Flue gas desulfurization and denitrification purification and emission device and flue gas comprehensive treatment system

A technology of desulfurization, denitrification and discharge device, which is applied in the field of flue gas purification, can solve the problems of waste of absorbing liquid resources, stirring of absorbing liquid, and inability to use absorbing liquid, etc., and achieves the effect of realizing pollution-free discharge and speeding up fluidity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

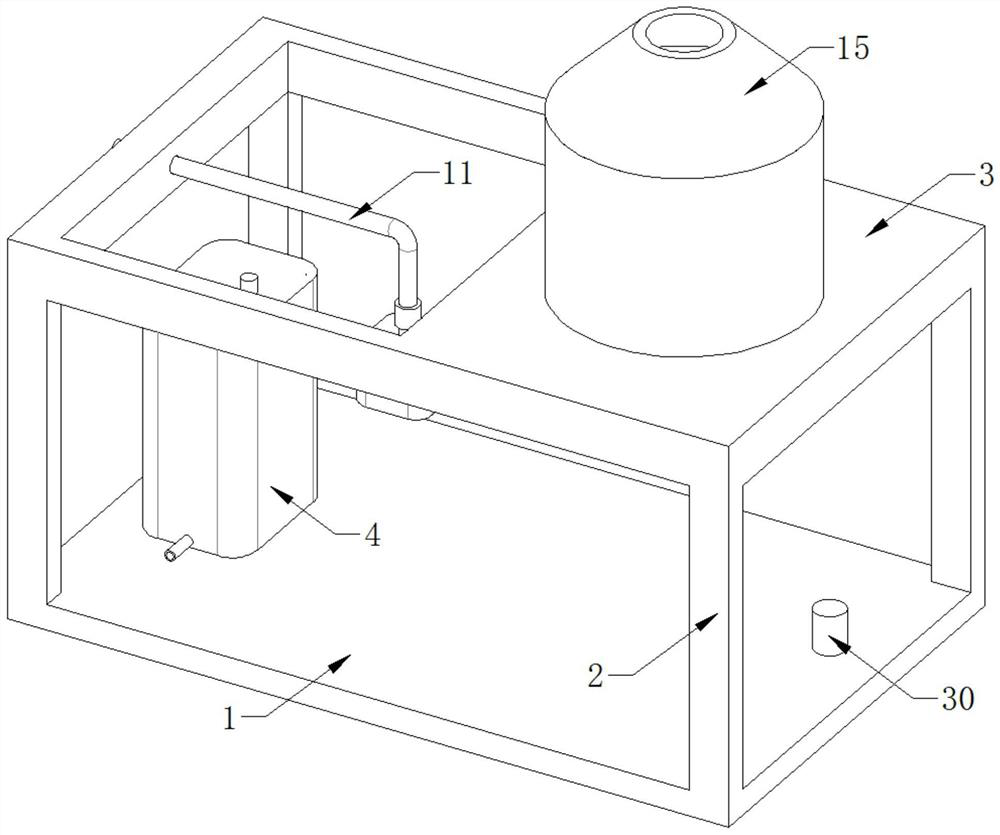

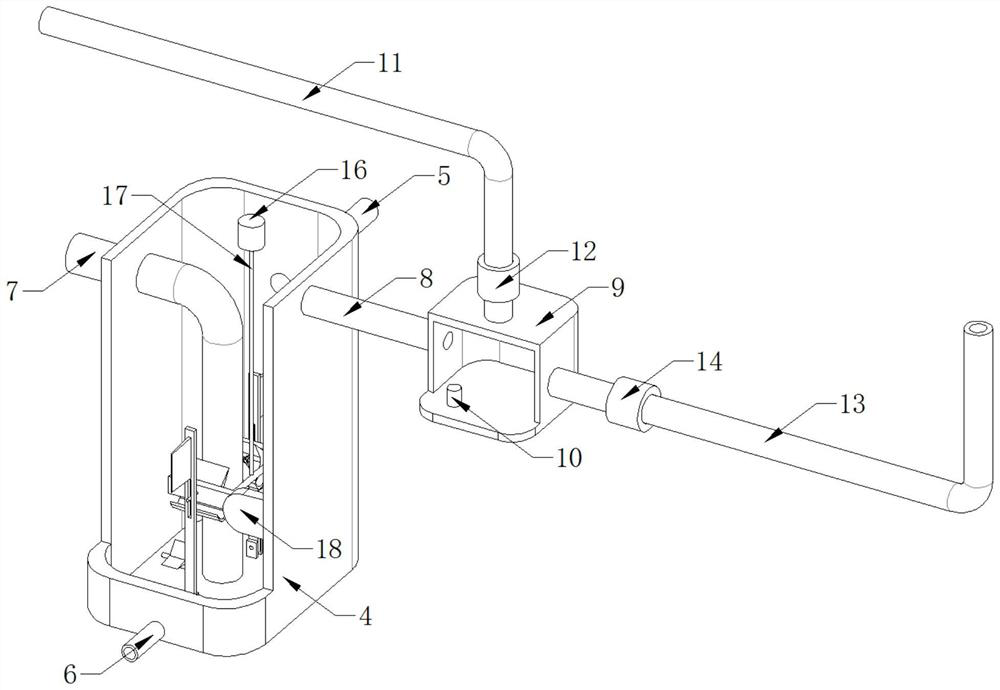

[0036] 3. See Figure 1-5 , A purification and emission device for flue gas desulfurization and denitrification, comprising a bottom plate 1, a support leg 2 is fixedly installed at the four corners of the top side of the bottom plate 1, a top plate 3 is fixedly installed on the top side of the support leg 2, and an exhaust tower is fixedly installed on the top side of the top plate 3 15, a reactor 4 is fixedly installed on the top side of the bottom plate 1, the interior of the reactor 4 is filled with sodium hydroxide absorbing liquid, and one side of the reactor 4 is provided with a gas delivery mechanism, and the gas delivery mechanism is used to transport the absorbed flue gas;

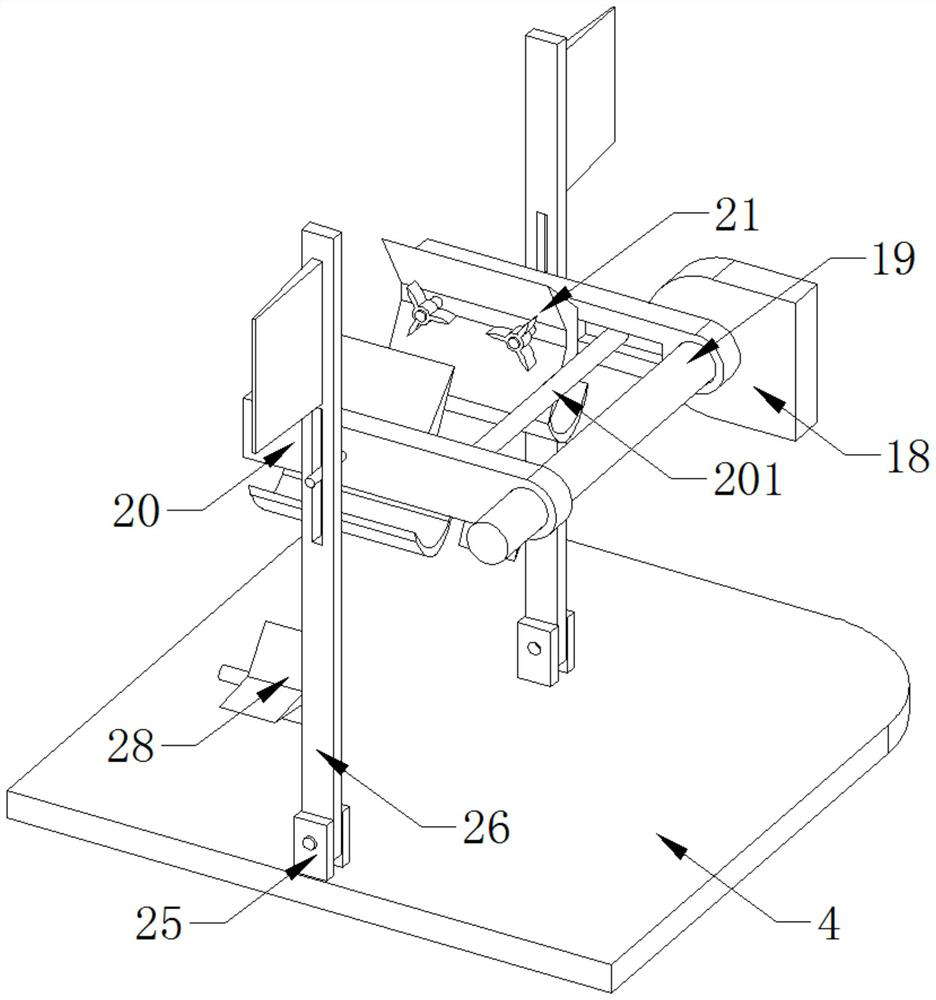

[0037] The top side of the reactor 4 is provided with a telescopic mechanism, the inner wall of the reactor 4 is provided with a support mechanism, and the bottom inner wall of the reactor 4 is provided with a shaking mechanism, and the telescopic mechanism drives the shaking mechanism to shake th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com