High-speed permanent magnet motor with novel rotor structure

A rotor structure, permanent magnet motor technology, applied in the direction of magnetic circuit shape/style/structure, magnetic circuit, electromechanical devices, etc., can solve the problems of weakening strength and increasing magnetic flux leakage, meeting mechanical strength and reducing rotor eddy current. loss, the effect of tight motor structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to realize the technical method of the present invention and make its purpose and performance easy to understand, the invention is further described below with reference to the specific embodiments.

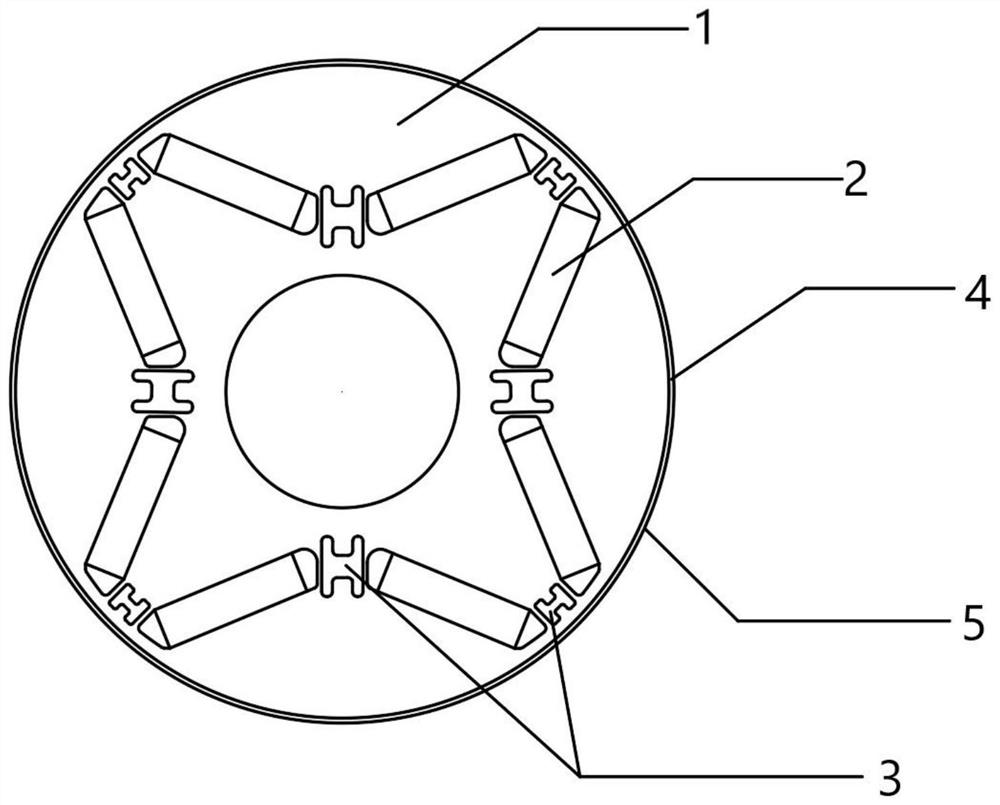

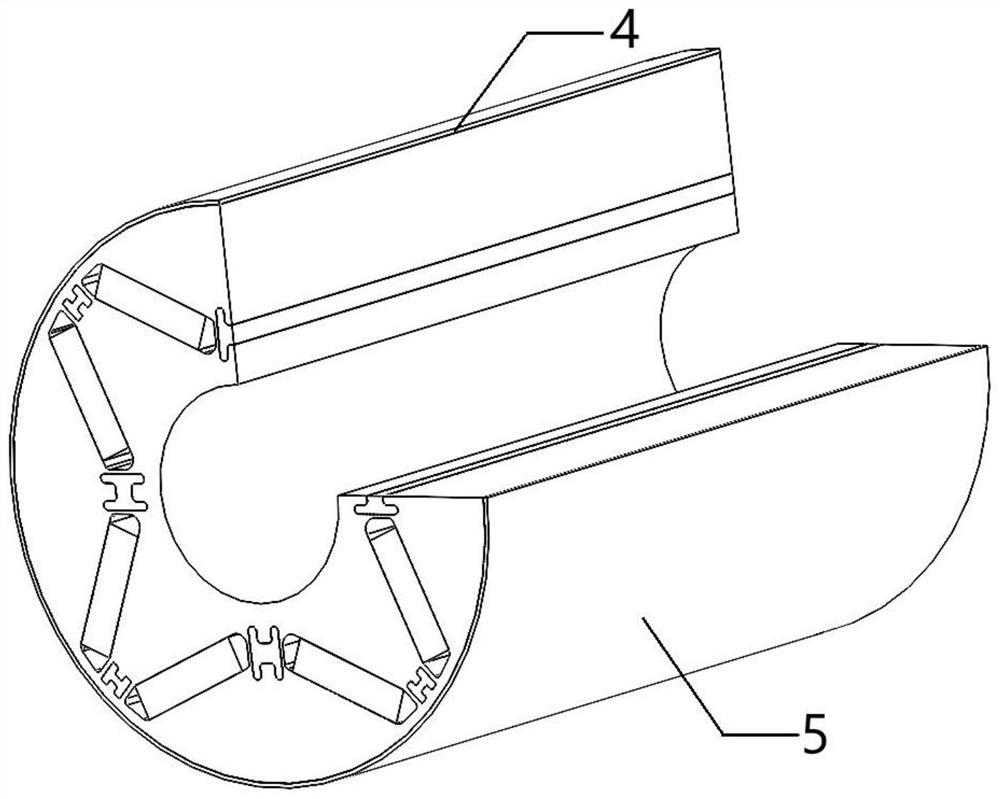

[0018] see description attached figure 1 and attached figure 2 , a new type of high-speed synchronous permanent magnet motor with rotor structure, which is characterized in that: the magnetic rib on the side of the main magnetic isolation bridge and the auxiliary magnetic isolation bridge are embedded with "H" type reinforcing ribs 3, and the carbon fiber material sheath 4 is closely attached Built-in motor rotor surface.

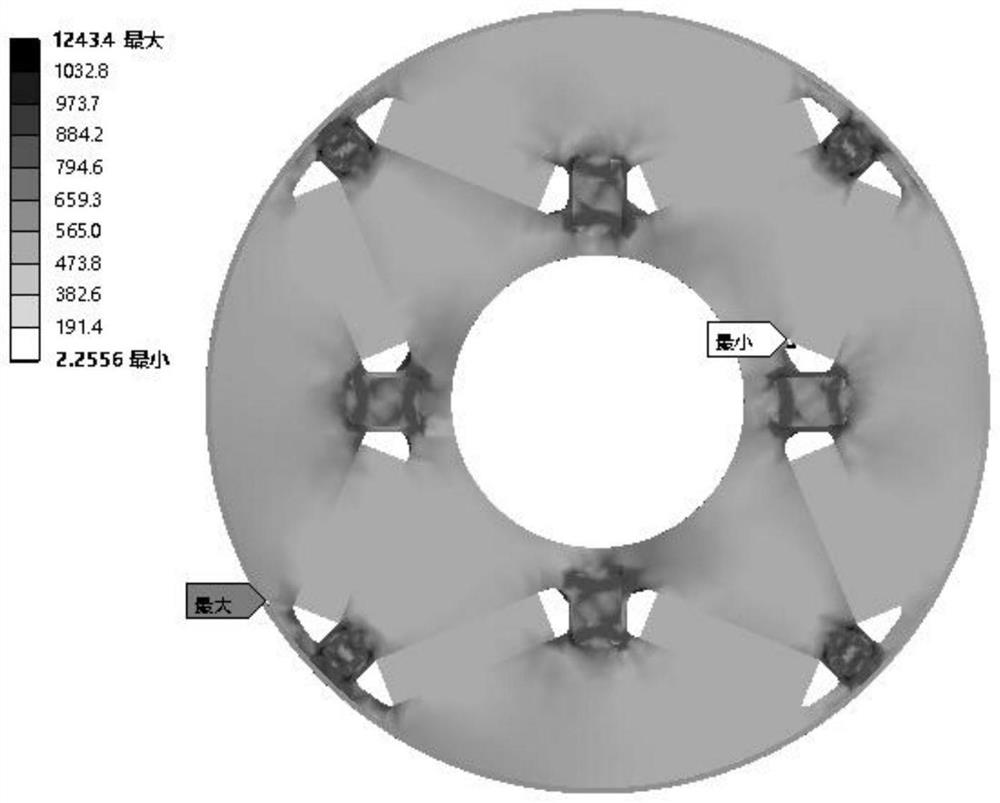

[0019] In this implementation, the permanent magnets are 4 poles (2 pairs of poles), and at the same time, "H"-shaped reinforcing ribs 3 are embedded in the positions of the main magnetic isolation bridge side magnetic rib and the auxiliary magnetic isolation bridge, which changes the traditional reinforcement used in built-in motors. The ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com