Rotating speed control method and synchronous motor for automobile air conditioner compressor

A synchronous motor and speed control technology, which is applied in the direction of controlling generators, electromechanical brakes, and electromechanical transmissions, can solve the problems of synchronous motor speed fluctuations, damage to compressor winding excitation devices, and inability to install speed sensors. The effect of out-of-step state, suppression of speed fluctuation, and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

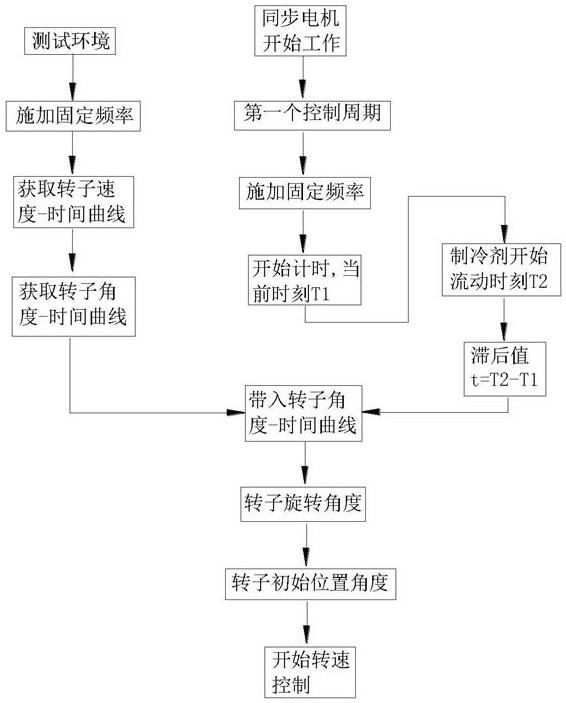

[0031] The technical solutions in the embodiments of the present invention will be clearly and completely described below with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only a part of the embodiments of the present invention, rather than all the embodiments.

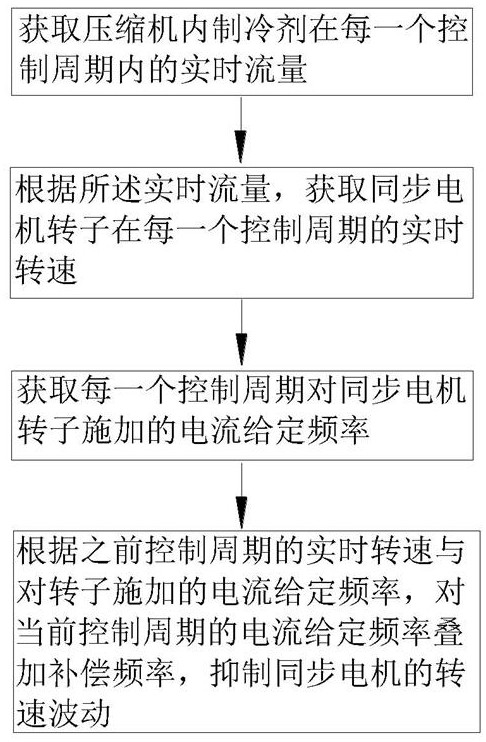

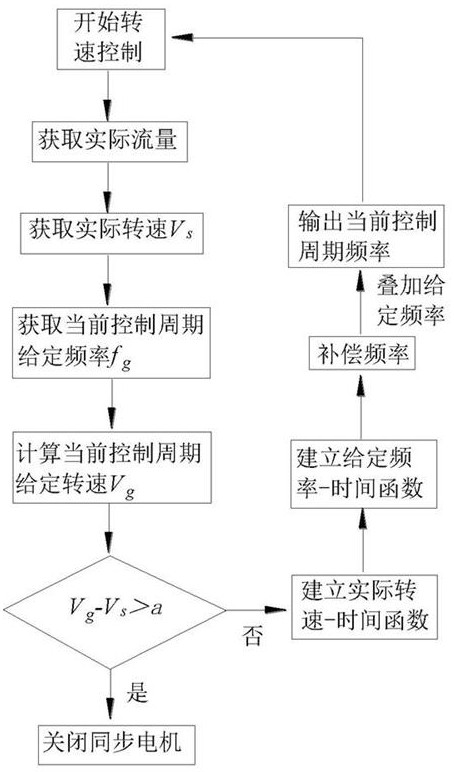

[0032] like figure 1 As shown: a speed control method, comprising the following steps:

[0033] Obtain the actual flow of refrigerant in the compressor in each control cycle;

[0034] According to the actual flow, the actual speed of the rotor of the synchronous motor in each control cycle is obtained, and the relationship function between the actual speed and time is established;

[0035] Obtain the given frequency of the current applied to the rotor of the synchronous motor in each control cycle, and establish a given frequency-time relationship function;

[0036] According to the relationship function between actual speed and time and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com