Auxiliary sprayer for external air cooling of direct current converter station

A DC converter station and sprinkler technology, which is applied in the direction of cooling/ventilation/heating transformation, can solve the problems of cooling water waste, accelerated aging of internal components, and affecting the service life of converter valves, etc., to achieve good cooling and good suction The effect of thermal effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

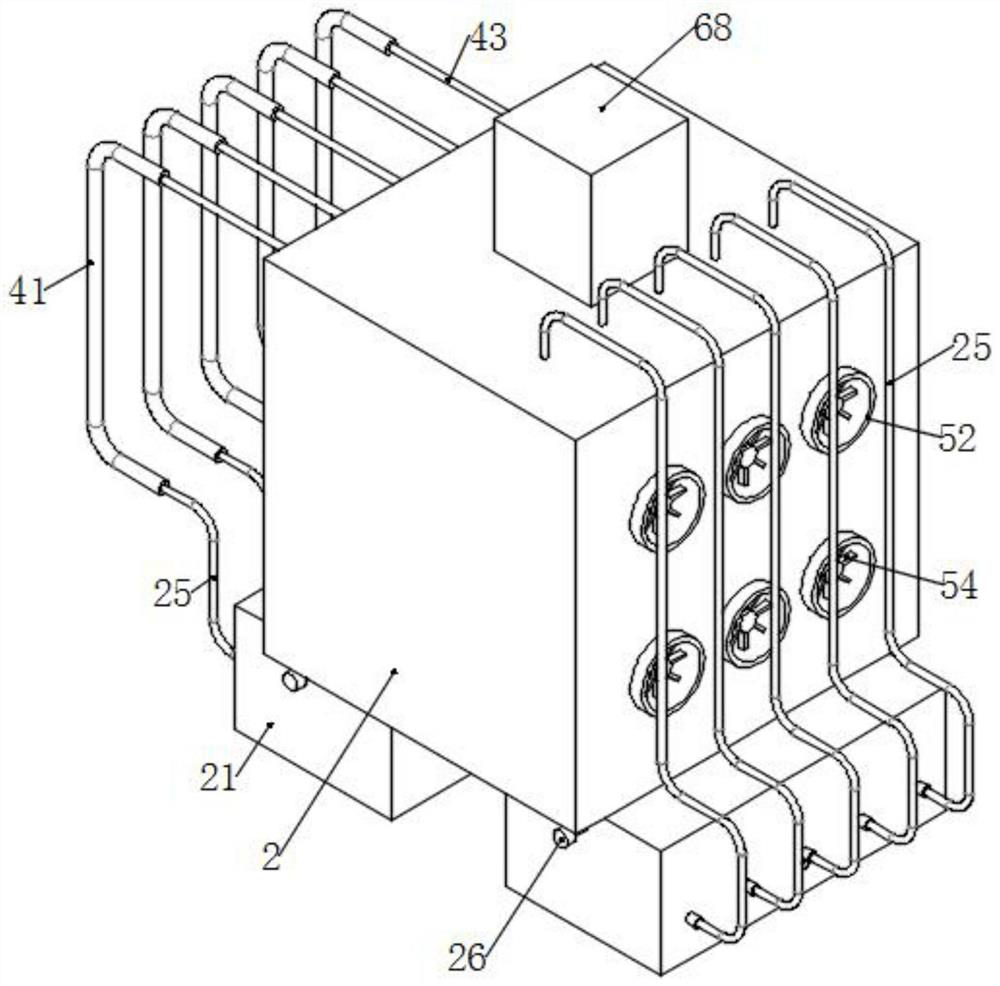

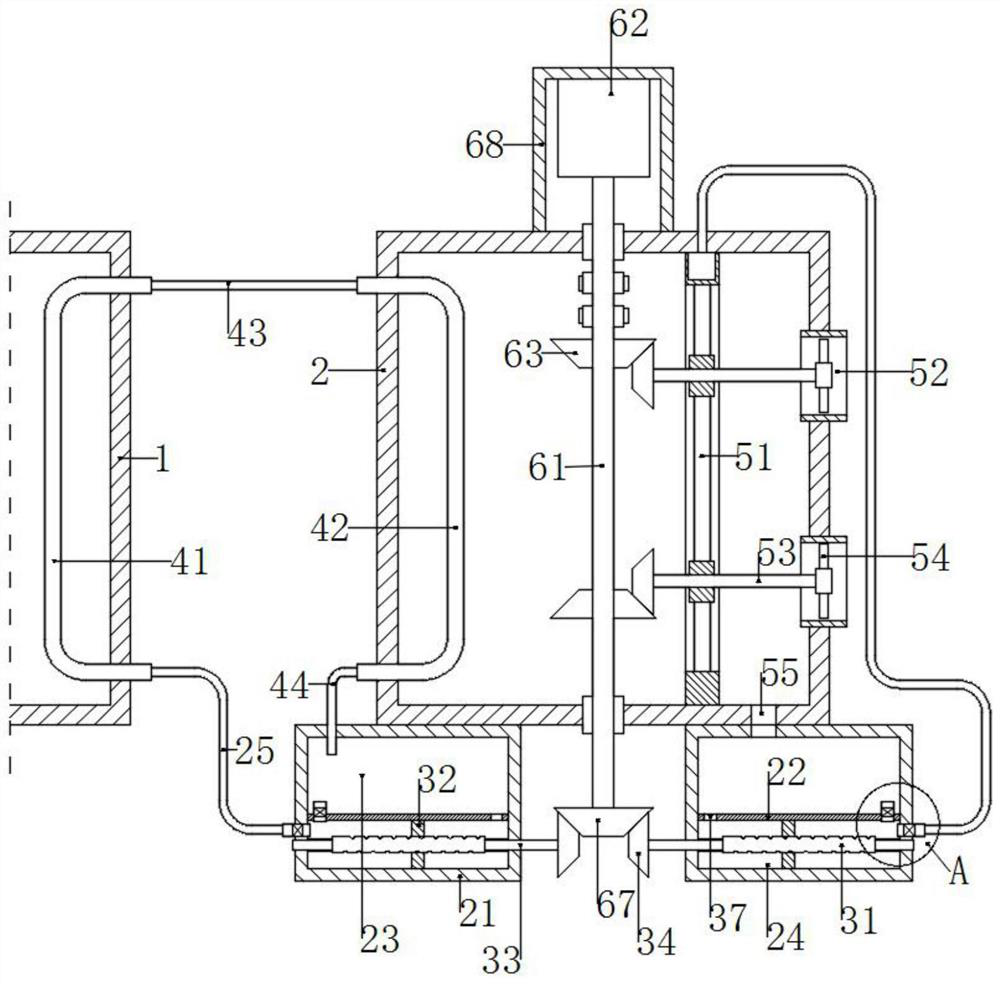

[0034] An auxiliary sprinkler for air cooling outside a DC converter station, comprising a converter valve housing 1, the converter valve housing 1 is used to install the converter valve, and also includes an air cooling cabinet 2, a pumping device, a water cooling device, air-cooled device and drive device;

[0035] The air-cooled cabinet 2 is located on the right side of the converter valve housing 1, and the bottom of the air-cooled cabinet 2 is fixedly fixed with a liquid storage tank 21 symmetrically. A partition 22 is fixed in the tank 21. The partition 22 divides the liquid storage tank 21 into an upper liquid storage cavity 23 and a lower pumping cavity 24. The side plates of the liquid storage tank 21 away from each other correspond to the pumping cavity 24. The pumping pipe 25 is evenly fixed in the longitudinal direction;

[0036] The pumping device is arranged in the pumping cavity 24, and the pumping devices on the left and right sides respectively transport the ...

Embodiment 2

[0049] On the basis of Embodiment 1, this embodiment discloses the specific technical features of the pumping device.

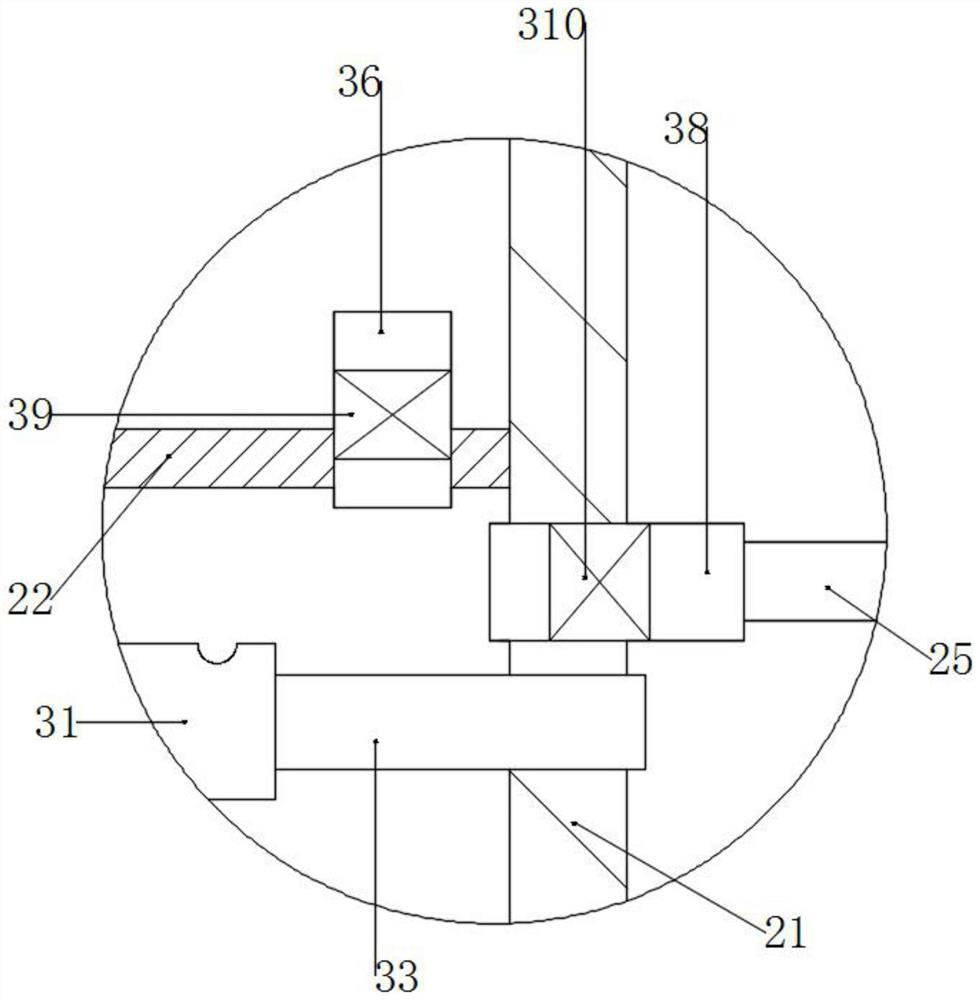

[0050] The pumping device includes a reciprocating screw 31 and a piston 32; the reciprocating screw 31 is connected to the pumping cavity 24 through a left-right symmetrical connecting shaft 33, and the head of the connecting shaft 33 near the center of the air-cooled cabinet 2 is fixed with a first driven The bevel gear 34, the driving device is used to drive the first driven bevel gear 34 to rotate, a guide rod 35 is also fixed in the pumping cavity 24, the piston 32 is sealed and slidably connected in the pumping cavity 24, and the piston 32 and the reciprocating screw rod 31 Meshing and sliding connection with the guide rod 35, the position close to the pumping pipe 25 on the partition plate 22 is evenly fixed with a liquid suction pipe 36 longitudinally, and the position away from the pumping pipe 25 on the partition plate 22 is longitudinally uniformly ...

Embodiment 3

[0054] On the basis of Embodiment 2, this embodiment discloses the specific technical features of the water distribution frame 51,

[0055] The interior of the water distribution frame 51 is fixedly connected with connecting rods 511 in a crisscross pattern. The connecting rods 511 divide the interior of the water distribution frame 51 into several spray spaces, and each spray space is fixed with a grille mesh 512. The connecting rods The intersection position of 511 is fixed with a swivel base 513, the rotating shaft 53 is rotatably connected in the swivel base 513, and the end of the rotating shaft 53 away from the fan blade group 54 is fixed with a second driven bevel gear 514, the driving device is used to drive the second driven The bevel gear 514 rotates, the top plate of the water distribution frame 51 is provided with a transfer cavity 515 , the bottom of the transfer cavity 515 is provided with a water drop hole 516 , and the heads of the pumping pipes 25 on the right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com