Method for manufacturing metal-like packing paper

A metal texture and production method technology, applied in the production field of metal texture packaging paper, can solve the problems of high production process requirements, great difficulty, poor product surface flatness, etc., achieve high specular reflection effect, reduce the degree of diffusion, improve The effect of packaging grade

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

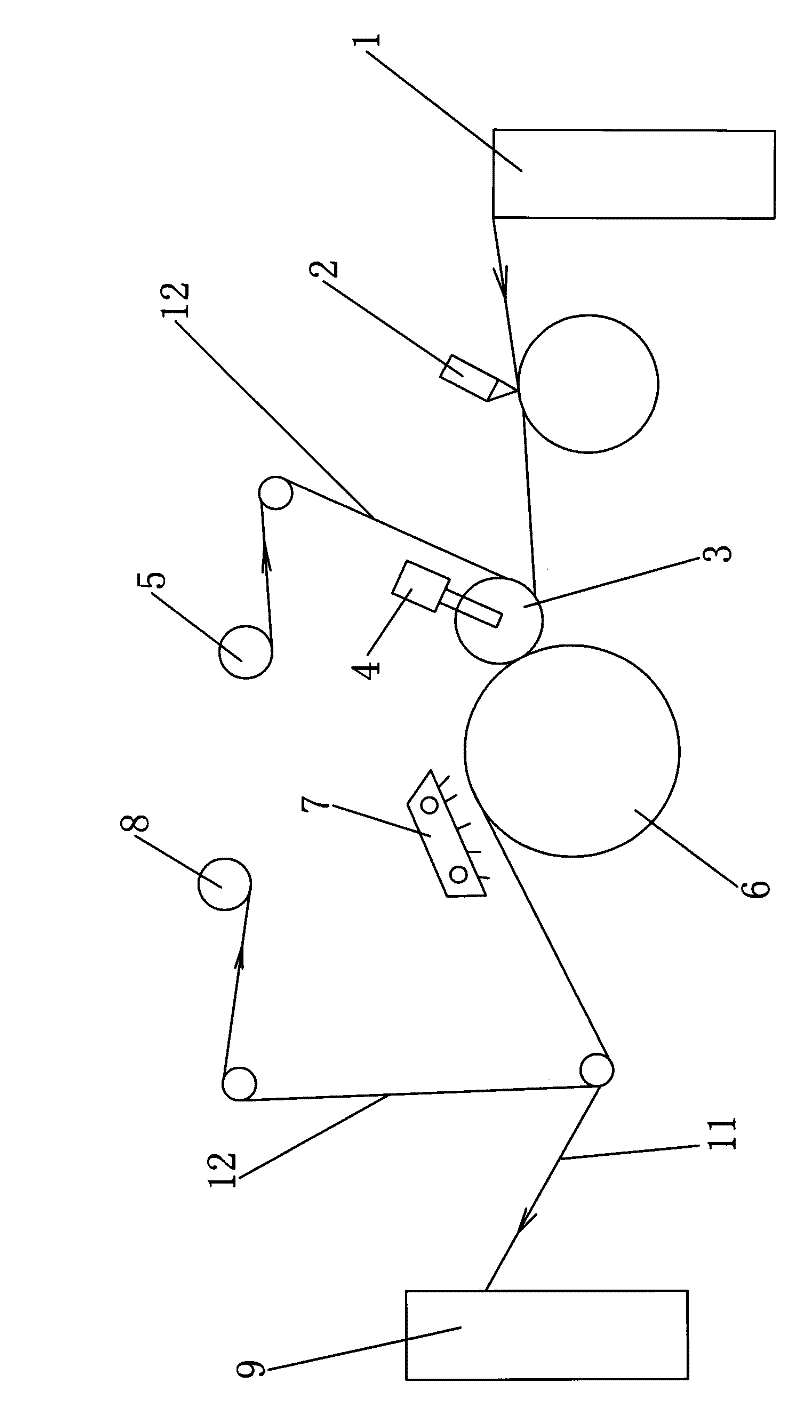

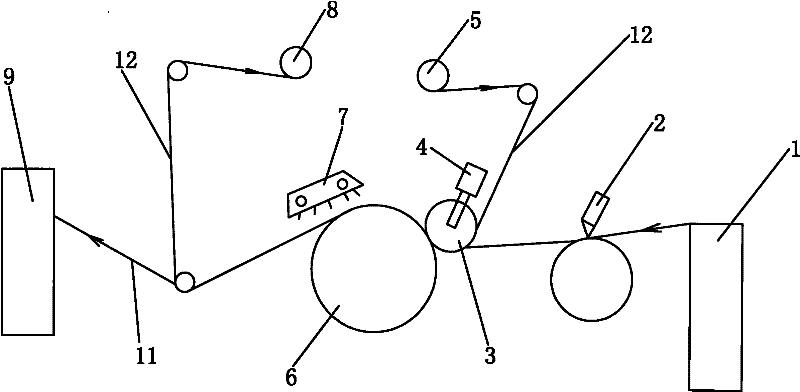

[0023] figure 1 As shown, the production method of the metal texture wrapping paper comprises the following steps in sequence: (1), the wrapping paper unwinding mechanism 1 unwinds the wrapping paper base 11, and coats the surface of the wrapping paper base with UV silver by the coating mechanism 2. Ink (so-called UV silver ink, is exactly the silver ink that solvent is UV oil); Laser film unwinding mechanism 5 will be printed with the laser film 12 of holographic concave-convex pattern unwinding; (2), wrapping paper base 11 is coated with UV The surface of the silver ink is pressed with the laser film 12 printed with holographic concave-convex patterns, so that the surface of the UV silver ink produces holographic concave-convex patterns; 6 apply pressure; (3), after pressing, utilize ultraviolet lamp 7 to irradiate, make the UV oil solvent in the UV silver ink dry (cure) immediately after irradiating, then wrapping paper 11 paper bases and laser film 12 are peeled off, obtai...

Embodiment 2

[0026] The production method of the metal texture wrapping paper comprises the following steps in sequence: (1), coating the silver ink containing aqueous solvent on the surface of the wrapping paper base; (2), smoothing the surface and the surface of the wrapping paper base coated with the silver ink Film pressing, after pressing, the composite material of wrapping paper base and film is sent to an oven for drying; (3), the film and wrapping paper base are peeled off to obtain a mirror-like smooth surface with bright silver luster Wrapping paper, finally rewinding the wrapping paper.

[0027] In the step (2) in the above-mentioned embodiment 2, an oven may not be used, and after the composite material of the wrapping paper base and the film is naturally dried, step (3) is performed to peel off the film and the wrapping paper base.

[0028] In the above examples, the silver ink containing the aqueous solvent can also be changed to the gold ink containing the aqueous solvent, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com