3D Micro/Nano Measuring Probe

A measurement probe, micro-nano technology, applied in the direction of measuring devices, instruments, optical devices, etc., can solve the problems of low sensitivity and precision of strain gauge detection, easy fracture of silicon film structure, uneven stress distribution, etc., and achieve convenient manual adjustment , low cost, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

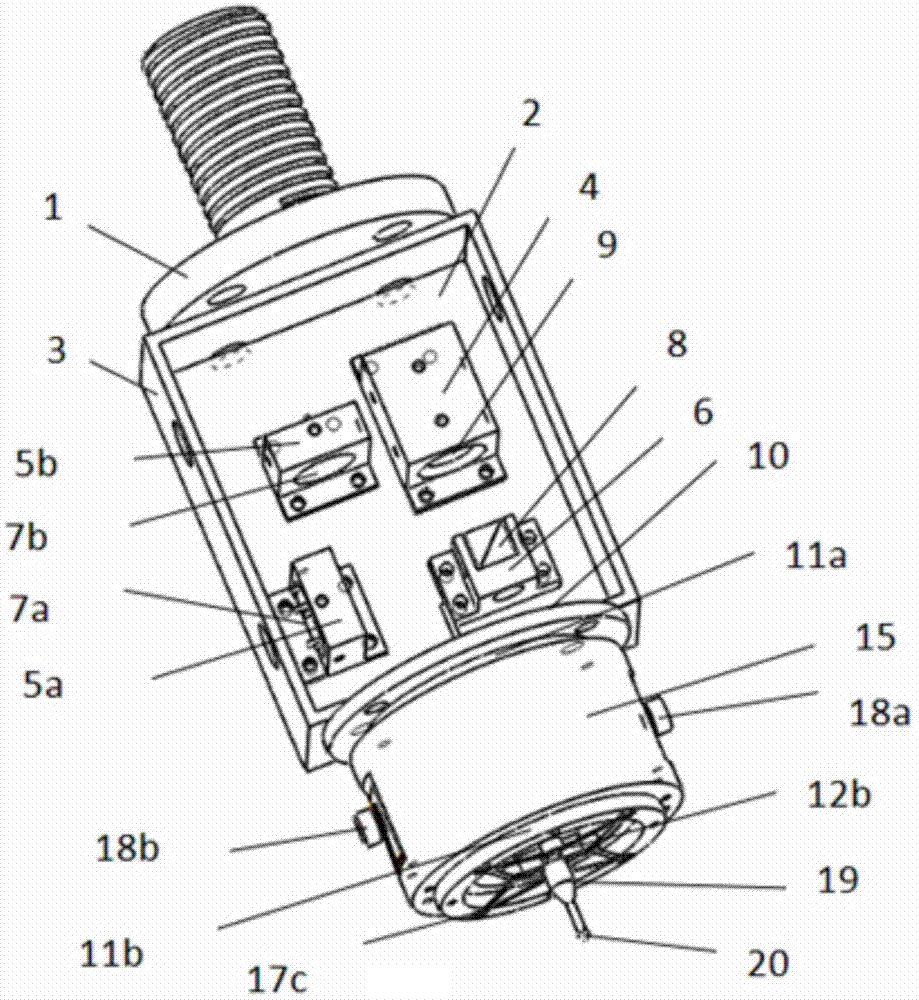

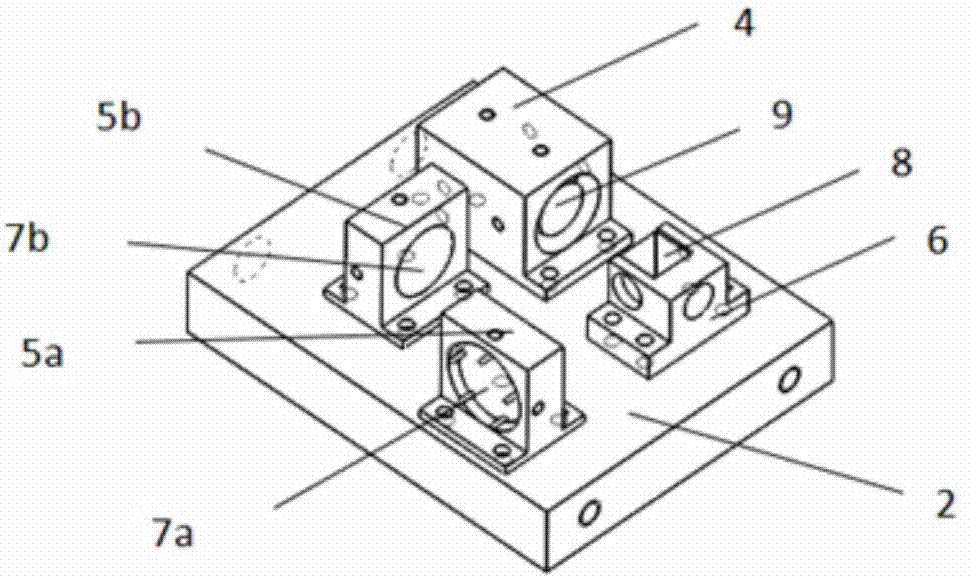

[0029] see figure 1 In this embodiment, the three-dimensional micro-nano measurement probe is fixedly connected to the probe unit and the internal measurement unit by means of a support.

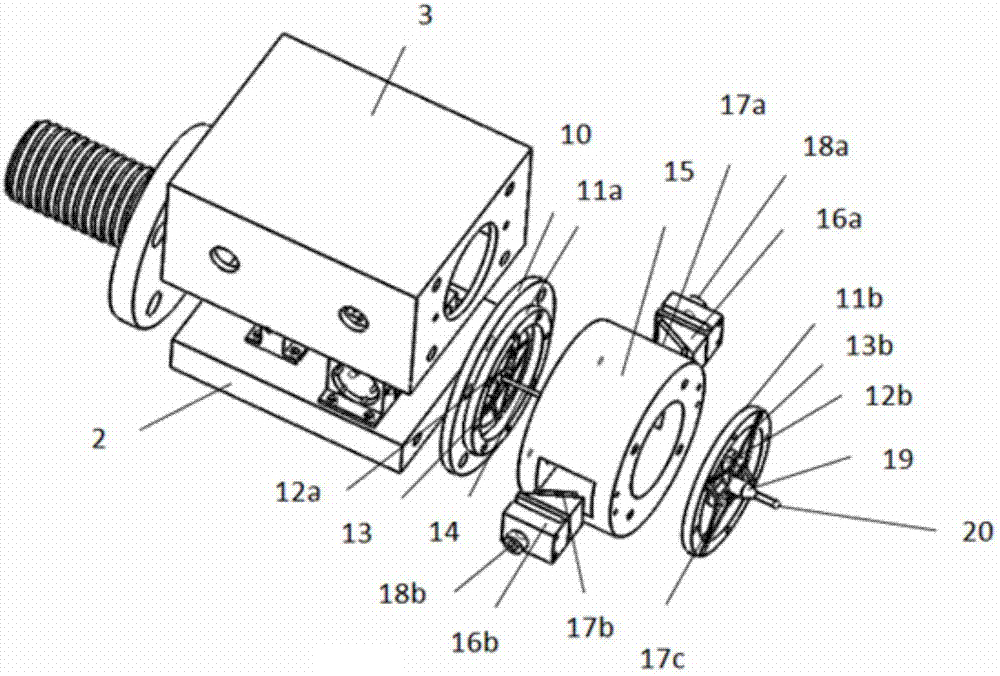

[0030] see figure 2 , Figure 6 and Figure 7, the measuring head unit is fixed on the front end surface of the hollow cylinder 15 with the front end ring 11b, and the four front end "V" shaped reeds 13b are connected one by one with the vertices of the front "V" shaped reeds 13b. The arm ends of each cantilever of the sheet 12b, the two feet of the front end "V" shaped reed 13b are connected to the end face of the front end ring 11b; The central position of the front end cross suspension plate 12b is fixedly provided with a central plane reflector 17c, and a probe 19 is installed on the cross suspension plate 12b toward the outside of the hollow cylinder, and the front end of the probe 19 has a ruby measuring ball 20; The end face of the tail part of the tube 15 is fixedly provided w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com