Casting device and casting method for centrifugal casting detection of boiler for casting

A centrifugal casting and boiler technology, applied in the direction of measuring devices, casting molding equipment, casting molds, etc., can solve problems such as segmentation, inability to flow, affect casting quality, etc., achieve uniform spraying, reduce resistance, and save spraying time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

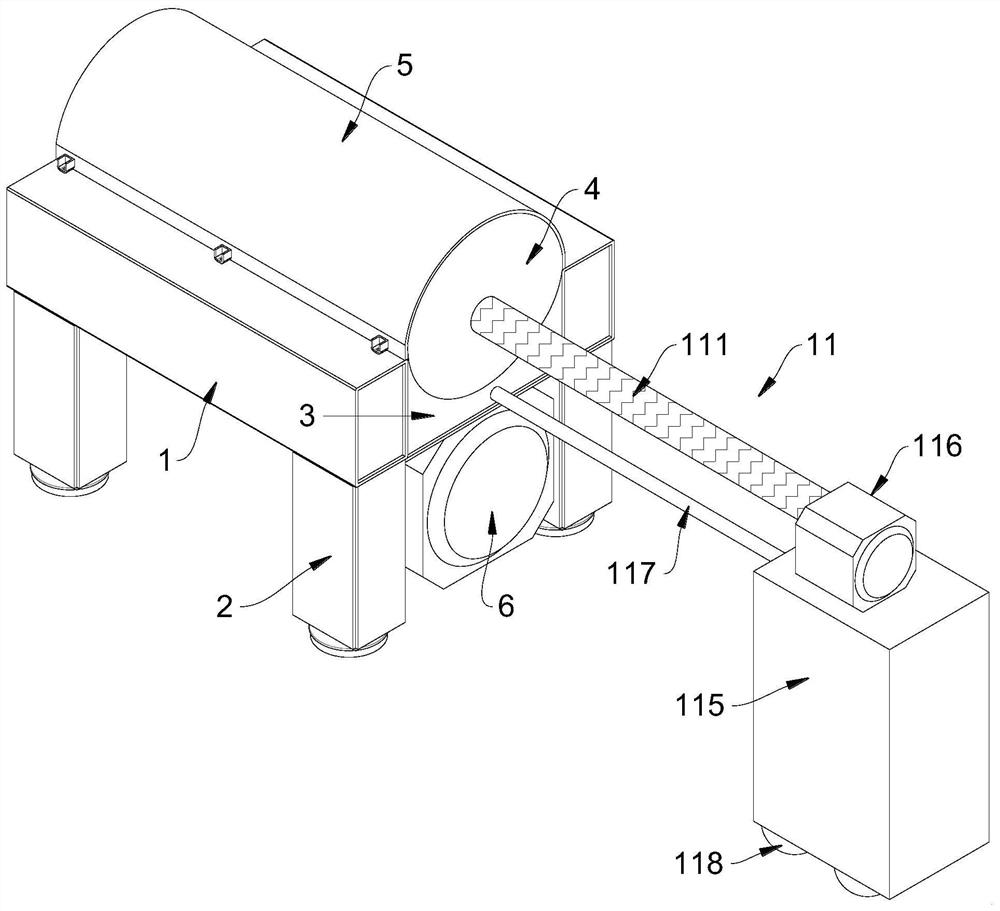

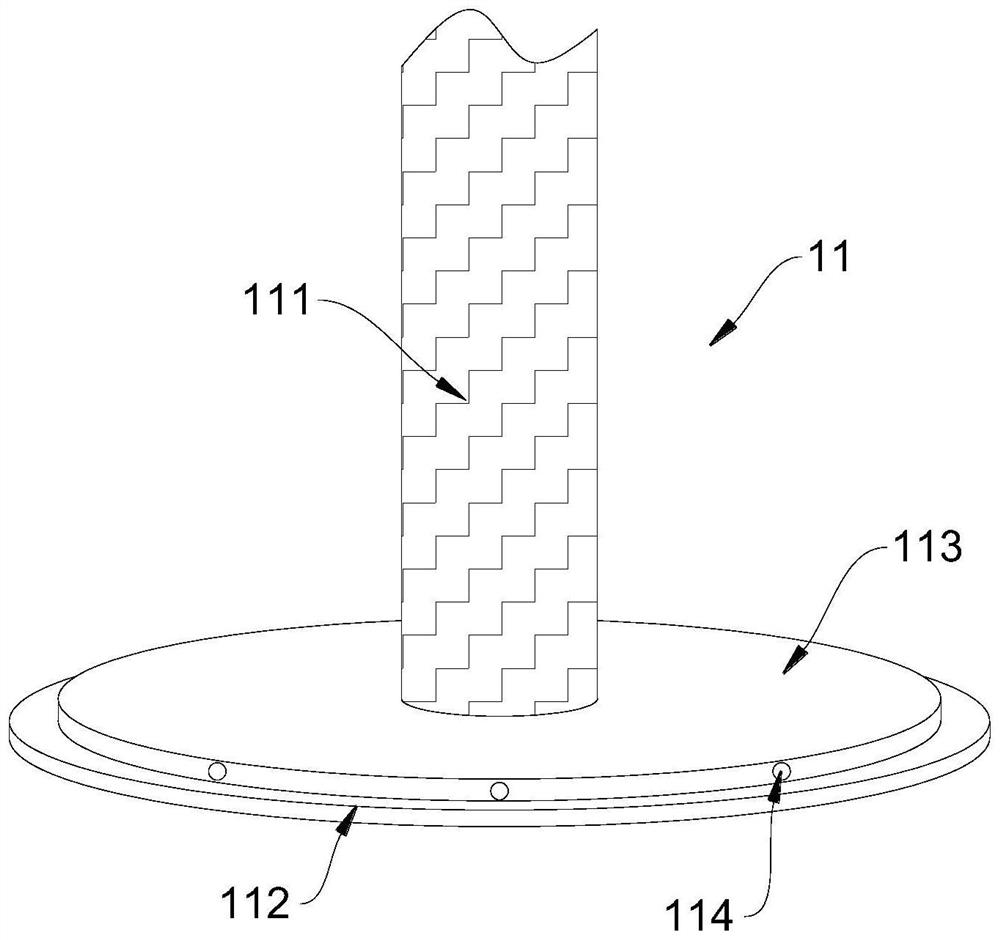

[0041] like Figure 1 to Figure 3 Shown: the trigger mechanism 11 includes a first screw rod 111 screwed through the right side of the mold 4 , the left side of the first screw rod 111 is rotatably connected with a rear baffle 112 , and the right side of the first screw rod 111 A second motor 116 is rotatably connected, and the lower end of the second motor 116 is fixedly connected with a base 115, the lower end of the base 115 is provided with a pulley 118, and the upper left side of the base 115 is provided with a switch for controlling the water cooling mechanism, and the switch A triggering rope 117 is fixedly connected with the bracket 3 .

[0042] When working, during the casting process, with the rotation of the mold 4, since the mold 4 and the first screw rod 111 are connected by a screw drive, and the first screw rod 111 is restricted by the second motor 116 and cannot rotate, when the mold 4 During rotation, the first screw rod 111 is driven to move from the left side...

Embodiment 2

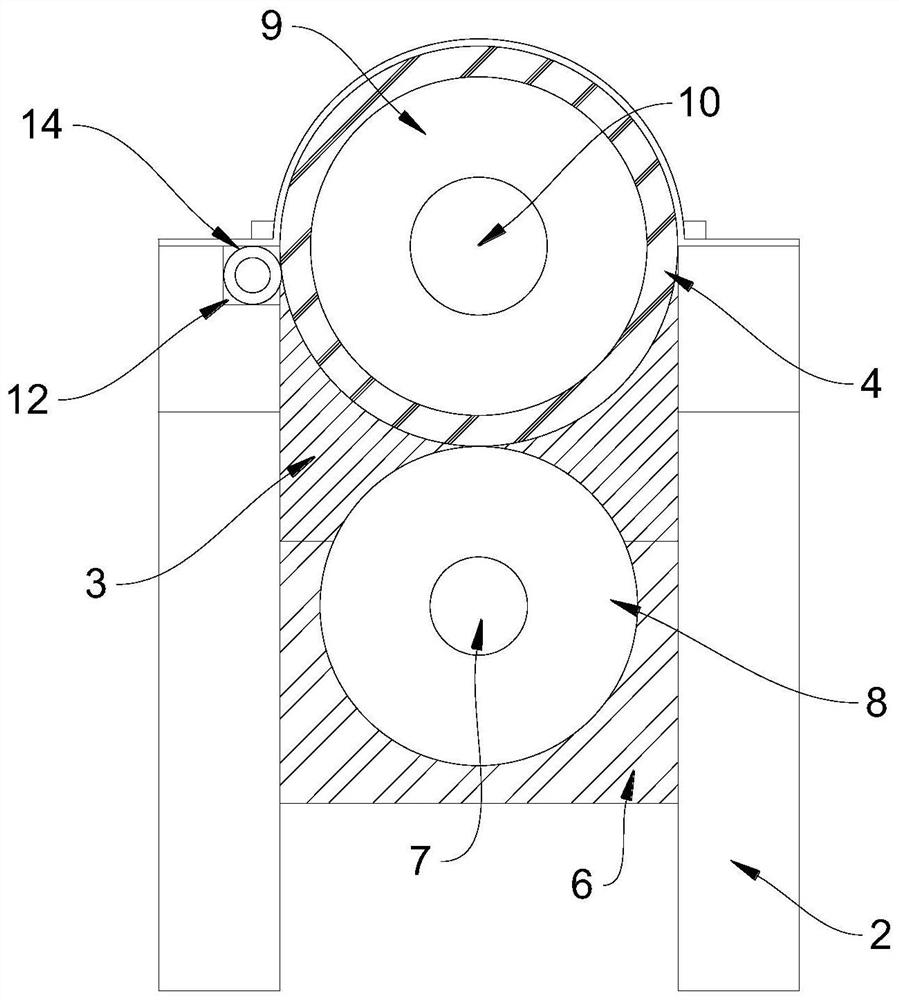

[0047] like figure 2 and Figure 5 Shown: the trigger mechanism 11 further includes a cavity 12 opened at the front of the workbench 1, and the interior of the cavity 12 is fixedly connected with a second screw rod 13, and the outer screw sleeve of the second screw rod 13 is screwed with The spiral sleeve 14 is in close contact with the surface of the mold 4, and the inner wall of the right side of the cavity 12 is provided with a switch for controlling the water cooling mechanism.

[0048] During operation, when the mold 4 rotates, it contacts with the screw sleeve 14 to drive the screw sleeve 14 to rotate. Since the screw sleeve 14 is connected with the second screw rod 13 in a screw drive, when the screw sleeve 14 rotates, it rotates along the second screw. The rod 13 is displaced to the right until the screw sleeve 14 moves to the far right of the second screw rod 13, indicating that the melt has filled the inner wall of the mold 4. At this time, the screw sleeve 14 sque...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com