Electromagnetic switch

An electromagnetic switch and cover technology, which is applied in the field of electromagnetic switches, can solve the problems of increased motor insecurity and maintenance costs, failure of electromagnetic switch contacts, and failure of motors to work normally, achieving simple structure, reliable performance, and prevention of overheating. The effect of early failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

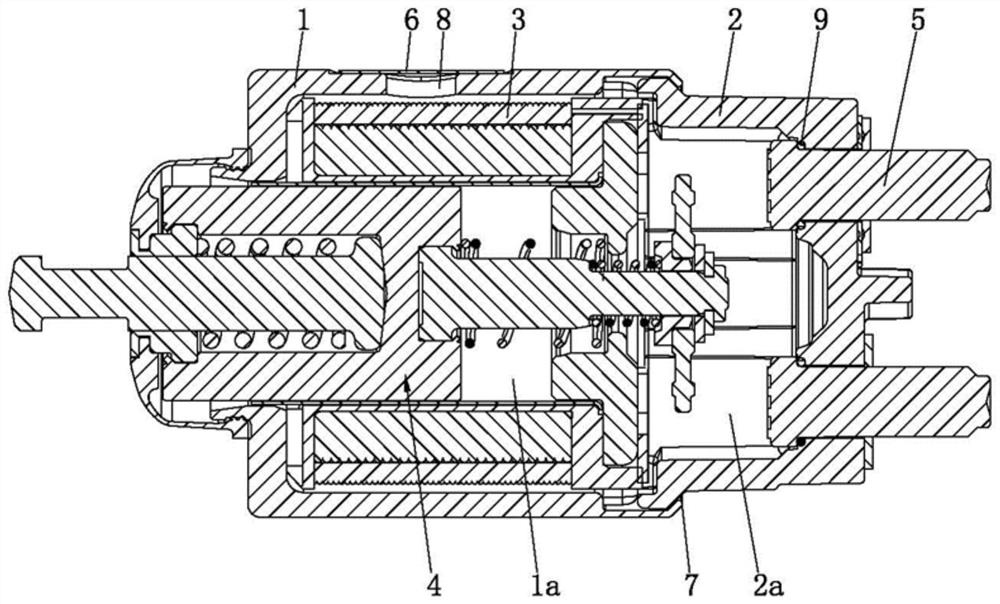

[0017] The present invention will be described in further detail below with reference to the accompanying drawings and specific embodiments.

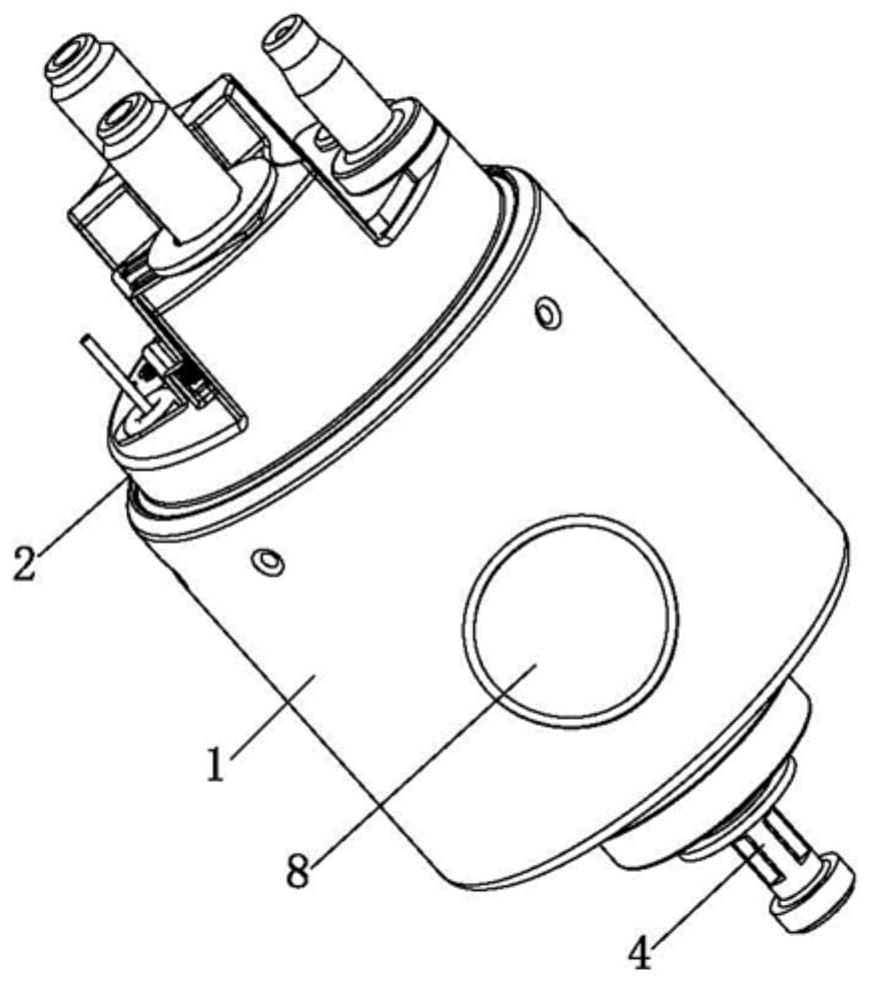

[0018] An electromagnetic switch, including a cover 1, an end cover 2, a coil assembly 3, a coil bobbin 4b, a moving iron core assembly 4, a static contact 5, a water-permeable component 6, and a sealing layer 7. The relationship between them is explained in detail:

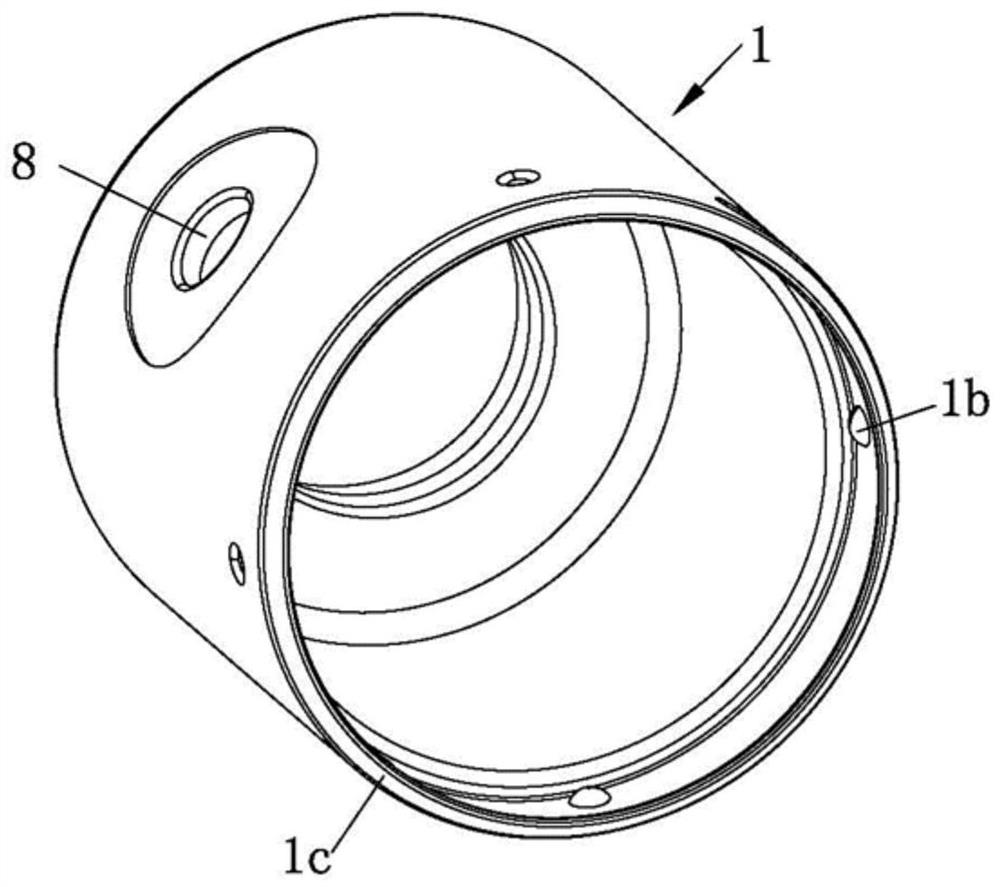

[0019] The cover 1 has an axial first stepped through hole, and the end cover 2 is provided with a cavity 2a. After one end of the cover 1 is combined and fixed with one end of the end cover 2, a first step is formed between the cover 1 and the end cover 2 The accommodating cavity 1a, the first accommodating cavity 1a is used for accommodating at least a part of the coil assembly 3 , the movable iron core assembly 4 and the static contact 5 .

[0020] As mentioned, the end cover 2 is made of ammonia-free thermosetting plastic, which can withstand high and low temperature,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com