Food safety accident multi-factor risk grade evaluation equipment and evaluation method thereof

A risk level, food safety technology, applied in chemical instruments and methods, data processing applications, packaging, etc., can solve the problems of automatic rotation, long time, inconvenient identification and search of test tubes, etc., to achieve easy search and place, and reduce selection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] A multi-factor risk level assessment method for food safety accidents, the level assessment method is as follows:

[0046] Step 1: Obtain sample food sampling data;

[0047] Step 2, constructing a food sampling knowledge map according to the sample food sampling data;

[0048] Step 3, training a deep learning network GCN model based on the food sampling inspection knowledge map and the sample food sampling inspection data to obtain a food risk prediction model;

[0049] Step 4: Receive the category information of the food to be tested and the information of the items to be sampled;

[0050] Step 5, based on the category information and the information of the items to be sampled, perform map extraction in the food sampling knowledge map to obtain map data to be detected;

[0051] Step 6: Inputting the to-be-detected atlas data into the food risk prediction model for calculation to obtain the target risk level corresponding to the to-be-detected food.

[0052] As a pre...

Embodiment 2

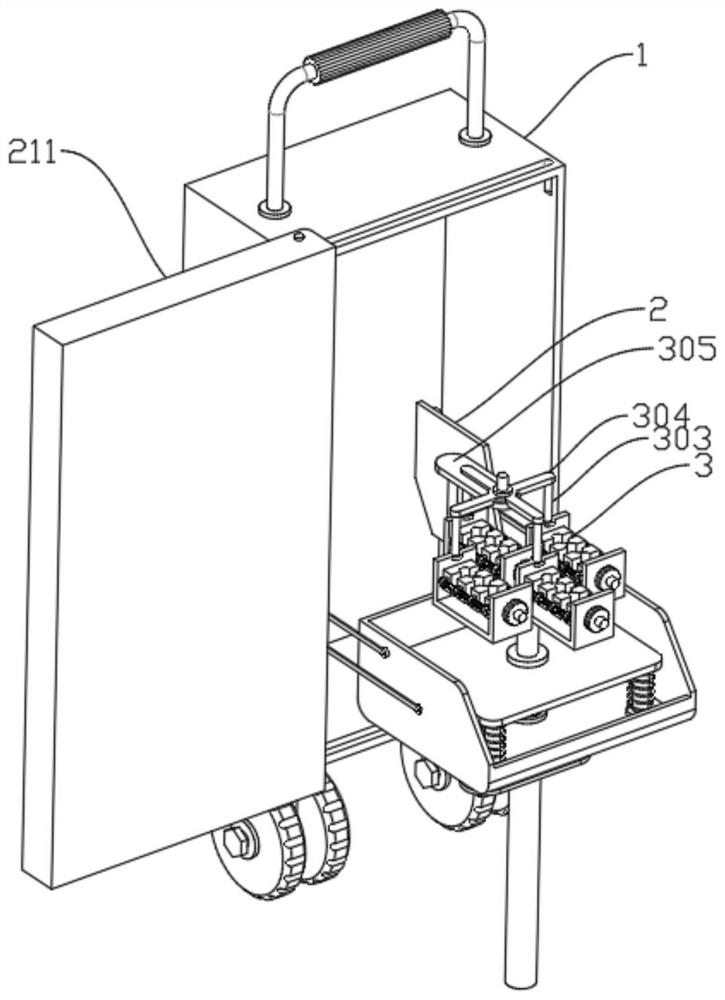

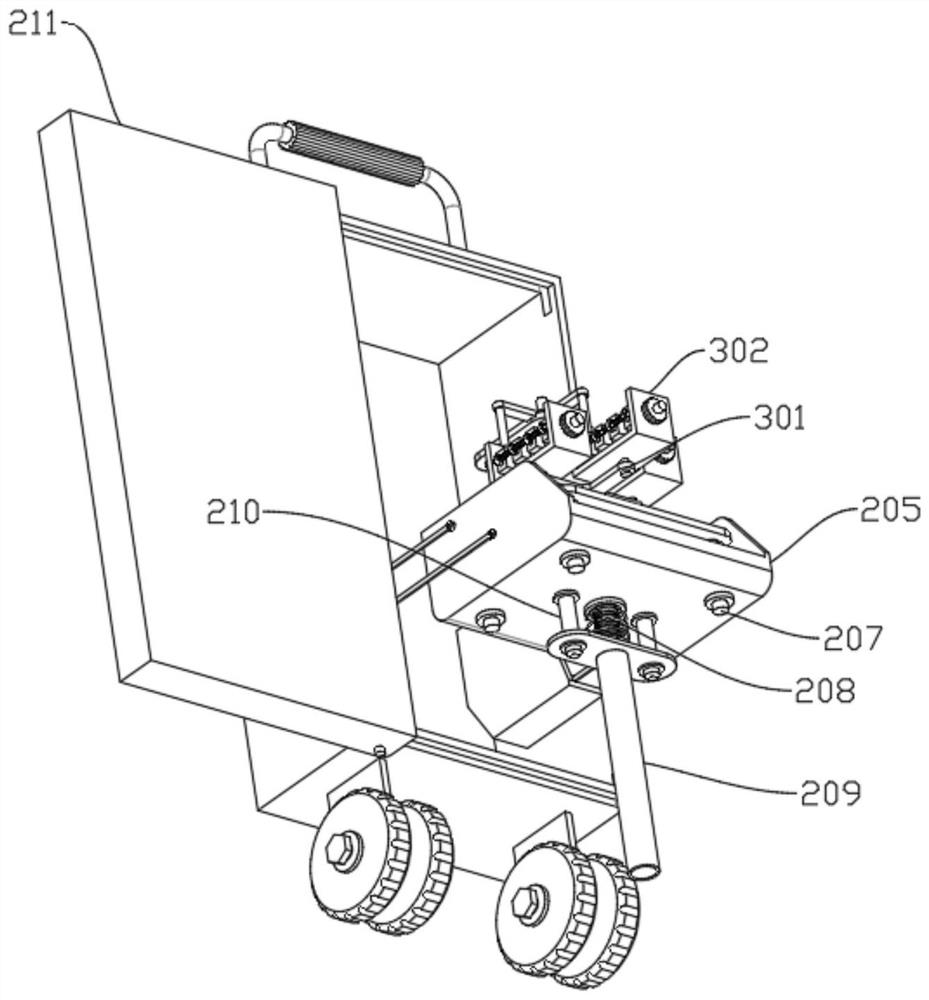

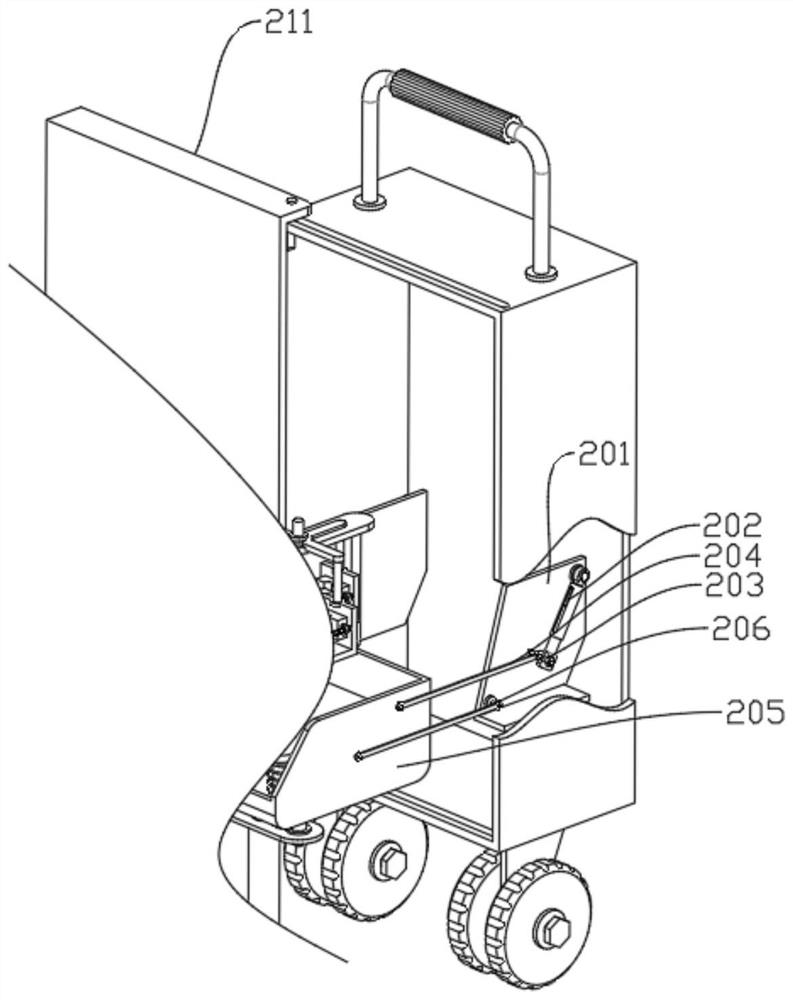

[0057] Please refer to the drawings to the drawings, according to a multi-factor risk level assessment method for food safety accidents provided in the first embodiment, a multi-factor risk level assessment device for food safety accidents is now proposed, including a box body 1, the inner lower end of the box body 1 A removal mechanism 2 is provided. The upper end of the removal mechanism 2 is provided with a partition mechanism 3. The removal mechanism 2 includes a mounting plate 201, a spring telescopic cylinder 202, a power rod 203, a main rod 204, a groove tray 205, and a support rod 206. Inside the box 1 Both the left and right ends are fixedly connected with a mounting plate 201, the upper end of the mounting plate 201 is rotatably connected with a spring telescopic cylinder 202, the lower end of the spring telescopic cylinder 202 is rotatably connected with a power rod 203, and the left end of the power rod 203 is fixedly connected with a main force rod 204, the main for...

Embodiment 3

[0060] Referring to the drawings, the partition mechanism 3 includes a power swash plate 301, a placement plate 302, a docking rod 303, an auxiliary swash plate 304, and a bending rod 305. The upper end of the power spring threaded rod 208 is fixedly connected with the power swash plate 301, the power cross plate A placing plate 302 is evenly connected in the diameter of the plate 301, the upper end of the placing plate 302 is fixedly connected with a docking rod 303, the upper end of the docking rod 303 is rotatably connected with an auxiliary swash plate 304, and the upper end of the auxiliary swash plate 304 is rotatably connected with a bending rod 305. The lower end of the rod 305 is fixedly connected to one end of the Aocha tray 205, and the left end of the placing plate 302 is fixedly connected with a driving circular groove rubber plate 306. The right end of the driving circular groove rubber plate 306 is provided with a plurality of power rubber plates 307 at equal dist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com