Silicon optical chip design method capable of automatically controlling temperature

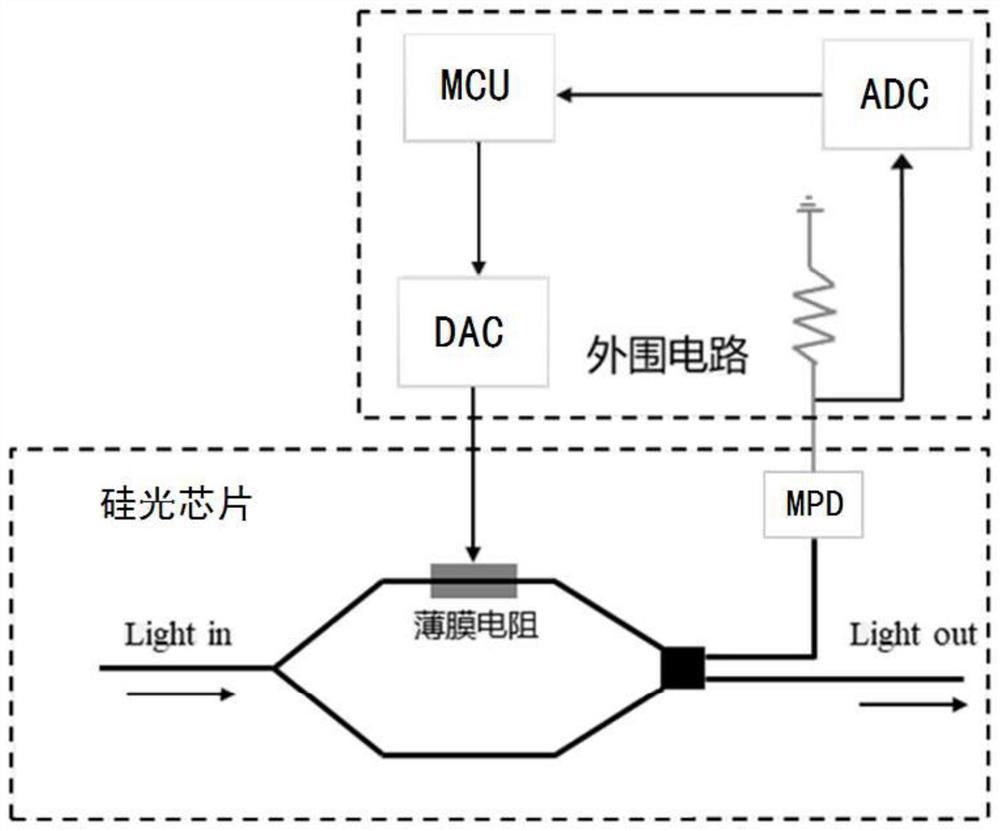

A silicon photonics chip and design method technology, applied in temperature control, control/regulation system, non-electric variable control, etc., can solve the problems of reduced yield rate of silicon photonics chip, increased cost, and reduced advantages of high integration of silicon photonics chip , to achieve the effect of cost reduction, reduction of defective rate, and reduction of control components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

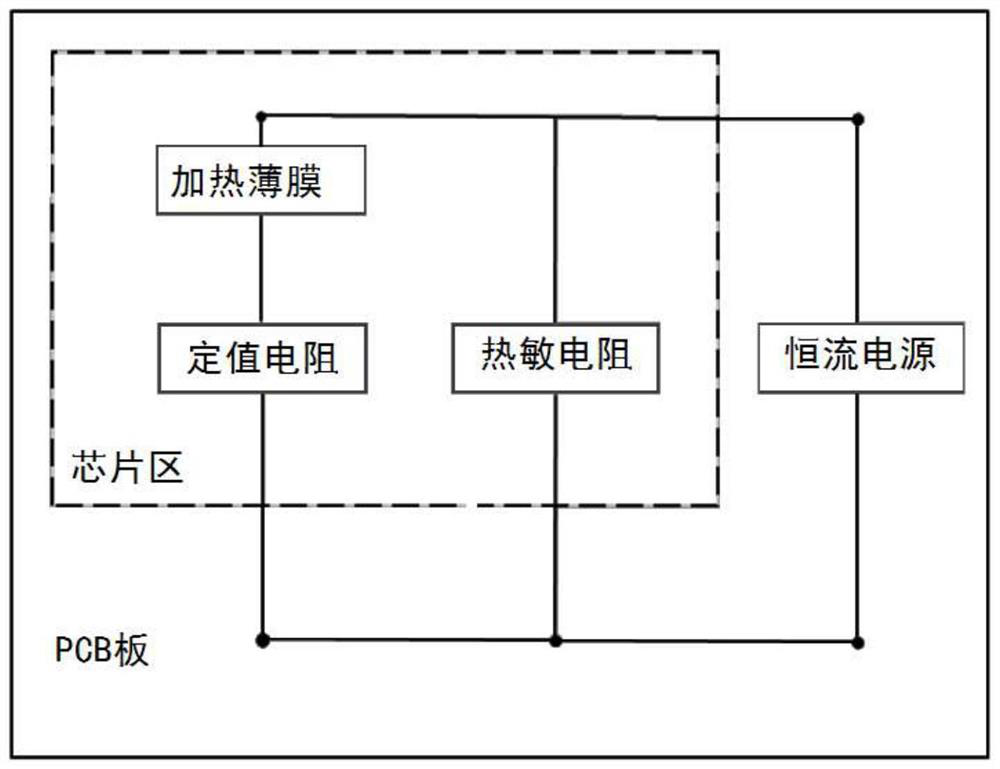

[0060] like image 3 As shown in the figure, a thin film heating resistor is deposited above the silicon photonics device inside the chip, and a fixed-value resistor is connected in series inside the chip and then connected in parallel with the thermistor, which is exported to the pad on the PCB through the gold wire, and is connected to the constant current power chip. The other end is grounded, which refers to the negative electrode of the constant current power supply chip. Usually, the negative electrode of the constant current power supply chip is the same end as the ground end of the entire PCB. In this embodiment, the thermistor is arranged on the silicon photonics chip, and the connection and fixation of the thermistor is realized by arranging pads on the silicon photonics chip, and then the two ends of the thermistor are respectively connected with the constant current power supply chip. Two-pole connection.

Embodiment 2

[0062] like Figure 4 As shown, the same as Embodiment 1, the difference is that the resistor connected in series with the thin film heating resistor is welded on the PCB outside the chip, and is connected to the chip area through a gold wire, and the resistor can be adjusted according to the situation. Figure 4 Among them, 1 is a chip, 2 is a film heating resistor, 3 is a thermistor, 4 is an adjustable resistor, 5 is a constant current power supply, and 6 is a PCB board.

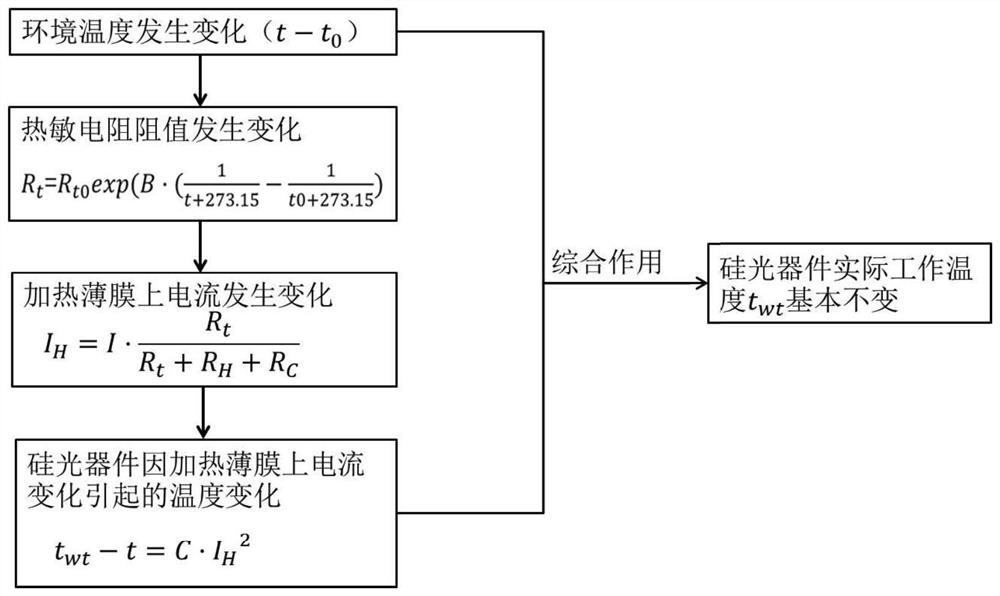

[0063] The feasibility of the above embodiments is analyzed below.

[0064] Taking the silicon photonics Mach-Zehnder Interferometer (MZI) as an example for analysis, this structure is widely used in various silicon photonics devices, including modulators, filters, optical switches, attenuators and so on.

[0065] For a silicon-optical MZI interferometer, the transfer function is:

[0066] I 0 / I i =0.5×[1+cos(βΔL)]

[0067] Among them, β=2πn eff / λ is the propagation constant of the silicon optical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com