Dust collector motor

A vacuum cleaner and motor shaft technology, which is applied in the direction of vacuum cleaners, electric components, electromechanical devices, etc., can solve the problems of inconvenient disassembly, maintenance and cleaning of vacuum cleaner motors, and low heat dissipation efficiency, so as to facilitate daily maintenance and cleaning operations, improve efficiency, and facilitate The effect of daily cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

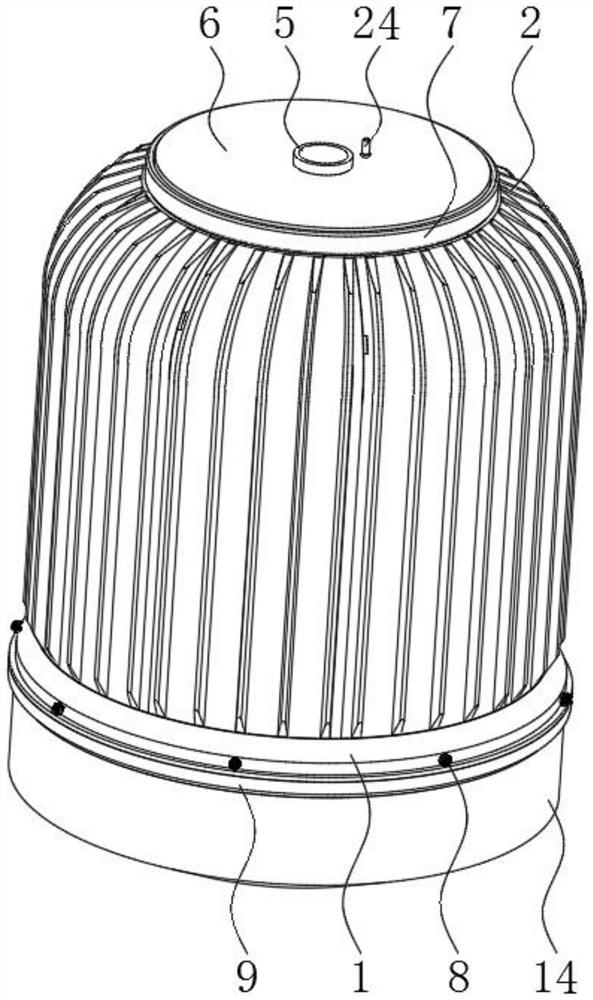

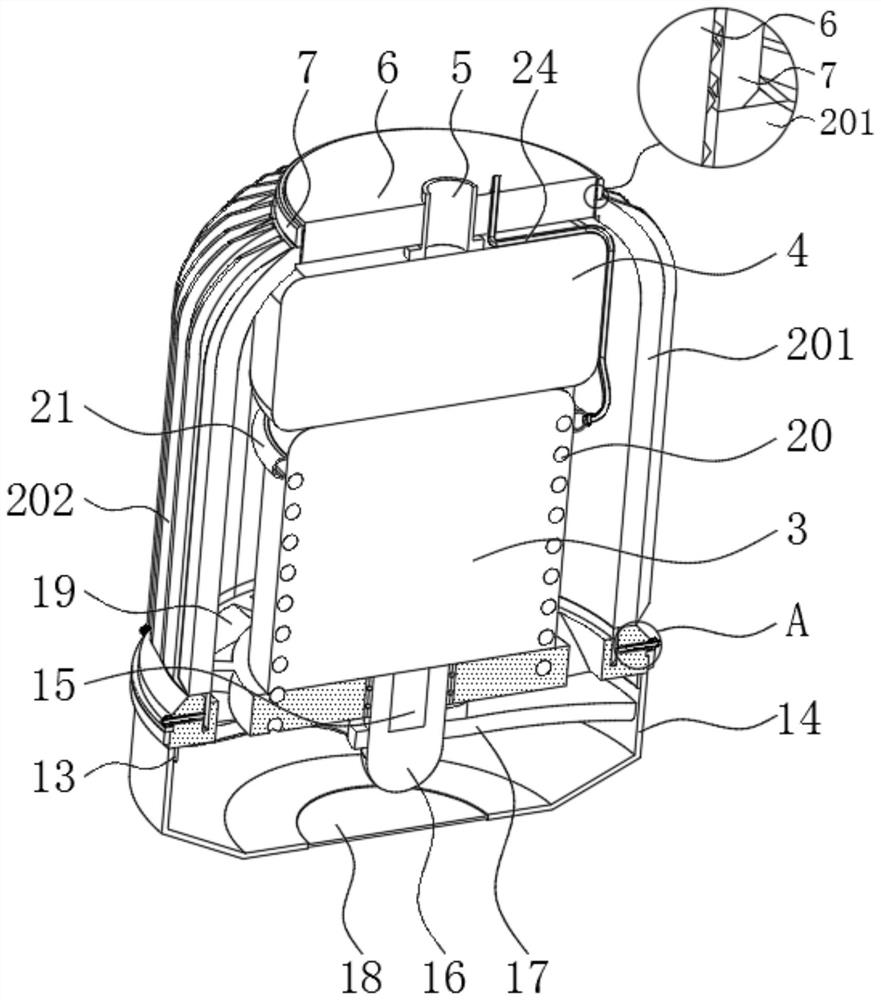

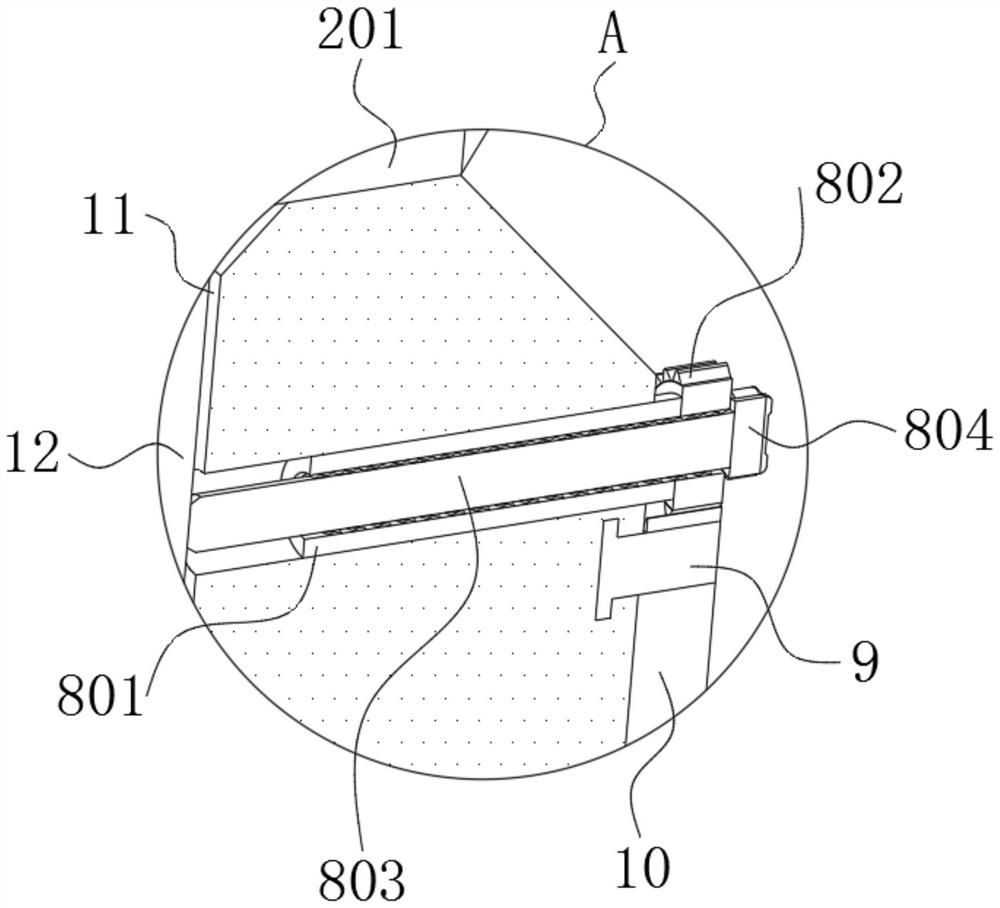

[0033] like Figure 1 to Figure 7 As shown, the vacuum cleaner motor in the embodiment of the present invention includes a base 1, the top of the base 1 is fixedly mounted with a motor shaft 3, and the top of the base 1 is movably connected with a number of housing components 2 located outside the motor shaft 3. A recovery box 4 is fixedly installed on the top, a sewage pipe 5 is fixedly connected to the top of the recovery box 4, a positioning plate 6 is fixedly sleeved on the outer surface of the sewage pipe 5, and a positioning sleeve 7 is threadedly sleeved on the outer surface of the positioning plate 6. The positioning sleeve The bottom of 7 is movably connected with the top of the housing assembly 2. The top of the base 1 is provided with a snap slot 11 at the bottom of the shell A number of locking mechanisms 8 are arranged on the sides. Due to the arrangement of the housing assembly 2 , it is convenient for the operator to disassemble the part, thereby facilitating th...

Embodiment 2

[0042] Compared with Embodiment 1, in this embodiment, the inside of the base 1 and the motor shaft 3 are screwed with a drain hole 20 , the bottom of the drain hole 20 penetrates through the base 1 and communicates with the interior of the protective cover 14 , and the sewage inlet groove 19 The top of the motor shaft 3 penetrates through the motor shaft 3 and is fixedly connected with a water conduit 21. The water conduit 21 is fixedly connected to the outer surface of the motor shaft 3. The provided water conduit 21 can facilitate the solenoid valve 22 and the connecting pipe 23 to perform simultaneous drainage of the plurality of drainage holes 20. Water is injected to make the distribution of water flow more uniform, and at the same time to ensure that the water flow quickly takes away more heat from the surface of the motor shaft 3; a solenoid valve 22 is fixedly connected to the right side of the water conduit 21, and a connecting pipe is fixedly connected to the right si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com