New energy intelligent driving motor cooling system

A technology for driving motors and cooling systems, applied in cooling/ventilation devices, electromechanical devices, electrical components, etc., can solve the problems of poor heat dissipation effect of disc motors, and the temperature of winding coils cannot be well cooled, so as to improve the heat dissipation effect, The effect of preventing water overflow and reducing flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

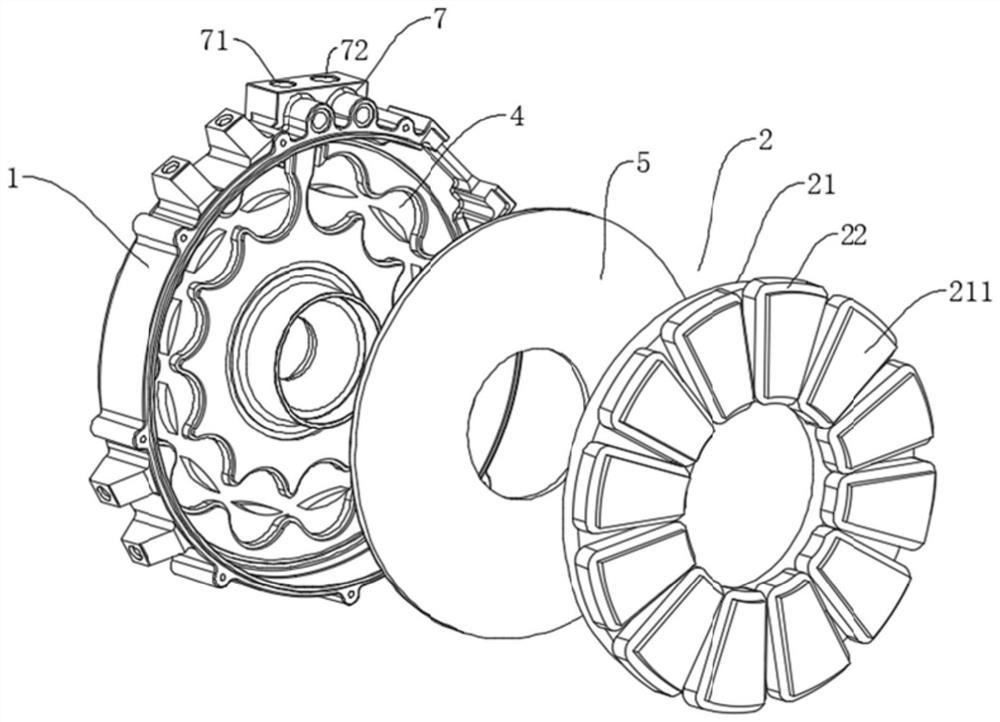

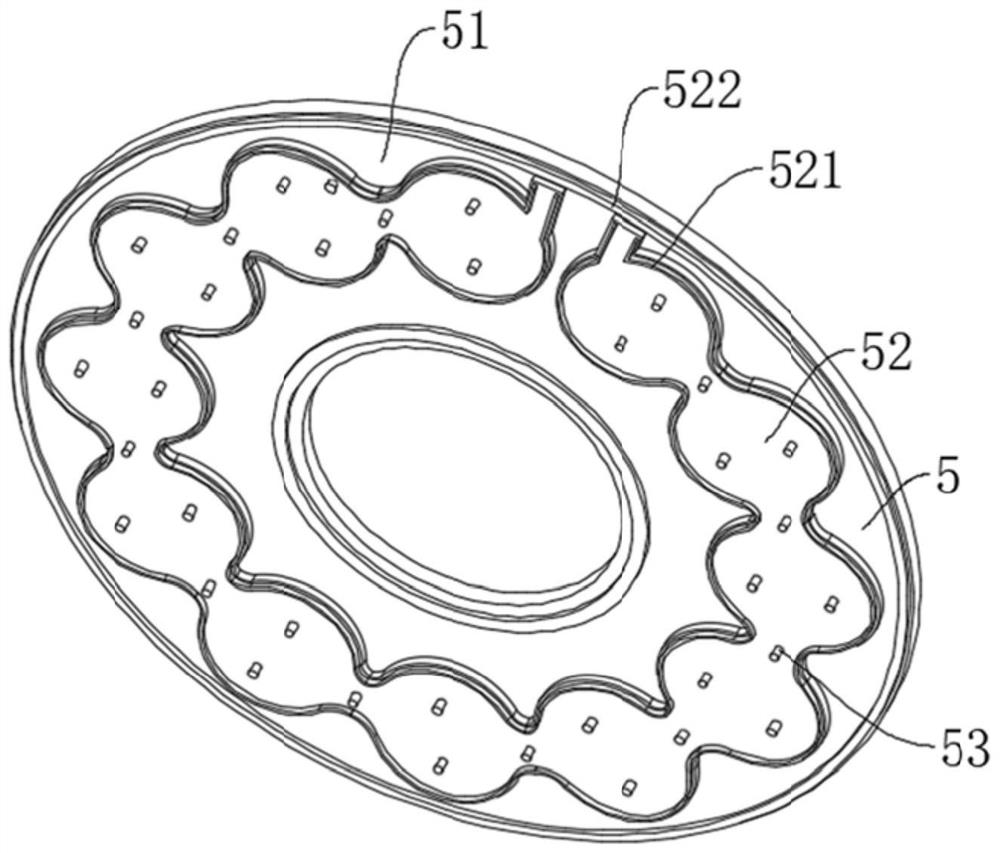

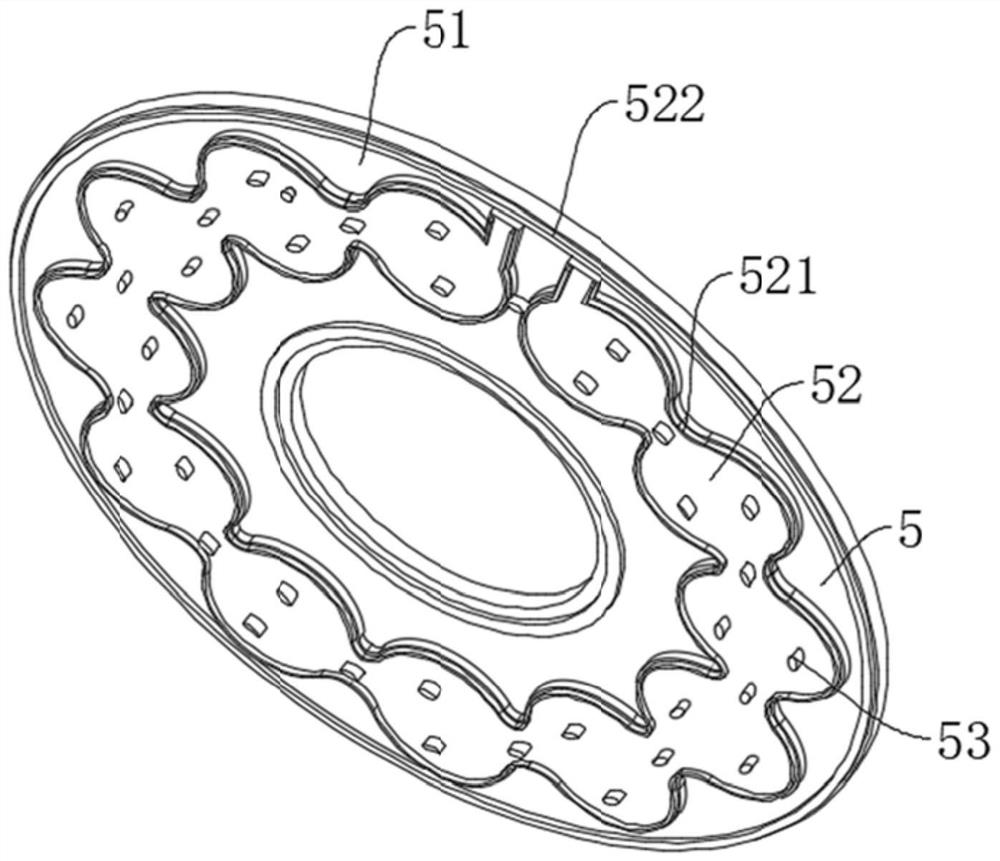

[0029] like Figure 1-6 As shown, a new energy intelligent drive motor cooling system includes a water-cooled end cover 1 and a high thermal conductivity stator assembly 2, the high thermal conductivity stator assembly 2 is fixed in the water-cooled end cover 1, and the high thermal conductivity stator assembly 2 It includes a stator iron core 21, a winding coil 22, and a sealing and heat-conducting mechanism 5. The surface of the stator iron core 21 is arrayed with a number of stator iron core teeth 211 along the circumferential direction, and the winding coil 22 is installed on the stator iron core. On the tooth portion 211, the sealed heat conduction mechanism 5 is provided between the water-cooled end cover 1 and the stator core 21, and a cooling circuit 4 is arranged inside the water-cooled end cover 1; the cooling circuit 4 corresponds to each Each of the back positions of the winding coils 22 is provided with a strong heat exchange area 43, and a cooling liquid connecti...

Embodiment 2

[0034] like Figure 4 The difference from the above-mentioned first embodiment is that the heat dissipation block 53 is elliptical, and the long axis direction of the ellipse is consistent with the flow direction of the cooling water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com