Special heat insulation film net for keeping activity of tea leaves through nanotechnology

A nanotechnology, tea leaf technology, applied in the field of agricultural planting equipment, can solve the problems of the tea tree environment is too cold, the manufacturing cost of the reflective film is high, and the amount of light is uncertain, and the effect of reducing temperature and light weight is achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

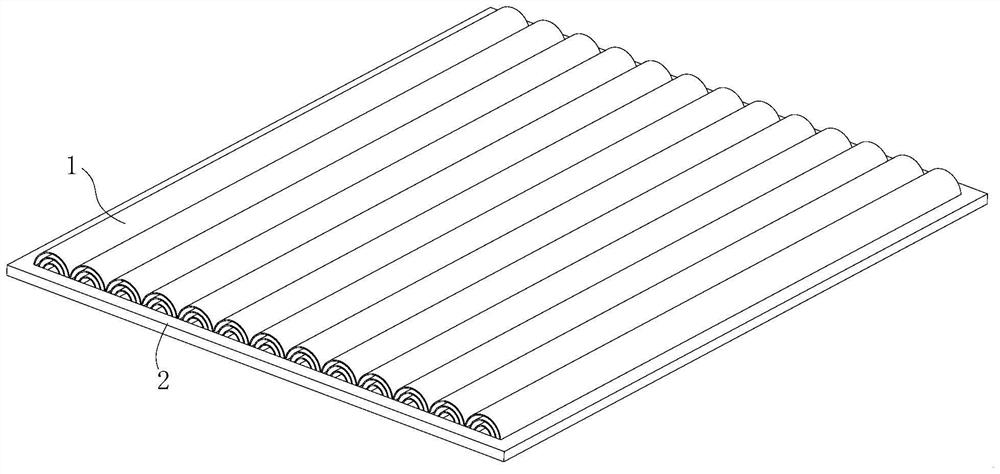

[0038] Specific embodiment 1: please refer to Figure 1-6 A special heat-shielding film net that maintains the activity of tea leaves by nanotechnology, including a plurality of meshes 1 and fixed edges 2 arranged in parallel; the adjacent meshes 1 are closely attached to form a mesh surface; the axis of the meshes 1 It is always perpendicular to the direction of sunlight irradiation, that is, assuming that the sun rises in the east and sets in the west, the meshes 1 in this embodiment are all arranged in a north-south direction.

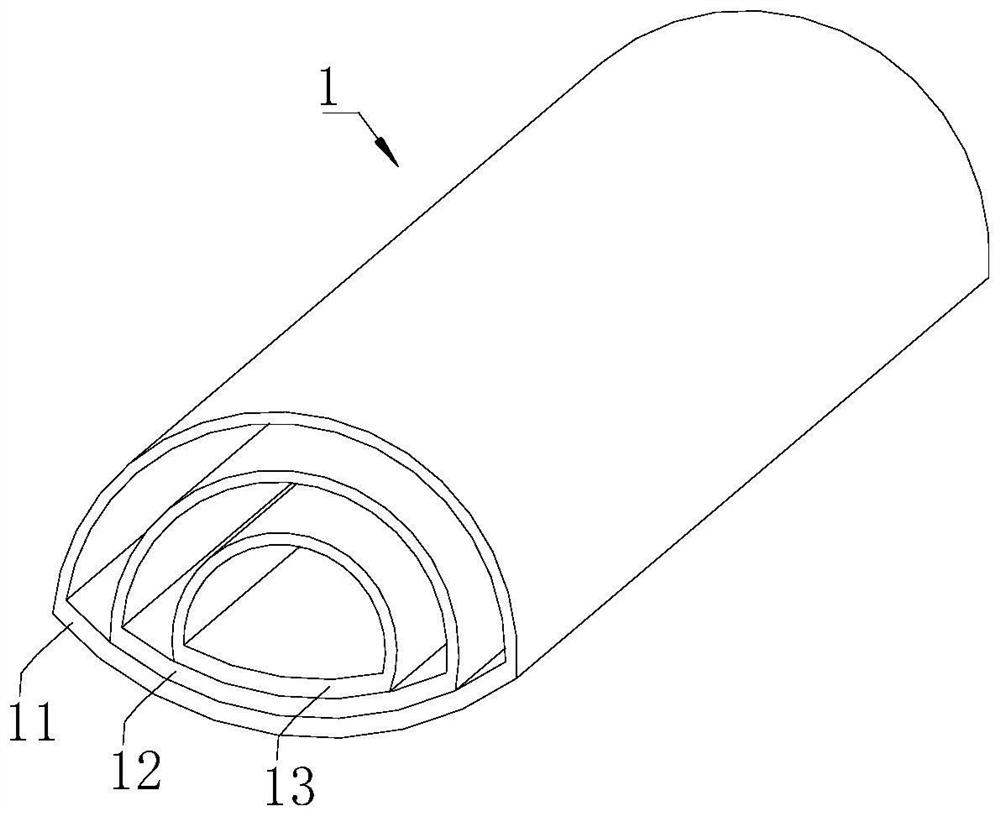

[0039]The mesh 1 includes a plurality of wire tubes distributed from the inside to the outer layer; in this embodiment, the wire tubes are divided into an outer wire tube 11, a middle wire tube 12 and an inner wire tube 13; the outer wire tube 11, the middle wire tube 12 and the inner wire tube 13; The inner wire tube 13 is a component with the same structure but different dimensions, and the size is reduced in equal proportions, and the outer wire ...

specific Embodiment 2

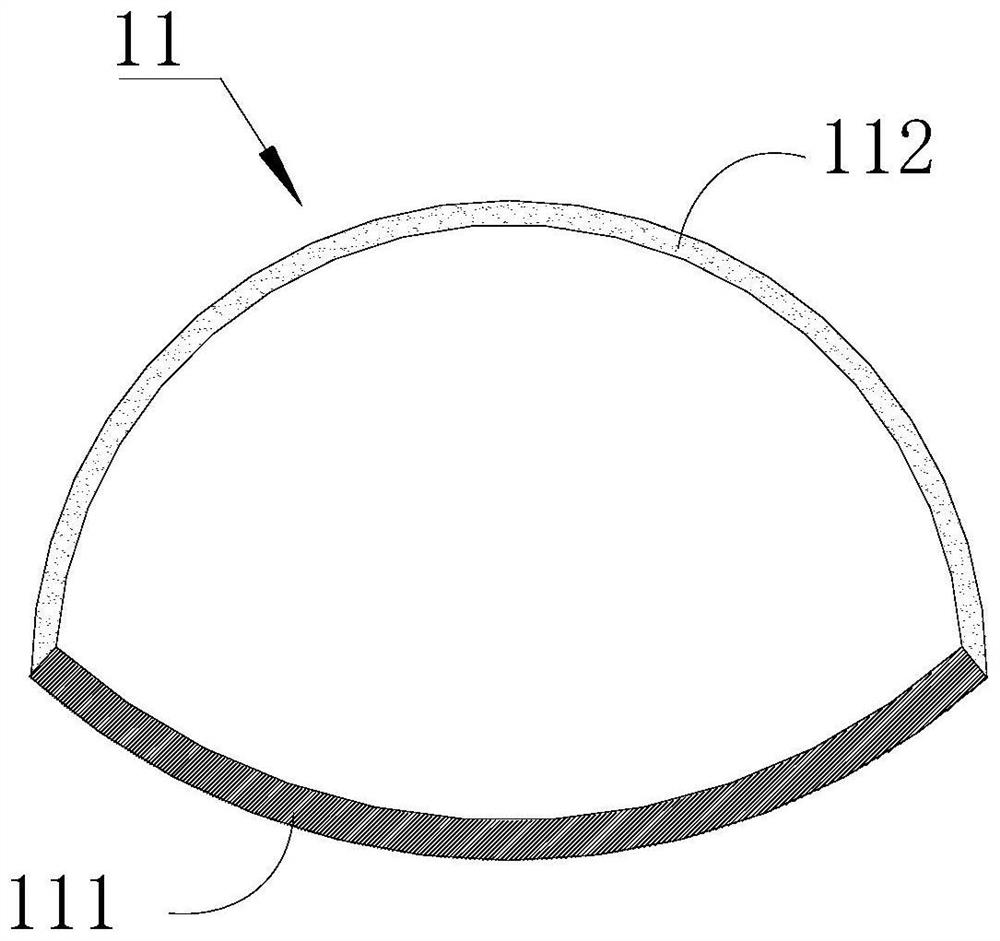

[0045] Specific embodiment 2: On the basis of specific embodiment 1, please refer to Figure 7-8 A kind of special-purpose heat insulating film net for keeping tea leaves active by nanotechnology, a plurality of mesh filaments 1 are interwoven into a mesh without voids by a cross interweaving method; The arc-shaped sheet 112 is at least partially spherical, and the arc-shaped sheet 112 is partially spherical, so that a large number of spherical arc-shaped sheets 112 are distributed on the surface of the membrane mesh. The corresponding internal gap where each mesh 1 is pressed by the anisotropic mesh 1 is at least partially opened, so that the gap is still continuous. The spherical shape enables sunlight from different directions in the sky to irradiate on the arc-shaped sheet 112 vertically, which improves the flexibility of the placement of the membrane mesh rather than being restricted by the placement position of the mesh wire 1 .

specific Embodiment 3

[0046] Specific embodiment three: on the basis of specific embodiment one or two, please refer to Figure 9 A special heat insulating film net for keeping tea leaves active by nanotechnology, the film net also includes a closed edge 3; the closed edge 3 is detachably connected with the fixed edge 2; during installation, the closed edge 3 is in sealing contact with the mesh 1 In order to close the gap; when disassembling, the closed edge 3 is separated from the mesh 1 to open the gap. At night, close both ends of the gap, so that the air in the gap that has absorbed the heat during the day is enclosed, and becomes a heat source at night, supplementing heat to the tea tree canopy, so that the temperature difference in the tea tree canopy throughout the day will not be too large. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com