Toothpaste containing folium artemisiae argyi and rosemary leaf extracts and preparation method thereof

The technology of extracting rosemary leaves and argyi leaves is applied in the field of toothpaste containing argyi leaves and rosemary leaf extracts and its preparation field, which can solve the problems of influence of toothpaste stability, increase cost and the like, achieve slightly spicy taste and reduce wear rate. , Long-term stability and strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

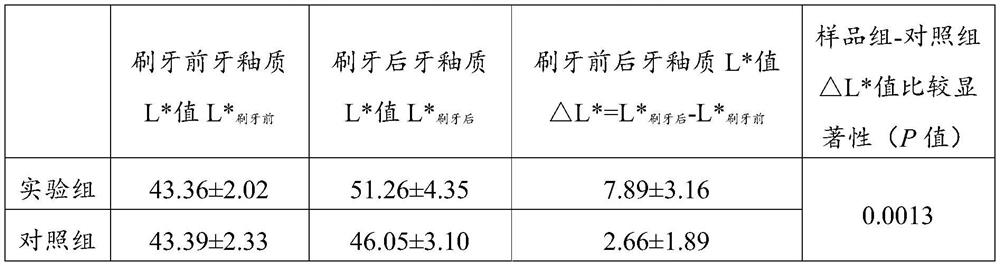

Image

Examples

Embodiment 1

[0029] 1. Raw and auxiliary materials: 200 parts of wormwood leaves, 100 parts of rosemary leaves;

[0030] The above two flavors were extracted twice with water, the first time was 8 times the amount of water (mass ratio), boiled and extracted for 1 hour, and the extract was collected; the second time, 6 times the amount of water (mass ratio) was added, boiled and extracted for 1 hour, collected Extracted solution, combined two extraction solutions, concentrated under reduced pressure at 50-60 °C to 1 times the amount of medicinal materials (mass ratio), added an equal amount of ethanol (mass ratio), and stirred while adding, after standing overnight, take the supernatant and stir. Add sodium hydroxide to adjust the pH value to 8.0-8.5, filter to obtain clear liquid, concentrate the clear liquid to 0.5 times the amount of mixed raw materials to obtain argyi leaves and rosemary leaf extracts (the soluble part of Qi yi rosemary perfume), and dry them into Solid, the solid yield...

Embodiment 2

[0069] By mass percentage, including 4% of mugwort and rosemary leaf extracts, 0.1% of potassium cinnamate, 0.4% of dipotassium glycyrrhizate, 1.5% of modified cellulose (hydroxyethyl cellulose and hydroxypropyl methylcellulose) The mass ratio is 3:2), friction agent includes hydroxyapatite 1% and walnut shell powder 10%, flavor includes menthol 0.4% and paeonol 0.3%, glycerin 20%, foaming agent 1.5% (thirteen Alketh-7 sodium carboxylate 0.5%, alkyl glycoside 0.5%, sodium laureth sulfate 0.25%, sodium lauroyl sarcosinate 0.25%), the balance is water (60.8%).

[0070] The preparation steps of this embodiment include:

[0071] (1) first get argyi leaves and rosemary leaves by mass ratio 4:1 to obtain mixed raw materials, add 7 times of water to the mixed raw materials, boil and extract for 1h for the first time, and collect the extract; add 7 times of mixed raw materials water, boil and extract for 1 hour for the second time, collect the extracts, combine the two extracts, and ...

Embodiment 3

[0077] By mass percentage, including argyi leaf and rosemary leaf extract 0.5%, potassium cinnamate 0.5%, dipotassium glycyrrhizate 0.1%, modified cellulose 0.5% (sodium carboxymethyl cellulose 0.1%, hydroxyethyl cellulose Vegetarian 0.2% and hydroxypropyl methylcellulose 0.2%), friction agent includes walnut shell powder 40%, flavor includes menthol 0.6% and paeonol 0.1%, glycerin 15%, foaming agent includes lauroyl sarcosine Sodium 0.5%, balance water (42.2%).

[0078] The preparation steps of this embodiment include:

[0079] (1) first get argyi leaves and rosemary leaves by mass ratio of 1:4 to obtain mixed raw materials, add 9 times the amount of water to the mixed raw materials, boil and extract for 1h for the first time, and collect the extract; add 5 times the amount of mixed raw materials water, boil and extract for 1 hour for the second time, collect the extracts, combine the two extracts, and then concentrate to 0.3 times the amount of the mixed raw materials, add ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com