Metal-luster paint-spraying -free material and preparation method thereof as well as paint-spraying -free wire

A technology of metallic luster and metal powder, applied in the field of paint-free materials and their preparation, and paint-free wires, can solve the problems of reduced material processing performance, low material melt fluidity, poor compatibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

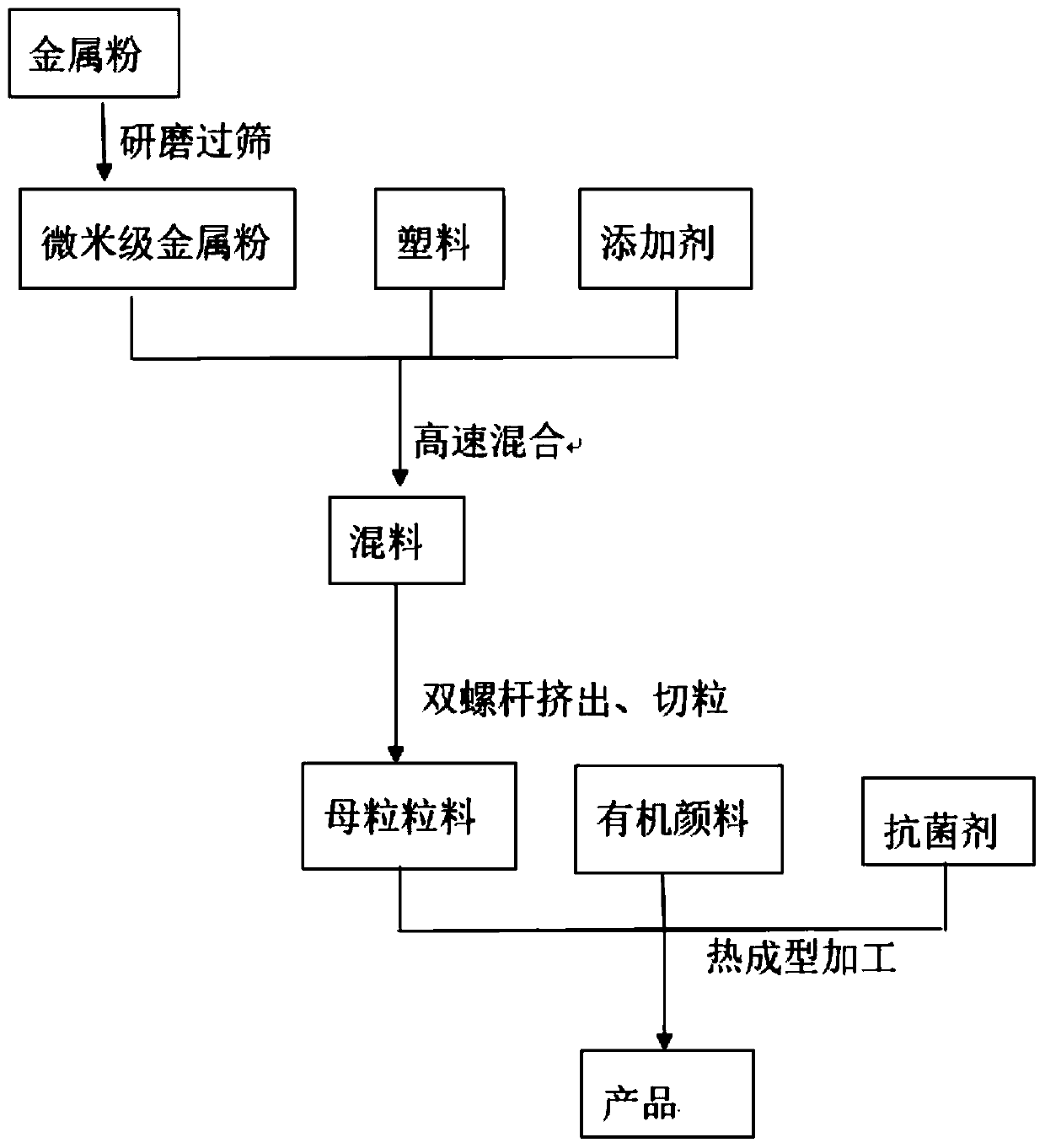

[0036] The present invention provides a method for preparing a paint-free material with metallic luster described in the above technical solution, comprising the following steps:

[0037] Mix micron-sized metal powder, plasticizer, toughener, lubricant and plastic in a high-speed mixer to obtain a mixture, granulate, and dry to obtain blended masterbatch pellets;

[0038] The blended masterbatch pellets are mixed with an antibacterial agent and an organic pigment to obtain a paint-free material with metallic luster.

[0039] see figure 1 , figure 1 The specific process flow chart that has metallic luster free paint-free material that the present invention provides, by figure 1 It can be seen that:

[0040]The metal is crushed and sieved to obtain micron-sized metal powder; the micron-sized metal powder, plastic, and additives are mixed at high speed to obtain a compound; the compound is twin-screw extruded and pelletized to obtain a masterbatch; the masterbatch, colorant an...

Embodiment 1

[0051] (1) Micron-sized metal powder (being copper-zinc alloy powder, wherein copper accounts for 97%, zinc accounts for 3%), plasticizer (polyethylene glycol), lubricant (zinc stearate), toughening agent ( Nano-silica) and ABS are taken out after mixing 5min in a high-speed mixer in proportion to obtain a mixture; wherein, copper-zinc alloy powder 5%, polyethylene glycol 2%, zinc stearate 1%, nanometer dioxide Silicon 2%, ABS 90%.

[0052] (2) Melt-extrude the obtained blend through a twin-screw extruder and pelletize it. The temperatures of the 1-6 sections of the extruder are respectively 175°C, 175°C, 180°C, 185°C, 190°C and 190°C to obtain Masterbatch pellets are fully dried at 80°C for 24 hours.

[0053] (3) Mix the obtained masterbatch with organic pigment and antibacterial agent (enrofloxacin hydrochloride) in a high-speed mixer in a certain proportion for 5 minutes and then take it out. The ratio is: 98.5% of masterbatch, 0.5% of organic pigment, enrofloxacin hydroch...

Embodiment 2

[0057] Micron-sized metal powder (copper-zinc alloy powder, in which copper accounts for 95% and zinc accounts for 5%), plasticizer (palm oil), lubricant (polyethylene wax), toughening agent (nanocellulose) and PP Take it out after mixing in a high-speed mixer for 5 minutes to obtain a mixture; wherein, 5.5% of copper-zinc alloy powder, 2.5% of palm oil, 2% of polyethylene wax, 1% of nanocellulose, and 89% of PP.

[0058] (2) Melt-extrude the obtained blend through a twin-screw extruder and pelletize it. The temperatures of the 1-6 sections of the extruder are respectively 170°C, 170°C, 175°C, 180°C, 180°C and 180°C to obtain Masterbatch pellets should be fully dried at 80°C for 12-24 hours.

[0059] (3) The obtained masterbatch pellets are mixed with organic pigments and antibacterial agents (nano-titanium dioxide and nano-silver are blended at a mass ratio of 1:1) in a high-speed mixer in proportion to take out after mixing for 5 minutes, wherein the masterbatch accounts for...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Flexural modulus | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com