Pipe jacking machine capable of being disassembled in pipeline

A pipe jacking machine and pipeline technology, which is applied in the direction of pipeline laying and maintenance, pipes/pipe joints/pipe fittings, mechanical equipment, etc. Simple, on-site assembly and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions of the present invention are further described below with reference to the accompanying drawings and through specific embodiments.

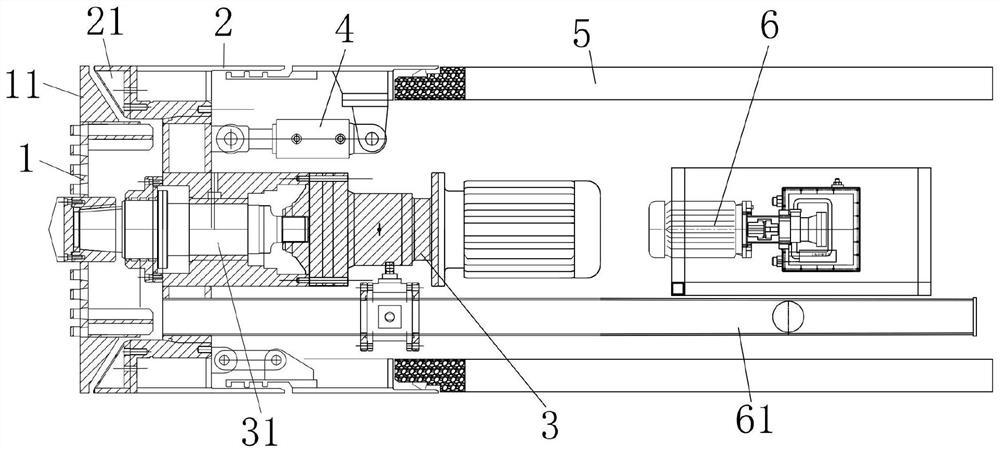

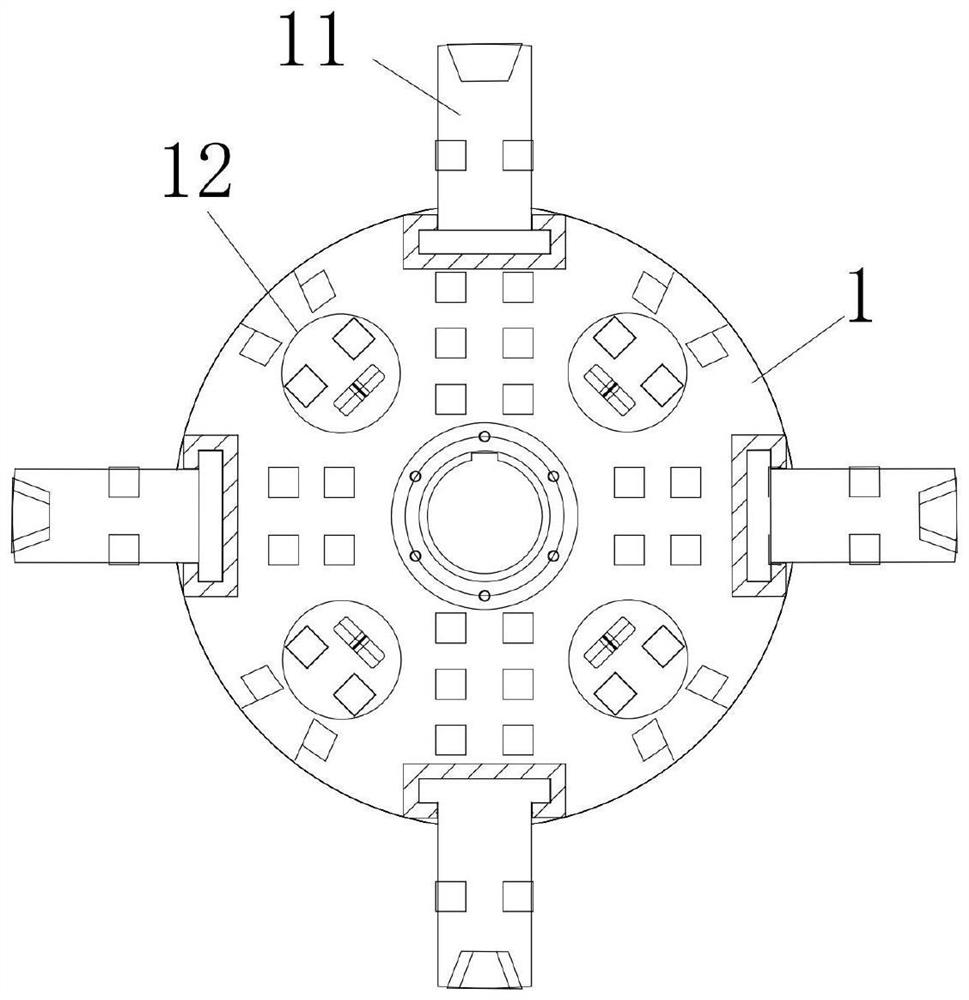

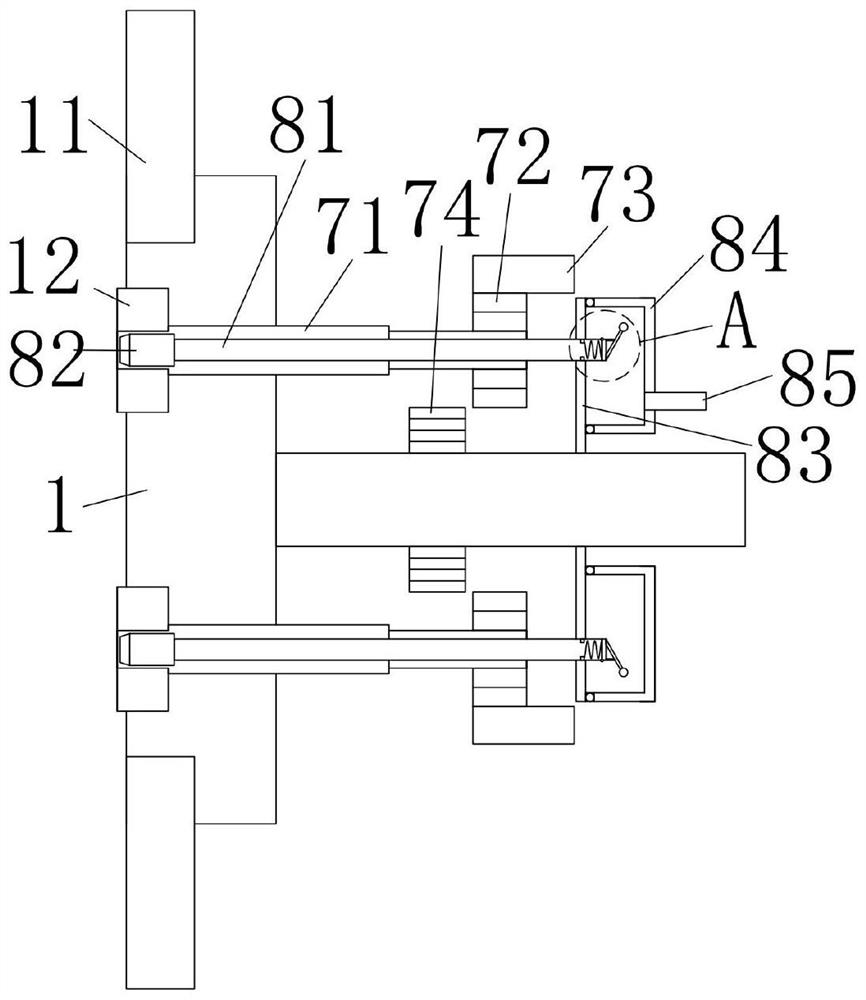

[0022] like Figure 1-4 As shown, the embodiment provides a pipe jacking machine that can be disassembled in a pipeline, comprising a main body (2), a core (3), a main cutter head (1) and a side cutter (11), and the main cutter head (1) ) is rotatably connected to one end of the fuselage (2), the movement (3) is fixed inside the fuselage (2), the power output end of the movement (3) is fixedly connected to the main cutter head (1), and two or more edge cutters (11) is evenly clamped on the side of the main cutter head (1).

[0023] During the pipe jacking operation, first install the side cutter (11) on each installation position on the side of the main cutter head (1), then place the machine body (2) in front of the ground to be excavated, and place the pipe (5) ) to the rear of the fuselage (2), start the moveme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com