Burning-resistant firework flaming cylinder

A flamethrower and fireworks technology, which is applied to fireworks, offensive equipment, weapon types, etc., can solve the problem that the launcher is not resistant to high temperature burning for a long time, and achieve the effects of reducing smoke pollution, high structural strength and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Embodiment 1: the cylinder body and the fire port of the scorching-resistant fireworks flame-throwing tube are an integrated structure of molding; the raw materials of the molding include the following components by weight: 50 parts of soil, 4 parts of water, 37 parts of phenolic resin, 18 parts of polyvinyl alcohol, and 8 parts of natural resin.

[0023] Among the above components, the soil is dried and pulverized into powder, such as 80-120 mesh. Then dry mix with other components evenly, add water while stirring and mix evenly to form a billet, put the billet into the mold under normal temperature pressure molding, demould to get the finished product. Pressurization can use pressurized equipment, such as a 2-ton hydraulic press. The finished product of the fireworks torch can be applied to the fireworks.

Embodiment 2-7

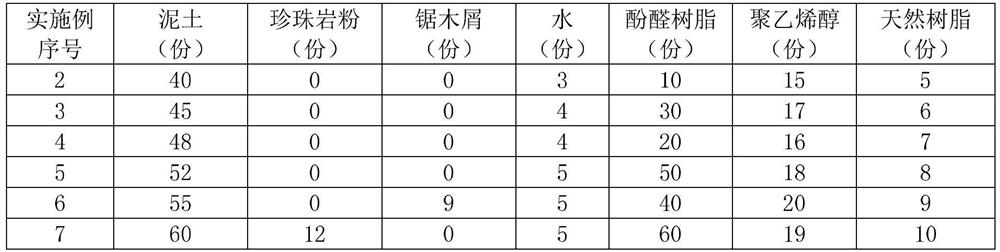

[0024] Embodiment 2-7: the difference from embodiment 1 is that the components and weight ratios of the raw materials of compression molding are different, as shown in the following table:

[0025]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap