Plunger pair seal gap automatic compensation verification test device

A technology of automatic compensation and sealing gap, applied in the field of hydraulic components, can solve the problem that the compensation effect cannot be measured separately, and achieve the effect of low processing and testing cost, less control components, and safe weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

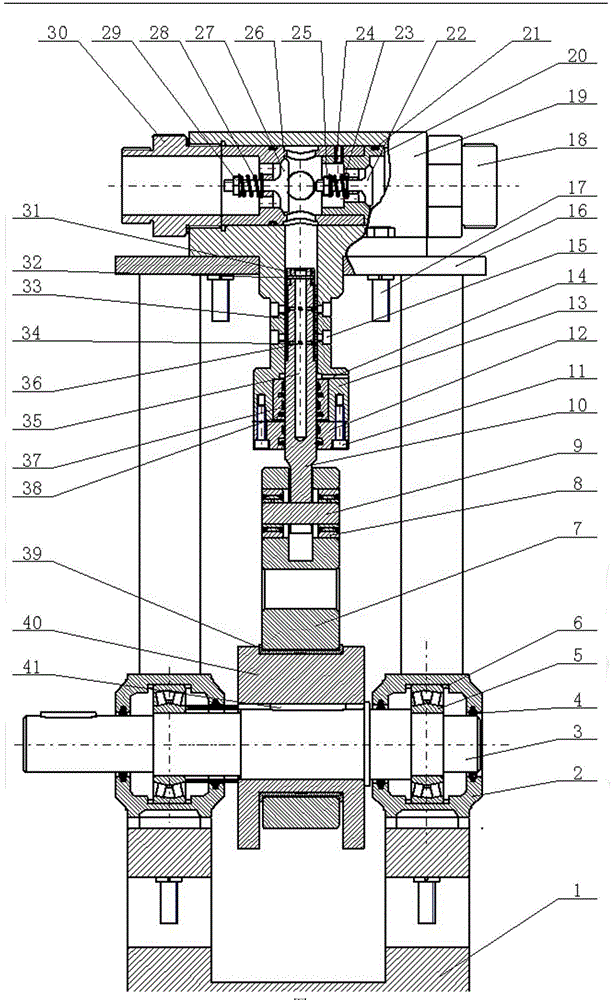

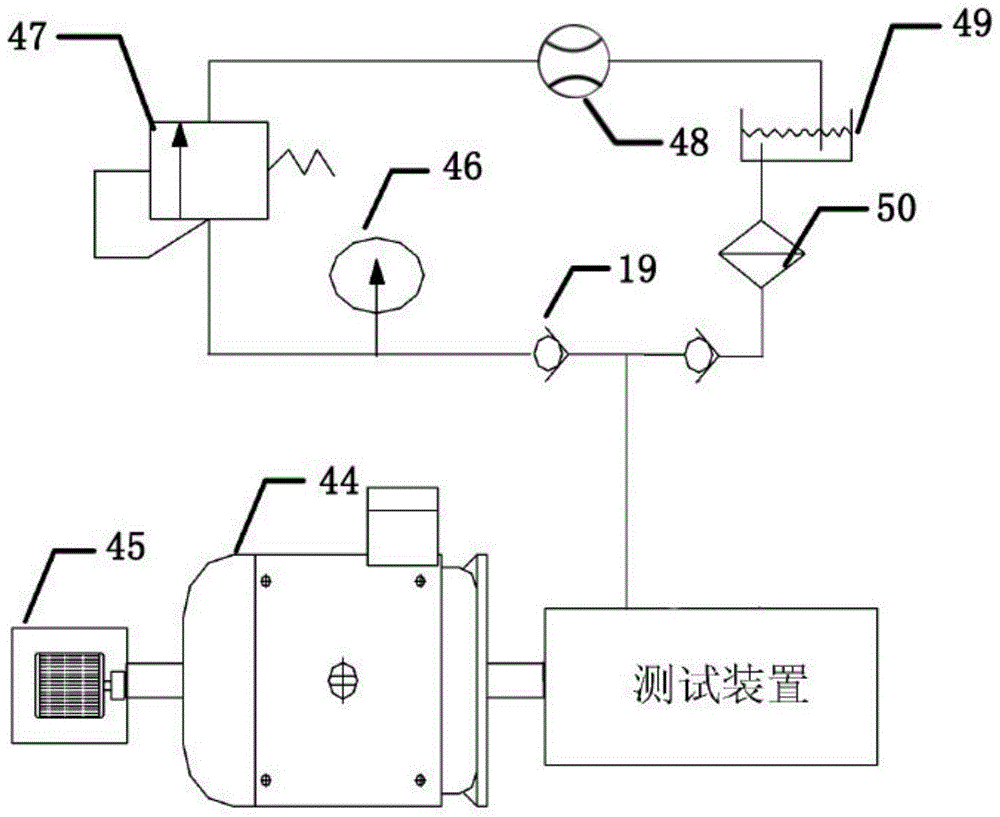

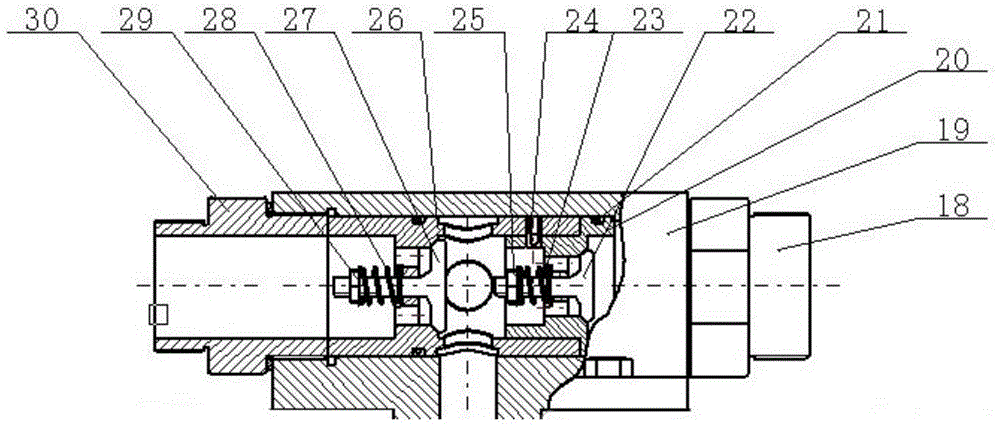

[0030] Such as Figure 1-5 As shown, the automatic compensation verification test device for the plunger pair seal gap, the device includes the device housing bracket 1 and two bearing seats 2, the central shaft 3, the eccentric wheel 40, the bearing bush 39, the connecting rod 7, the plunger pin 9, the column Plug roller 8, plunger cylinder 13, cylinder end cover 12, sealing ring 38, eddy current sensor 15, micro flow meter 14.

[0031]The central axis 3 is fixed on the housing support 1 through two bearing supports 2, and the two bearing supports 2 are respectively fixed on the horizontal beam of the device housing 1, and the central axis 3 is located in the middle part between the two bearing supports 2 The flat key 41 is fixedly connected with the eccentric wheel 40, the outer surface of the eccentric wheel 40 is tightly wrapped by two ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com