Rotational molding polyethylene material with spraying-free metal effect as well as preparation method and application of rotational molding polyethylene material

A metal effect, polyethylene technology, applied in the field of engineering plastics, can solve the problems of easy formation of pores, poor surface appearance, phase separation, etc., and achieve the effect of high metal gloss and reducing flow lines and weld lines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~18

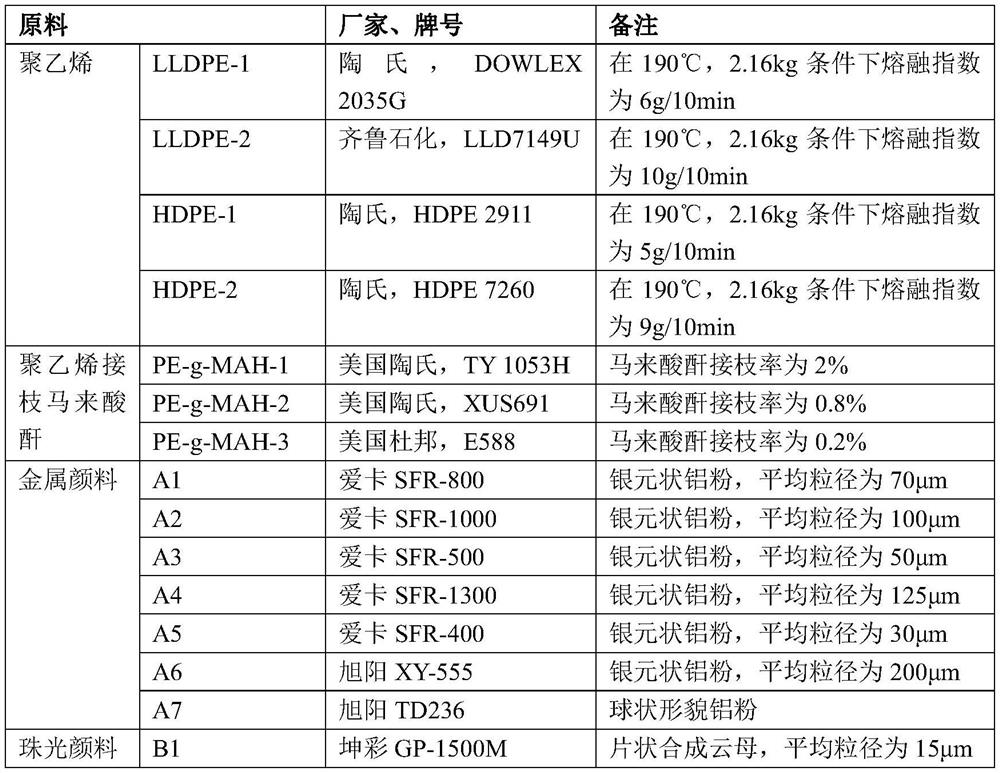

[0065] Embodiments 1 to 18 respectively provide a rotomolded polyethylene material, the component contents are shown in Table 1, and the preparation method is as follows:

[0066] According to Table 1, each component is mixed and added to a twin-screw extruder, melt-mixed, extruded and pelletized to obtain rotomolded polyethylene pellets;

[0067] Adding the rotomolded polyethylene pellets to a pulverizer, and pulverizing to obtain a powdered rotomolded polyethylene material;

[0068] The length-diameter ratio of the twin-screw is 46:1, the extrusion temperature is 190-230°C, and the rotational speed is 400 rpm; the rotational speed of the pulverizer is 3000HZ, and the milling current is 75A.

[0069] Table 1 Component content (parts by weight) of the rotationally molded polyethylene materials of Examples 1 to 18

[0070]

[0071]

Embodiment 3

[0100] In Example 3 and Examples 13-18, when the average particle size of the metallic pigment is preferably 70-100 μm, and the average particle size of the pearlescent pigment is preferably 15-20 μm (Examples 3, 13, 16), rotomolding polyethylene materials higher gloss, less flow lines and weld lines

[0101] According to the test results in Table 4, in Comparative Examples 1 and 2, the average particle size of the metallic pigments was too small or too large, and in Comparative Examples 4 and 5, the average particle size of the pearlescent pigments was too small or too large. Can not play an effective synergistic effect, the obtained rotomolded polyethylene material has poor gloss, all less than 70, and the surface of the rotomolded polyethylene product has certain flow lines and weld lines.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com