Shelf for whole-age factory silkworm breeding and cleaning method thereof

A technology of shelf and breeding area, applied in the field of breeding, can solve the problems of low efficiency, low silkworm cocoon output, easy to leave feed, excrement, etc., and achieve the effect of high cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

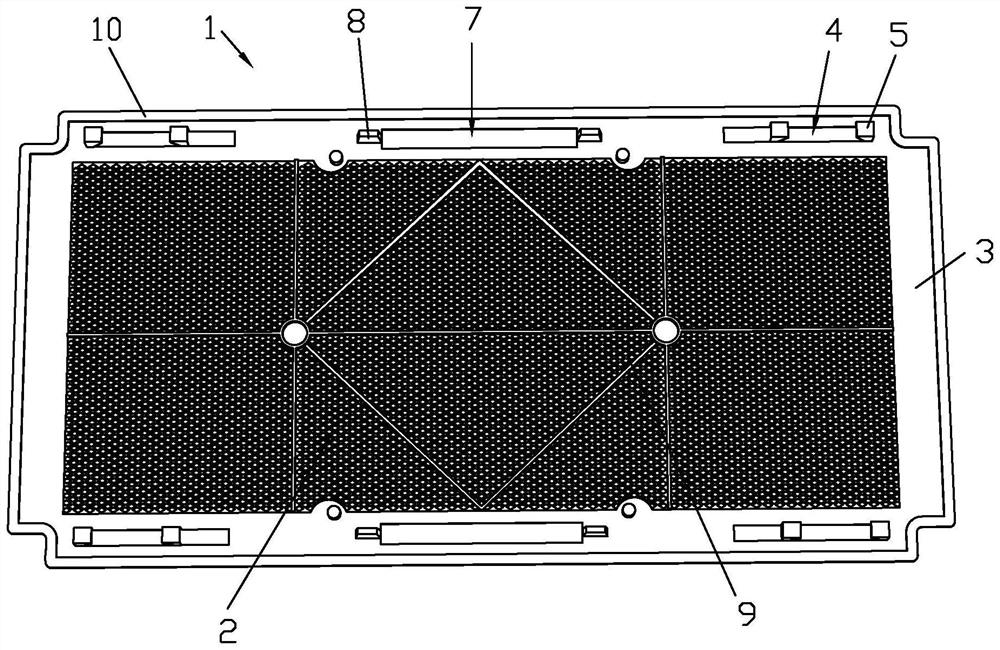

[0037] like figure 1 A kind of full-age factory silkworm rearing shelf 1 is shown, the shelf 1 is provided with a breeding area 2 of mesh holes and a placement area 3 around, and the placement area 3 is provided with a grab groove 4, and both ends of the grab groove 4 are provided with handle 5. The setting of the grab groove 4 and the handle 5 is convenient for the manipulator to grab the shelf 1 , so as to realize the movement of the shelf 1 , such as transferring and turning over.

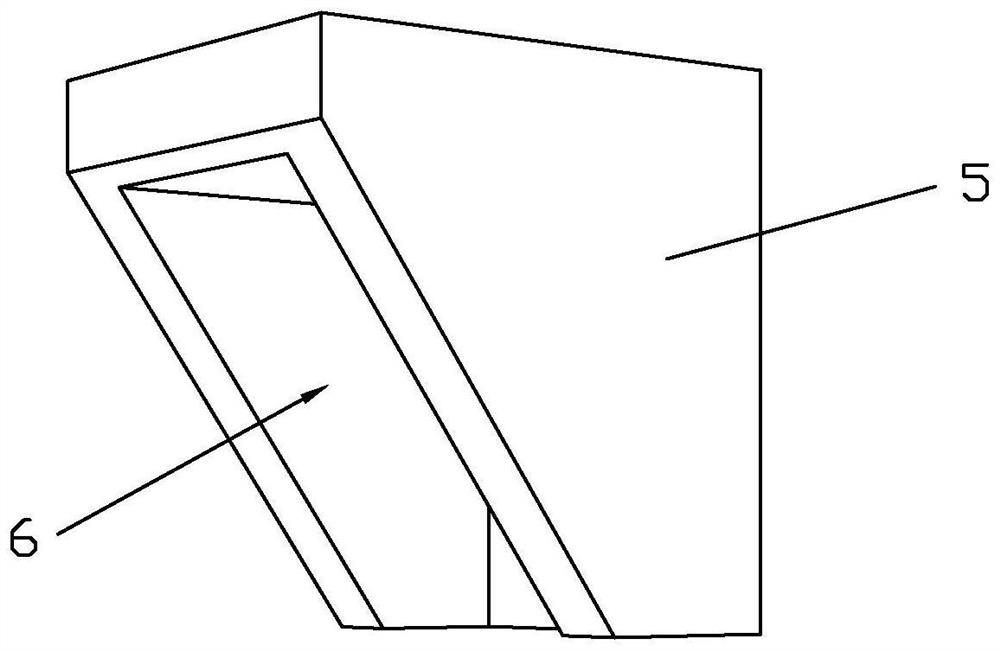

[0038] like figure 2As shown, the handle 5 is wide at the top and narrow at the bottom, one side of the handle 5 is provided with a vertical surface, the other side of the handle 5 is provided with an inclined surface, and the inclined surface is provided with a groove 6 . There is a groove 6 on the inclined surface of the handle 5. The groove 6 is wide at the top and narrow at the bottom, which is convenient for the manipulator to grasp, improves the stability of the shelf 1 when it is moved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com