Plum syrup essence and production process thereof

A plum soup essence and production process technology, applied in the directions of essential oils/spice, fat production, food science, etc., can solve the problems of loss of natural flavor, bad cooking taste, etc., and achieve the effect of improving aroma and taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

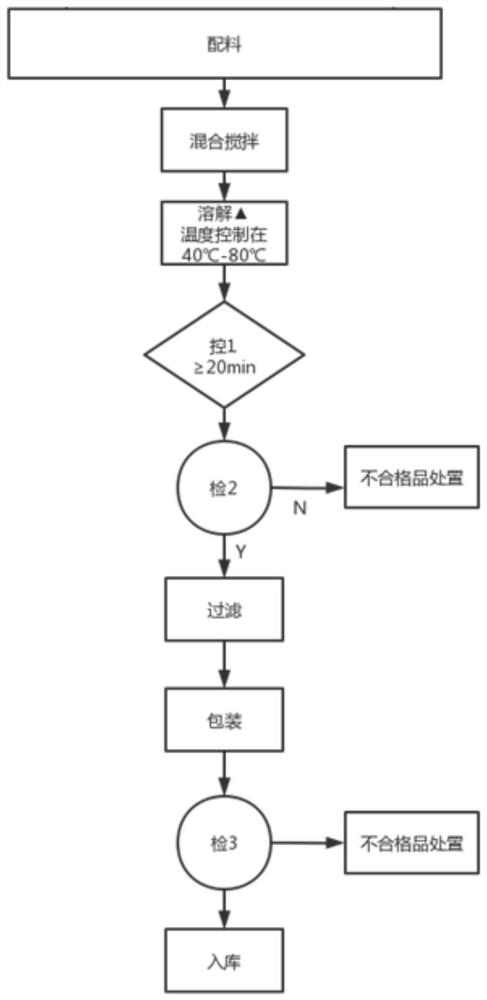

[0047] like figure 1 shown, figure 1 Shown is the production process flow chart of the essence in the present invention.

[0048] Specifically, a kind of production technology of sour plum soup essence, production technology comprises the following steps:

[0049] (1) Quality inspection of raw materials, according to the number of doses:

[0050] Benzyl acetate: 0.0039 parts, Geranyl acetate: 0.0007 parts, Dimethylbenzyl orthoester butyrate: 0.0092 parts, Ethyl 3-hydroxyhexanoate: 0.0070 parts, Peach aldehyde: 0.0007 parts, Benzaldehyde: 0.0779 parts , hexanal propylene glycol acetal: 0.0079 parts, benzyl alcohol: 0.0779 parts, leaf alcohol: 0.0076 parts, acetic acid: 0.9699 parts, propionic acid: 0.1279 parts, vanilla bean tincture: 1.5599 parts, benzyl acetate: 0.0099 parts, acetic acid Phenylethyl ester: 0.0032 part, methyl ionone: 0.0266 part, sweet-scented osmanthus extract: 0.1166 part, iris extract: 0.0332 part, jasmine absolute oil: 0.0107 part, ethionone: 0.0332 pa...

Embodiment 2

[0067] A production process of sour plum soup essence, the production process comprises the following steps:

[0068] (1) Quality inspection of raw materials, according to the number of doses:

[0069] Benzyl acetate: 0.0040 parts, Geranyl acetate: 0.0008 parts, Dimethylbenzyl orthoester butyrate: 0.0093 parts, Ethyl 3-hydroxyhexanoate: 0.0080 parts, Peach aldehyde: 0.0008 parts, Benzaldehyde: 0.0780 parts , hexanal propylene glycol acetal: 0.0080 parts, benzyl alcohol: 0.0780 parts, leaf alcohol: 0.0077 parts, acetic acid: 0.9700 parts, propionic acid: 0.1280 parts, vanilla bean tincture: 1.5600 parts, benzyl acetate: 0.0100 parts, acetic acid Phenylethyl ester: 0.0033 part, methyl ionone: 0.0267 part, sweet-scented osmanthus extract: 0.1167 part, iris extract: 0.0333 part, jasmine absolute oil: 0.0108 part, ethionone: 0.0333 part, propylene glycol: 97.9132 part,

[0070] The preparation of each raw material is completed.

[0071] (2) put the prepared raw materials into the...

Embodiment 3

[0079] A production process of sour plum soup essence, the production process comprises the following steps:

[0080] (1) Quality inspection of raw materials, according to the number of doses:

[0081] Benzyl acetate: 0.0041 parts, Geranyl acetate: 0.0009 parts, Dimethylbenzyl orthoester butyrate: 0.0094 parts, Ethyl 3-hydroxyhexanoate: 0.0081 parts, Peach aldehyde: 0.0009 parts, Benzaldehyde: 0.0781 parts , hexanal propylene glycol acetal: 0.0081 parts, benzyl alcohol: 0.0781 parts, leaf alcohol: 0.0078 parts, acetic acid: 0.9701 parts, propionic acid: 0.1281 parts, vanilla bean tincture: 1.5601 parts, benzyl acetate: 0.0101 parts, acetic acid Phenethyl ester: 0.0034 part, methyl ionone: 0.0268 part, osmanthus extract: 0.1168 part, iris extract: 0.0334 part, jasmine absolute oil: 0.0109 part, ethionone: 0.0334 part, propylene glycol: 97.9133 part,

[0082] The preparation of each raw material is completed.

[0083] (2) put the prepared raw materials into the mixing tank and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com