Temperature control and noise reduction system for high-power laser projector

A laser projector, high-power technology, applied in instruments, optics, projection devices, etc., can solve problems such as affecting user experience, generating noise, and increasing fan speed, improving heat dissipation performance, reducing noise, and reducing volume. the effect of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

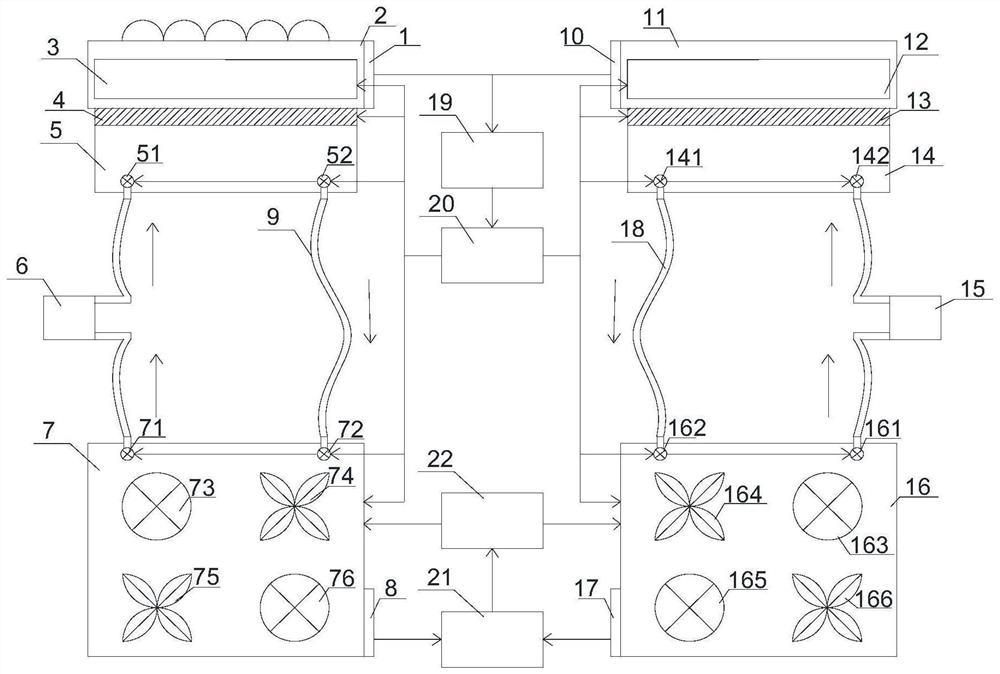

[0051] like figure 1 As shown, a temperature control and noise reduction system for a high-power laser projector disclosed in this embodiment includes a laser head 2, a temperature control and noise reduction system I for temperature control and noise reduction for the laser head 2, a DMD chip 11, and a Temperature control and noise reduction system II for temperature control and noise reduction of DMD chip 11.

[0052] The temperature control and noise reduction system I includes a first liquid spray cooling device 3, a first thermoelectric refrigeration device 4, a heat dissipation circulation system I, a temperature induction control system I and a sound induction control system I.

[0053] The first liquid spray cooling device 3 is fixedly arranged above the laser head 2. The first liquid spray cooling device 3 includes a spray device, a heat exchanger and a circulating pump. The vaporized cooling liquid is sprayed onto the laser head 3, and vaporizes after absorbing the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com