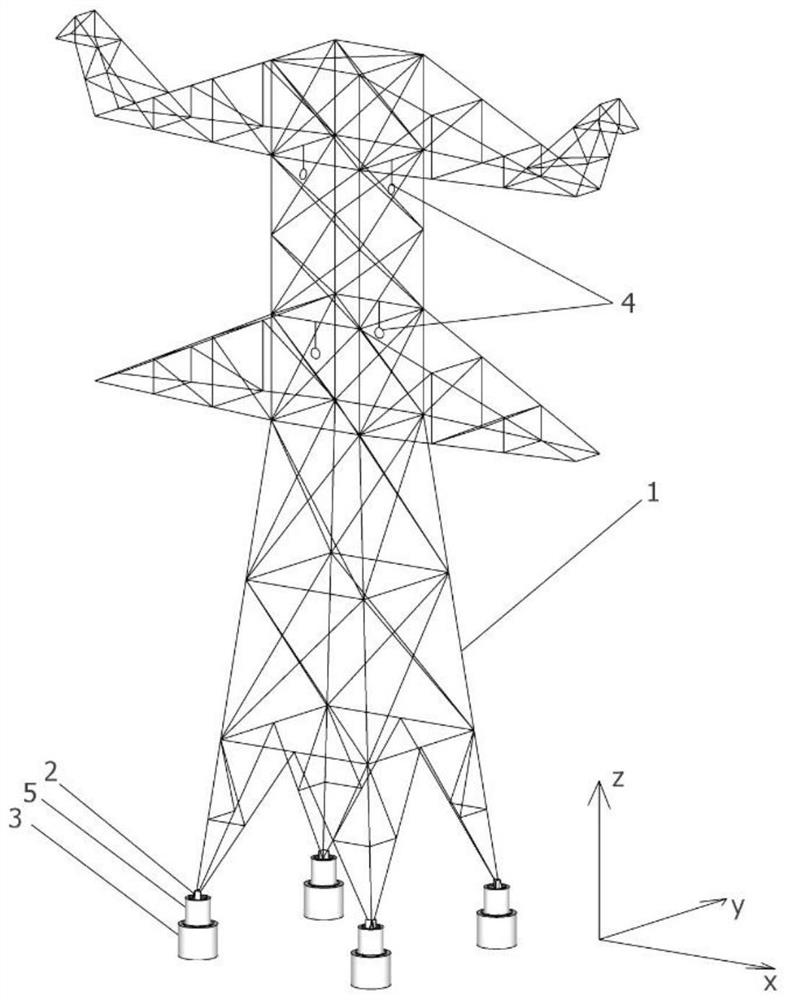

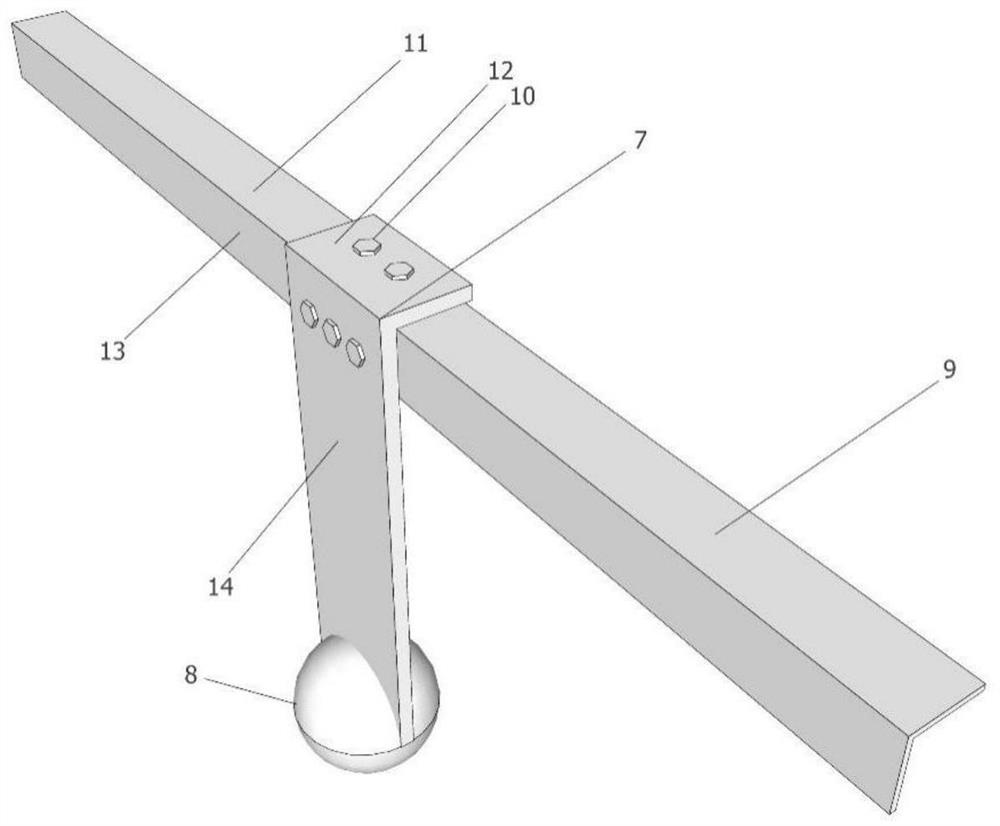

[0038] like figure 1 As shown, a vibration-absorbing transmission tower system with a composite vibration isolation base and a cantilever tuning beam includes a transmission tower body (1), a tower foot support (2), a concrete base (3), a cantilever tuning beam (4) and a composite Vibration isolation base (5), ground surface (6), L-shaped cantilever beam (7), spherical concentrated mass (8), transmission tower beam (9), bolts (10), upper bolts (15), upper metal plates ( 16), upper metal rubber layer (17), intermediate mass (18), lower metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com