Special master batch for hot press molding transparent polypropylene as well as preparation method and application of master batch

A technology of transparent polypropylene and hot-pressing molding, applied in the field of special polypropylene masterbatch, can solve the problems of large fluctuation in transparency of disposable water cups, difficult dispersion of transparent nucleating agents, rising production costs, etc., and achieve uniform product quality. Stable, improved interface effect, low production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-89

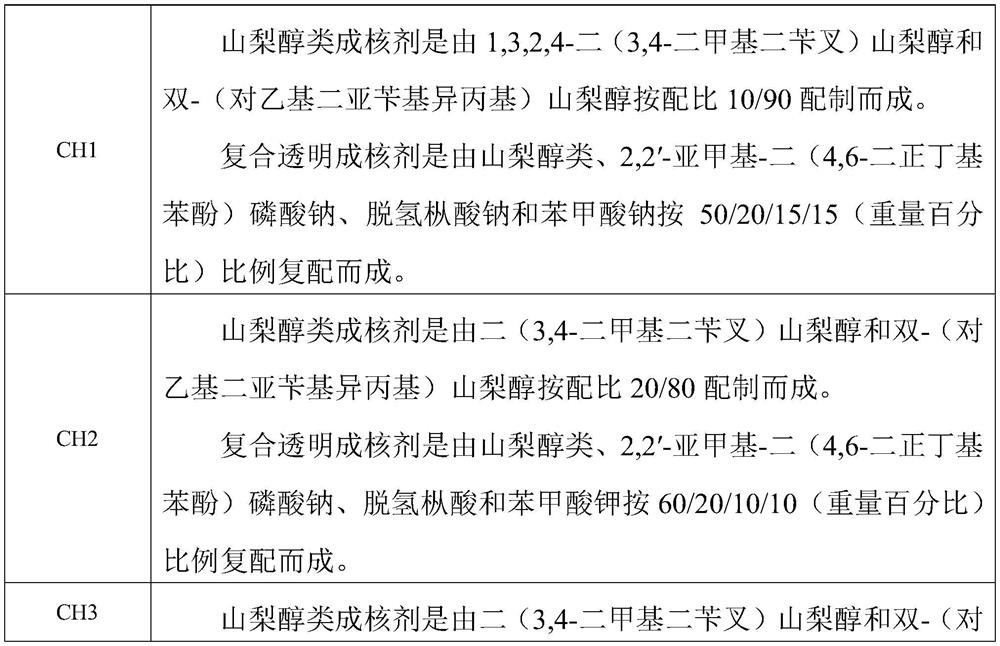

[0075] The following table 2 is the masterbatch composition table (unit: weight percent) of the hot-pressed transparent polypropylene special-purpose masterbatches of Examples 1 to 89 of the present invention:

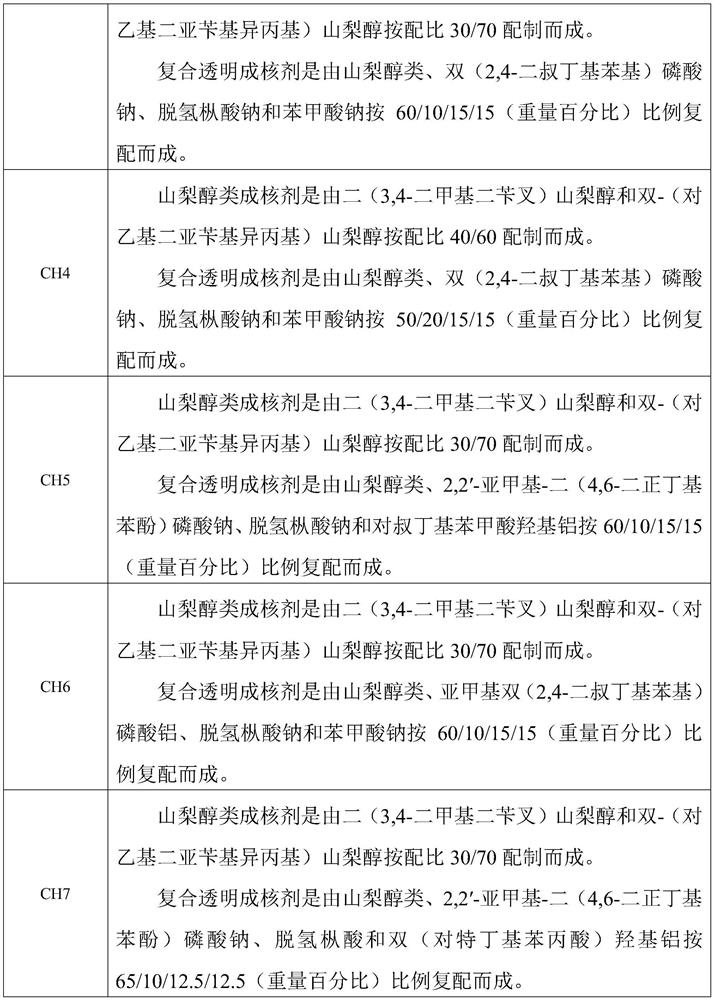

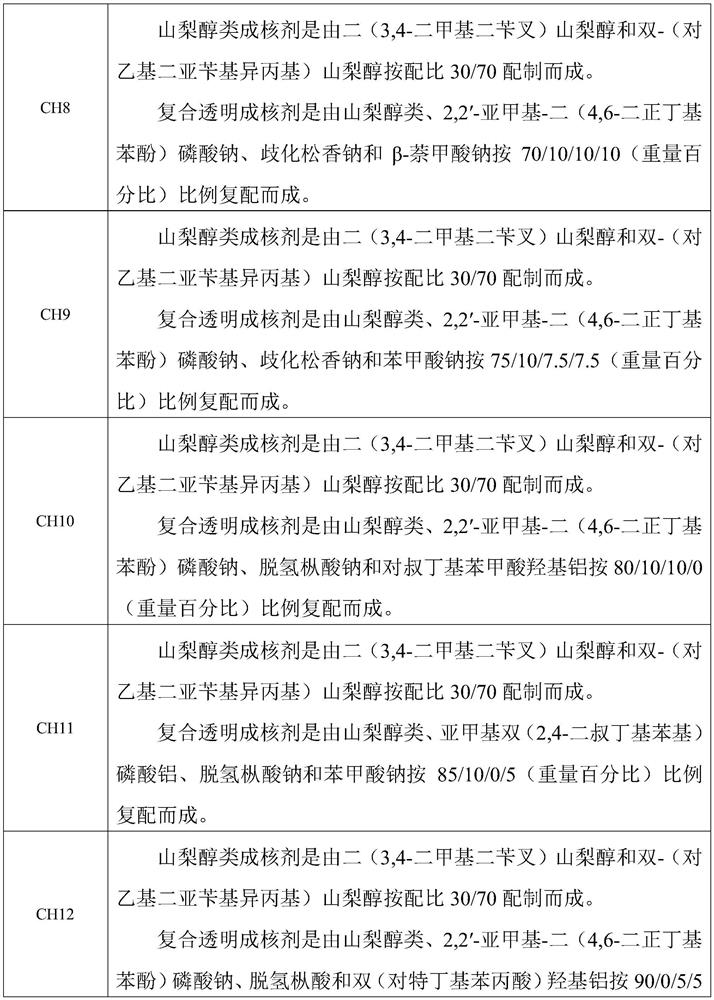

[0076] The specific embodiment of the special master batch of table 2 thermoforming transparent polypropylene

[0077]

[0078]

[0079]

[0080]

[0081]

[0082]

[0083]

[0084]

[0085]

[0086]

[0087]

[0088]

[0089]

[0090]

Embodiment 90

[0092] The preparation method of the special masterbatch for thermoforming transparent polypropylene of the present embodiment comprises the following steps:

[0093] Step (1) Blending polypropylene and auxiliary agents: According to the special masterbatch formula for hot-pressing transparent polypropylene in Examples 1-89, polypropylene resin and composite transparent nucleating agent, compatibilizer, lubricant, antioxidant masterbatch are mixed together. The materials are mixed in a high-speed mixer;

[0094] Step (2) twin-screw extruder melt granulation: add the blended material into the extruder hopper, melt and extrude the strands through the twin-screw extruder, and then cool in a water tank and air-dry and cut into pellets. Special masterbatch.

[0095] Preferably, in the step (1), the polypropylene resin, the composite transparent nucleating agent, the compatibilizer, the lubricant, and the antioxidant masterbatch are mixed in a high-speed mixer for 10-20 minutes, an...

Embodiment 91

[0097]The special masterbatch products of hot-pressed transparent polypropylene of Example 1 to Example 89 are detected, and their technical indicators are respectively shown in Table 3:

[0098] The technical index of the special masterbatch for thermoforming transparent polypropylene of table 3 embodiment 1~89

[0099]

[0100]

[0101]

[0102]

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| oxidation induction time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com