Manufacturing method of quantum well optical detector and quantum well optical detector

A technology of optical detectors and manufacturing methods, which can be applied to semiconductor devices, electrical components, circuits, etc., and can solve the problems of low short-wave infrared responsivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0068] The fabrication method of the quantum well photodetector in this embodiment includes the following processes:

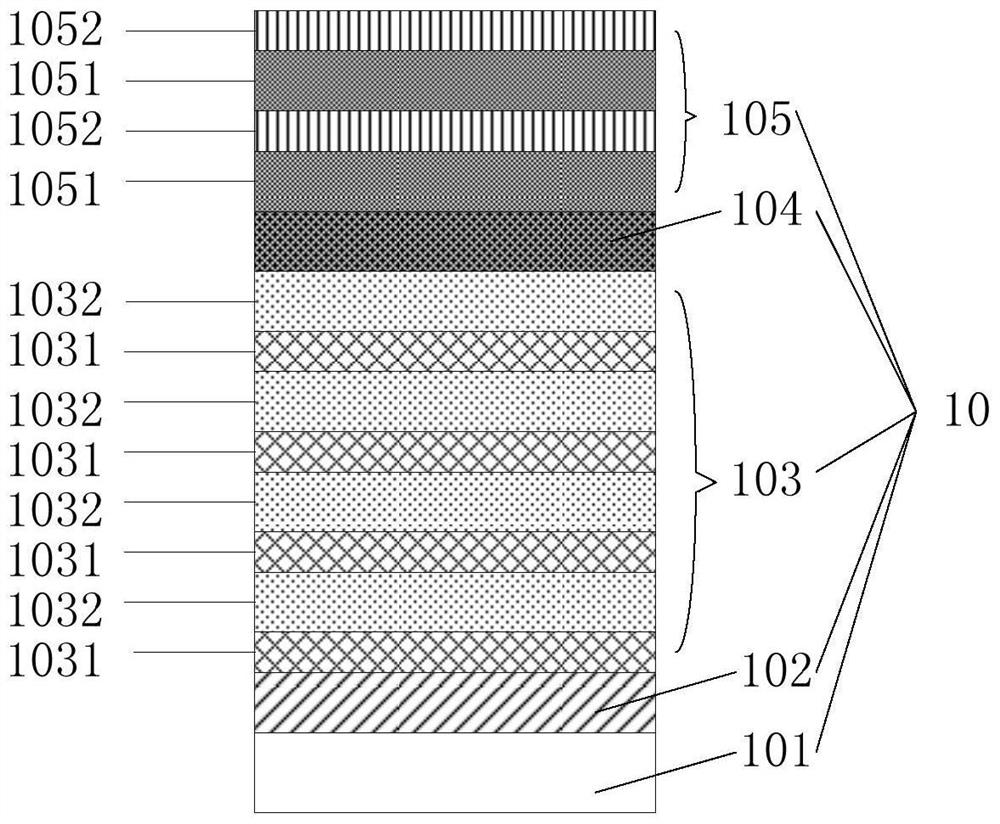

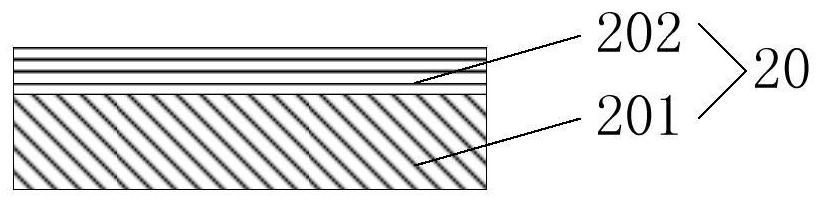

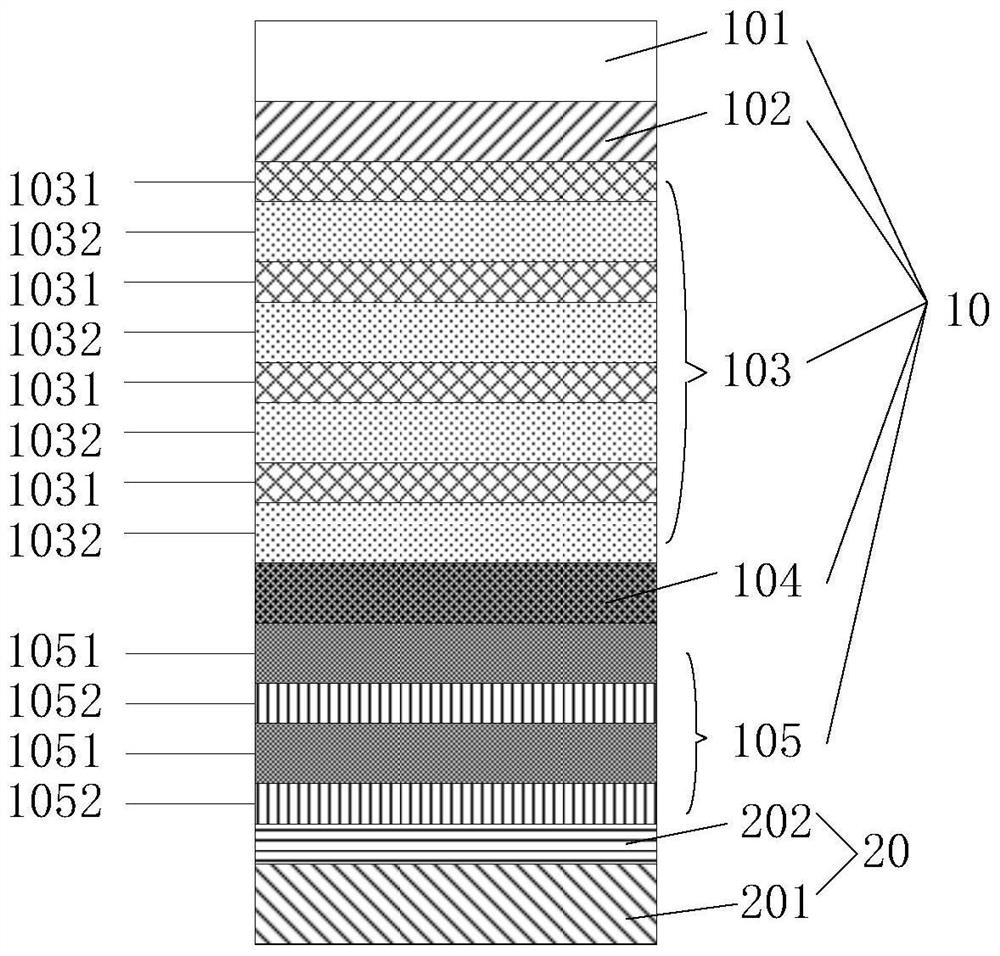

[0069] like Figure 5 As shown, the acceptor substrate 10 is provided, and the acceptor substrate 10 includes a first substrate layer 101, a second Ge buffer layer 107, a first Ge buffer layer 102, a Ge buffer layer 107 and a Ge x Si 1-x / Ge multiple quantum well layer 103, P-type Ge layer 104 and cavity structure 105, the above-mentioned Ge x Si 1-x / Ge multiple quantum well layer 103 includes alternately arranged Ge x Si 1-x Layer 1031 and Ge layer 1032, wherein x is greater than 0.75 and less than or equal to 1, and the above resonant cavity structure 105 includes alternately arranged silicide material layers 1051 and first Al 2 O 3 layer 1052;

[0070] The first substrate layer, the first Ge buffer layer, and the Ge are prepared by a rapid thermal chemical vapor deposition method x Si 1-x The / Ge multiple quantum well layer and the above-mentioned...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com